TorchRed77Vette

Member

- Joined

- Nov 18, 2014

- Location

- Pickens

So a few of you expressed interest on how I design my custom bumpers. This process will let y'all scan anything into the computer with reasonable accuracy (I get <.10" error over the width of a truck), and with some practice in 3D design, will allow y'all to design what ever you dream up. Yes, it does take a CNC table to turn a lot of those ideas into reality but SOME fabrication shops love to see people build their own stuff and will cut parts for people who want to fabricate at home.

Please take note, that we are pushing the technology here, so play with it a little, and also having a beefy CAD computer is a necessity, but if you're planning on computer designing, this shouldn't be a surprise. And I don't want to scare anybody off, but it does take a good bit of understanding of computers and 3D design to get this to work well. Rest assure, the Internet knows all, and you might just have to do a little extra reading to get it going.

1. Strip the bumpers off the truck. You'll want to have good view of the mounting points you want to use.

2. Here's the magic. You'll want to find one of the original xbox 360 Kinect sensors (360 kinect sensors have a aux power supply which is necessary). These pack a decently high quality IR matrix projector and camera.

3. This is a big step here: With a windows computer, install the drivers and programs in the specified order. This youtube video does a good job documenting the steps, and the links along with a written guide is in the description of the video.

4. After you get all the drivers installed you need to download a scanning program and install it. I use ReconstructMe its very basic and will allow you to scan most stuff.

5. Plug in the kinect into wall and into the computer's USB. Start program and adjust your scan envelope and scan away.

Remember when I said you need to play with it, well this is where you'll be playing . It takes some getting used to to get a good scan, things I've learned: It doesn't like shiny objects or glass, so dirty trucks are best, you might have to cover chrome up to get a good scan. Don't go back and forth, just take one slow pass.

. It takes some getting used to to get a good scan, things I've learned: It doesn't like shiny objects or glass, so dirty trucks are best, you might have to cover chrome up to get a good scan. Don't go back and forth, just take one slow pass.

