orange150

Well-Known Member

- Joined

- Mar 20, 2005

- Location

- Fairfax City, VA

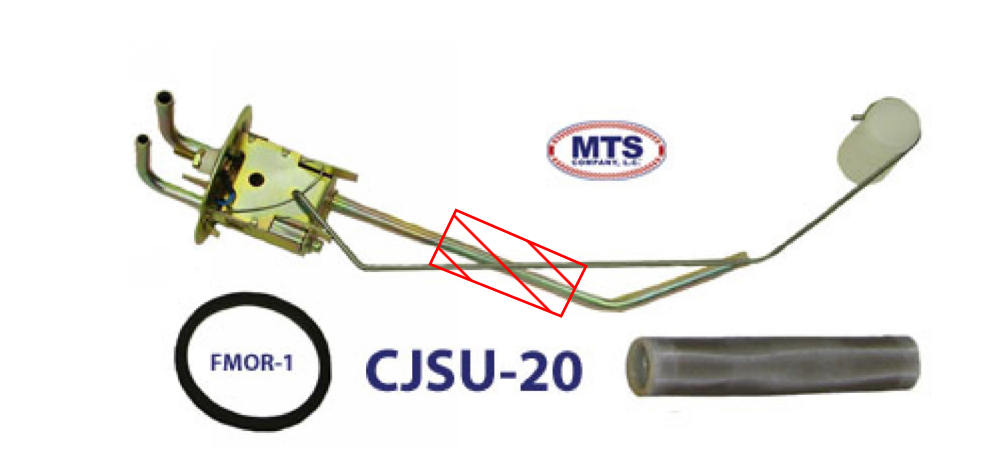

I keep going back and for on which type of fuel pump I want to run once I switch to FI in the Jeep... currently leaning towards making my own in tank pump using the OE fuel pick up/sending unit.

The OE 20gallon tanks in the CJs need to have that kink in the pick up tube to reach the lowest point of the sump. Because of that, I'm thinking the best place to install the pump would be just before the bend. Would starvation be an issue if it wasn't the absolute lowest point on the pickup?

If that's not an issue, the next thing I'm worried about is running the wiring safely. Is it as simple as making some studs and using simple screw hardware and lock nuts? I'd hate to get all explodey one day.

The OE 20gallon tanks in the CJs need to have that kink in the pick up tube to reach the lowest point of the sump. Because of that, I'm thinking the best place to install the pump would be just before the bend. Would starvation be an issue if it wasn't the absolute lowest point on the pickup?

If that's not an issue, the next thing I'm worried about is running the wiring safely. Is it as simple as making some studs and using simple screw hardware and lock nuts? I'd hate to get all explodey one day.