- Joined

- Mar 17, 2005

- Location

- N. N. Raleigh, NC

Long time since I've done any updates. I wanted to post a few pics of my fuel pump setup.. I put a lot of thought into the setup in effort to eliminate any issues I could for see..

I wanted to switch to an in tank pump, as they tend to be quieter and simpler. I was running a E2000 pump and really HATED the messy hose clamp setup to secure anything to the pump.. I know everyone had their own way to do it 'right' and many even mention using other pumps that 'were better' but fact is these people were unable to provide part numbers or even pics of their setup.. I was tired of wasting $ on adapters, fittings and junk for a sloppy install..

I initially was going to reuse the YJ intank mounting flange in my fuel cell. It was a good package and had a rubber plug that allowed 2 wires to pass into the tank. I wasn't so anal about things it would have sufficed.. Then after additional consideration I realized by the time I modifed everything about it to work with my AN hoses, change to a GM fuel sender add a vent etc. I really was no further ahead with this setup.. So I scraped it and started from scratch..

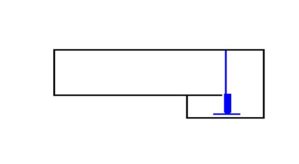

Flange - I chose to use a standard fuel cell 12 bolt flange gasket as a base as replacement gaskets and hardware kits are readilay avaliable and cheep. I made a small plate from 1/8" and drilled the 12 holes.

Fittings - I wanted to maintain a tight clean look and not have fitting that stood up 4-6" like I see on most fuel cells. I'm using standard 90 deg bulkhead fittings. I upgraded the nylon washers to heavier thicker washers while I was ordering other nylon items for the electrical components.

Vent - I spent a while figuring out how to get a good vent and roll over valve on the tank.. I bought a standard fuel cell rattle valve and they work fine, but it would have stuck up 2-3" even with a tight 90deg elbow on it.. nope.... I then realized the OEM YJ plastic valve would work perfect. I drilled a 1-1/4" hole and the original gromet and fiting works perfect and looks great to.. AND not I don't need a huge ass -6 hose for no reason other than to vent the tank.. I can use some 1/4" hose..

Electrical - I spent a long while researching this and was not able to find any commercial products. I was originally going to reuse the YJ harness but by the time I was done I'd be reusing a rubber plug and hacking a bunch of junk together.. No one had any advise other than to reuse an existing harness or some odd ball BNC connectors.. Bahhhh I made my own.. I noticed that the fuel sender pass the 'hot' wire through the mounting flange with a small SS bolt isolated with some nylon washers.. Bingo.. I order just the right size stepped nylon washers to fit a #10-24 SS machine screw and some misc. washers etc.. I assembled the parts, and did some testing, it all checked out good..

Pump - Im using a standard $40 GM intank pump they used on many many cars and trucks. Its an A list item and generally in stock most parts stores.. It came with some electrical leads in case your vehicle had damaged wires or pig tail etc.. So I basically used those parts and made my own mini harness.. I ran wires for both +/- to eliminate any potential grounding issues with the tank and/or flange gaskets etc.. And it also gives me a good place to secure the fuel level sender ground..

Hanger - I used some 5/16" steel rod and made a small plate on the bottom that uses the OEM isolator gasket to support the pump from the bottom. I added a hose clamp just in case but the hard line and hose holds it pretty well as is..

Return - Free standing hard line points just to the side of the inlet sock filter. Figured it might help blow any debris away from the filter down the road..

Setup seems to be working fine.. It pumps a consistent whopping 11psi !! Perfect as thats middle of the GM required 9-12 range for the TBI systems to run properly.. No pressure fall off either..

Ok some pics...

I wanted to switch to an in tank pump, as they tend to be quieter and simpler. I was running a E2000 pump and really HATED the messy hose clamp setup to secure anything to the pump.. I know everyone had their own way to do it 'right' and many even mention using other pumps that 'were better' but fact is these people were unable to provide part numbers or even pics of their setup.. I was tired of wasting $ on adapters, fittings and junk for a sloppy install..

I initially was going to reuse the YJ intank mounting flange in my fuel cell. It was a good package and had a rubber plug that allowed 2 wires to pass into the tank. I wasn't so anal about things it would have sufficed.. Then after additional consideration I realized by the time I modifed everything about it to work with my AN hoses, change to a GM fuel sender add a vent etc. I really was no further ahead with this setup.. So I scraped it and started from scratch..

Flange - I chose to use a standard fuel cell 12 bolt flange gasket as a base as replacement gaskets and hardware kits are readilay avaliable and cheep. I made a small plate from 1/8" and drilled the 12 holes.

Fittings - I wanted to maintain a tight clean look and not have fitting that stood up 4-6" like I see on most fuel cells. I'm using standard 90 deg bulkhead fittings. I upgraded the nylon washers to heavier thicker washers while I was ordering other nylon items for the electrical components.

Vent - I spent a while figuring out how to get a good vent and roll over valve on the tank.. I bought a standard fuel cell rattle valve and they work fine, but it would have stuck up 2-3" even with a tight 90deg elbow on it.. nope.... I then realized the OEM YJ plastic valve would work perfect. I drilled a 1-1/4" hole and the original gromet and fiting works perfect and looks great to.. AND not I don't need a huge ass -6 hose for no reason other than to vent the tank.. I can use some 1/4" hose..

Electrical - I spent a long while researching this and was not able to find any commercial products. I was originally going to reuse the YJ harness but by the time I was done I'd be reusing a rubber plug and hacking a bunch of junk together.. No one had any advise other than to reuse an existing harness or some odd ball BNC connectors.. Bahhhh I made my own.. I noticed that the fuel sender pass the 'hot' wire through the mounting flange with a small SS bolt isolated with some nylon washers.. Bingo.. I order just the right size stepped nylon washers to fit a #10-24 SS machine screw and some misc. washers etc.. I assembled the parts, and did some testing, it all checked out good..

Pump - Im using a standard $40 GM intank pump they used on many many cars and trucks. Its an A list item and generally in stock most parts stores.. It came with some electrical leads in case your vehicle had damaged wires or pig tail etc.. So I basically used those parts and made my own mini harness.. I ran wires for both +/- to eliminate any potential grounding issues with the tank and/or flange gaskets etc.. And it also gives me a good place to secure the fuel level sender ground..

Hanger - I used some 5/16" steel rod and made a small plate on the bottom that uses the OEM isolator gasket to support the pump from the bottom. I added a hose clamp just in case but the hard line and hose holds it pretty well as is..

Return - Free standing hard line points just to the side of the inlet sock filter. Figured it might help blow any debris away from the filter down the road..

Setup seems to be working fine.. It pumps a consistent whopping 11psi !! Perfect as thats middle of the GM required 9-12 range for the TBI systems to run properly.. No pressure fall off either..

Ok some pics...

I didn't use alum. fuel line, thats standard old 3/8" coated steel hard line. Got any 3/8"

I didn't use alum. fuel line, thats standard old 3/8" coated steel hard line. Got any 3/8"