CarolinaHD

Well-Known Member ?

- Joined

- Dec 2, 2008

- Location

- Gold Hill

Put a gooseneck hitch on an old C50 2 ton and wanted some input on the design and strength of it.. Has a wooden bed on it that is in fantastic shape so the brackets had to be tall enough to reach the bottom of the bed floor.

Using a drawtite hitch bracket from Ebay

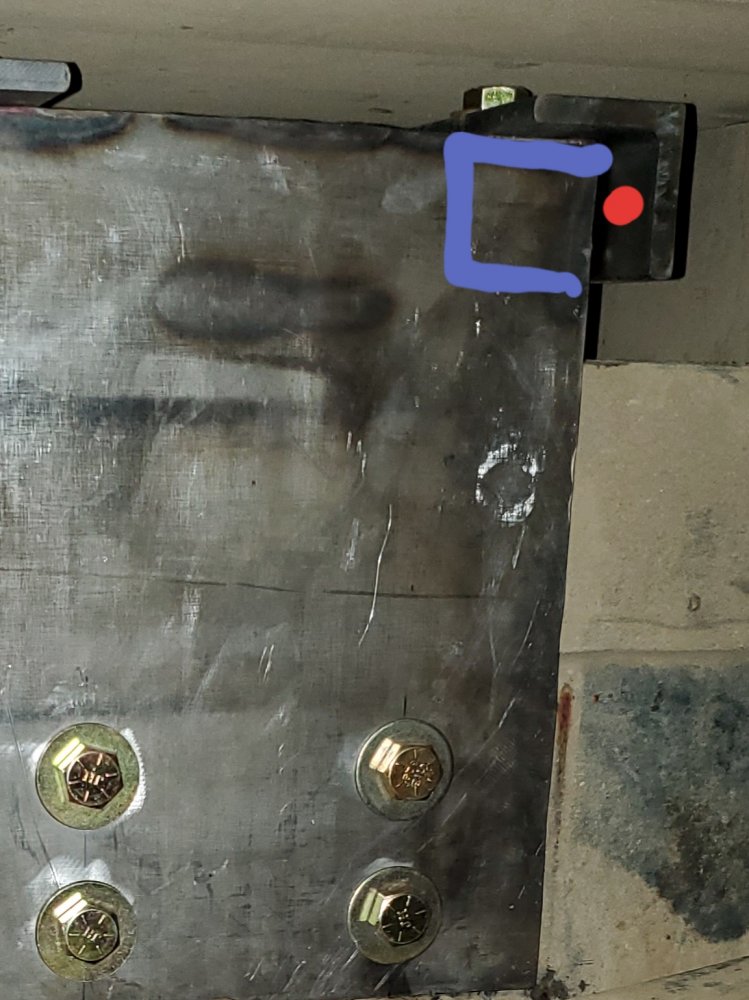

3/8" plate, 11" wide by 14" tall

2.5" by 3/8" angle

Grade 8- 5/8" hardware

Theres 6 bolts holding the angle to the gooseneck plate,4 bolts for the angle to the side brackets, and 8 bolts to the truck frame.

Questions are:

Should I weld in a piece to stiffen the 3/8" plate to help with side to side load? 2.5" wide and tall as the side plate. Red line in pic

Should I add more bolts between the angle bracket and plate? Thinking of putting in a small piece of angle in the corner, welding it to the plate and bolting it through the angle.

Weld where its blue and bolt through where its red

In the pic.

Hope this all makes sense

Using a drawtite hitch bracket from Ebay

3/8" plate, 11" wide by 14" tall

2.5" by 3/8" angle

Grade 8- 5/8" hardware

Theres 6 bolts holding the angle to the gooseneck plate,4 bolts for the angle to the side brackets, and 8 bolts to the truck frame.

Questions are:

Should I weld in a piece to stiffen the 3/8" plate to help with side to side load? 2.5" wide and tall as the side plate. Red line in pic

Should I add more bolts between the angle bracket and plate? Thinking of putting in a small piece of angle in the corner, welding it to the plate and bolting it through the angle.

Weld where its blue and bolt through where its red

In the pic.

Hope this all makes sense