YJJPWrangler

Well-Known Member

- Joined

- Jul 19, 2005

- Location

- Charlotte

I'll be moving to a new fuel cell for the willys soon because of clearance issues. TBI 4.3 out of a 1991 S10. Fuel pressure needs to be 10-15psi and a return line. I'm planning on purchasing either the 12g or 15gal RCI tank.

I'll mount it with either a Barnes4wd/Motobuilt etc type hold down.

I would really like to run an in tank style fuel pump as I have had issues in the past with inline fuel pumps.

Main question would be what type of fuel pump should I run? I was thinking a stock GM fuel pump like this

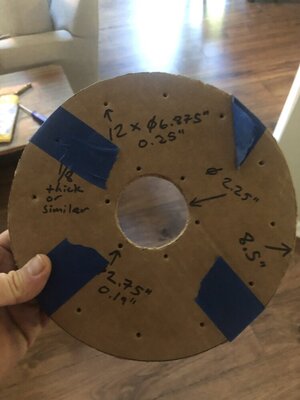

But I am concerned with how it will mount to the RCI tank. It looks like the tank comes with a sending unit for fuel level. What is everyone using?

I'll mount it with either a Barnes4wd/Motobuilt etc type hold down.

I would really like to run an in tank style fuel pump as I have had issues in the past with inline fuel pumps.

Main question would be what type of fuel pump should I run? I was thinking a stock GM fuel pump like this

But I am concerned with how it will mount to the RCI tank. It looks like the tank comes with a sending unit for fuel level. What is everyone using?