6. After you get a good scan, Save it as a STL.

7. Once you have your surface file you can load it into your favorite modeling program and design away!

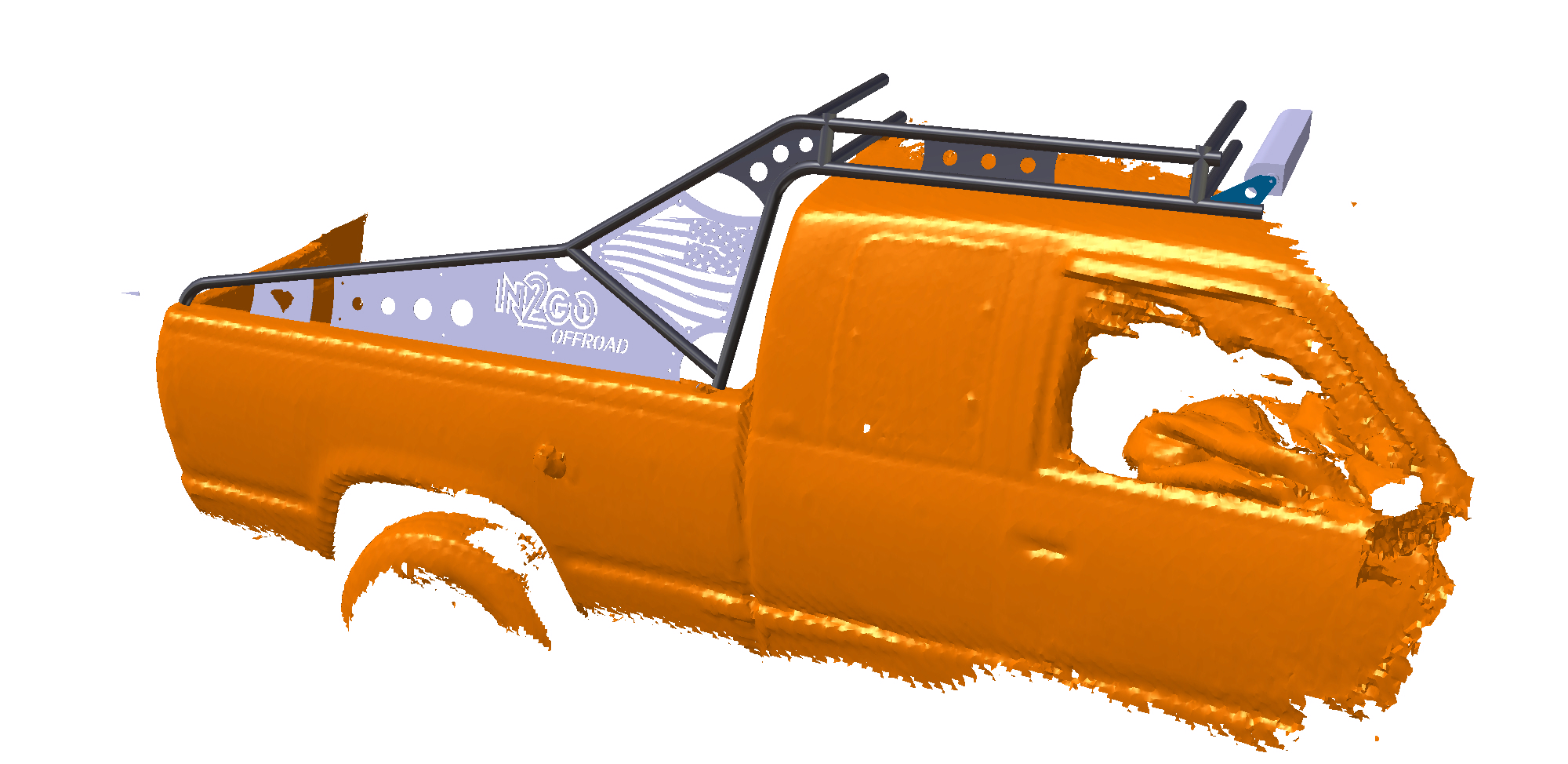

Here's an example of the Chase Rack for our Shop Truck:

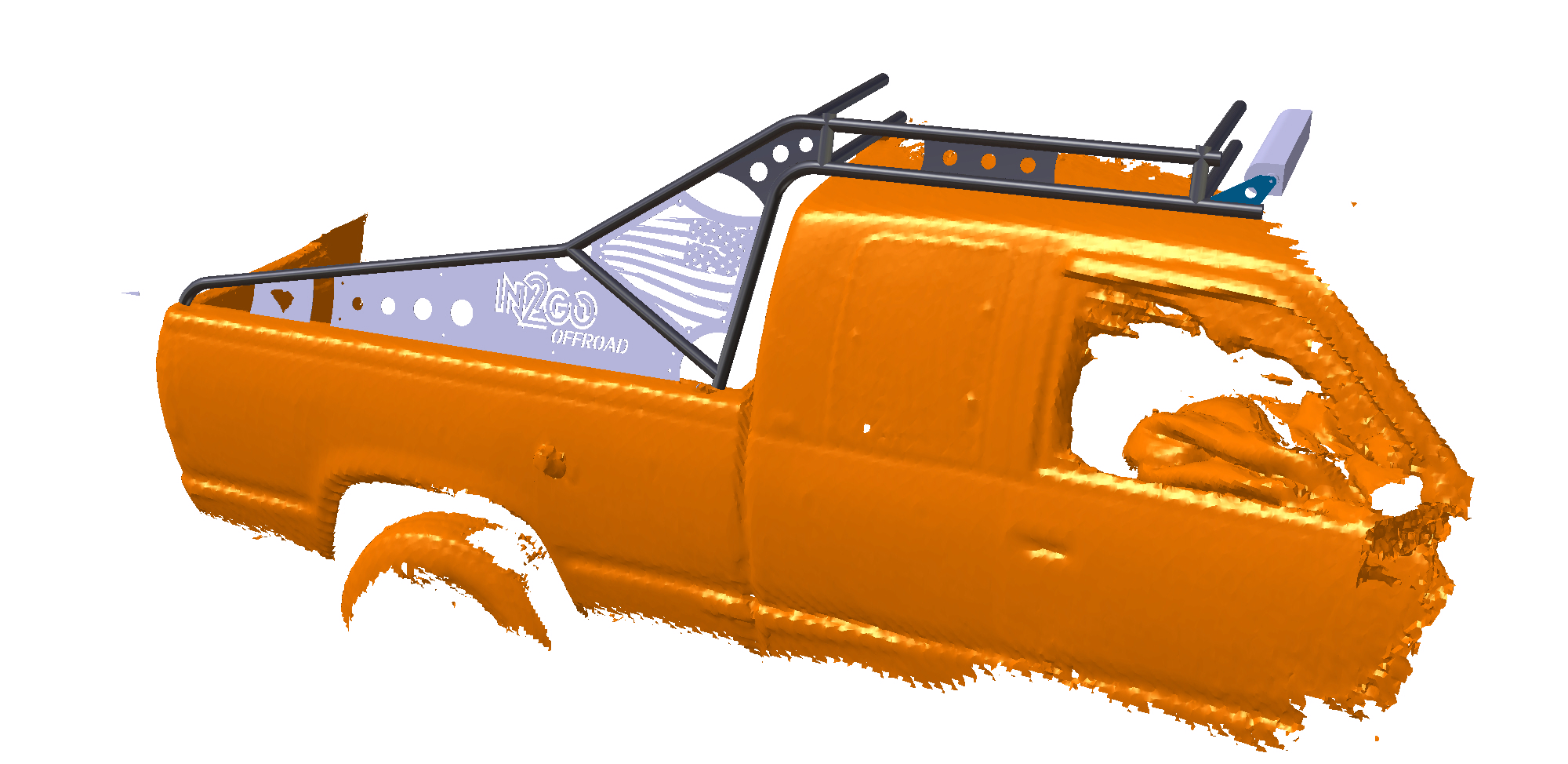

And voila:

Good Luck!!

Please take note, that we are pushing the technology here, so play with it a little, and also having a beefy CAD computer is a necessity, but if you're planning on computer designing, this shouldn't be a surprise. And I don't want to scare anybody off, but it does take a good bit of understanding of computers and 3D design to get this to work well. Rest assure, the Internet knows all, and you might just have to do a little extra reading to get it going.

1. Strip the bumpers off the truck. You'll want to have good view of the mounting points you want to use.

2. Here's the magic. You'll want to find one of the original xbox 360 Kinect sensors (360 kinect sensors have a aux power supply which is necessary). These pack a decently high quality IR matrix projector and camera.

3. This is a big step here: With a windows computer, install the drivers and programs in the specified order. This youtube video does a good job documenting the steps, and the links along with a written guide is in the description of the video.

4. After you get all the drivers installed you need to download a scanning program and install it. I use ReconstructMe its very basic and will allow you to scan most stuff.

5. Plug in the kinect into wall and into the computer's USB. Start program and adjust your scan envelope and scan away.

Remember when I said you need to play with it, well this is where you'll be playing

. It takes some getting used to to get a good scan, things I've learned: It doesn't like shiny objects or glass, so dirty trucks are best, you might have to cover chrome up to get a good scan. Don't go back and forth, just take one slow pass.

. It takes some getting used to to get a good scan, things I've learned: It doesn't like shiny objects or glass, so dirty trucks are best, you might have to cover chrome up to get a good scan. Don't go back and forth, just take one slow pass. 6. After you get a good scan, Save it as a STL.

7. Once you have your surface file you can load it into your favorite modeling program and design away!

Here's an example of the Chase Rack for our Shop Truck:

And voila:

Good Luck!!

Last edited: