Croatan_Kid

How's your hammer hangin'?

- Joined

- Nov 4, 2007

- Location

- New Bern

I have access to and can operate a full CNC machine shop (lathes with live tooling/mills), a CNC flame cutter, and 450 Miller welders. I've got the plans roughly sketched out in my mind and it'll be fairly easy, I just want some input from some other guys.

This is going in my 86 K30. I figure I'll start with a basic rectangle to go under the bed and across the frame rails. Depending on where there's a flat spot on the top of the rails will determine how long I'll make it. I'm thinking I want to somewhat mimmick some of the flip over setups that are on the market. I could cut out a square/circle for the ball to sit in and have a spring loaded handle to pull and turn so I can flip it. It doesn't have to flip, but I want it removeable. I could either buy a ball or machine one and then heat treat it.

I'm going to try to design this thing so I can install it on the truck and hopefully not have to remove or unbolt the bed. I haven't taken the time to go look all up under the truck lately though.

That's the jist of it. Now for the questions/concerns:

How thick of a plate should I use? 1/2, 3/4, 1"? I'll measure and see what'll fit. It's probably going to be T1 anyway, unless that would be less desireable than standard A36 mild steel.

I'll measure and see what'll fit. It's probably going to be T1 anyway, unless that would be less desireable than standard A36 mild steel.

I'd guess you want the ball to be juuuuust a hair forward of the rear axle, right?

Thinking of adding some perpendicular gusseting under the top plate to help stiffen it up.

We manufacture container tie downs at work, so the safety chain loops are no problem.

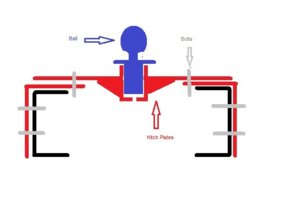

Should I come down the side of the frame rails with some plates just to get some extra bolts holding this jewel to the frame? I was envisioning 2 or 3 holes in the top of each frame rail. I suppose it would be more sturdy with side plates.

I already have a trailer brake controller (Hopkins interia sensing) and it's always worked great. The 7 pin is in my rear bumper where a normal civilian truck would have a license plate light. Should I make an extension to run up in the bed or should I run some wires and permanently mount one somewhere in the bed?

When I get done this should be way more beefy, some would say overkill, than anything you can buy. Any concerns or comments would be great. Maybe even some pics of your setup.

EDIT: Depending on how much room I have to work with, I may go for an inside the frame rail setup with some 1/2" wall tubing and some "C" brackets to bolt to the top and bottom of the frame rails. Just a thought.

This is going in my 86 K30. I figure I'll start with a basic rectangle to go under the bed and across the frame rails. Depending on where there's a flat spot on the top of the rails will determine how long I'll make it. I'm thinking I want to somewhat mimmick some of the flip over setups that are on the market. I could cut out a square/circle for the ball to sit in and have a spring loaded handle to pull and turn so I can flip it. It doesn't have to flip, but I want it removeable. I could either buy a ball or machine one and then heat treat it.

I'm going to try to design this thing so I can install it on the truck and hopefully not have to remove or unbolt the bed. I haven't taken the time to go look all up under the truck lately though.

That's the jist of it. Now for the questions/concerns:

How thick of a plate should I use? 1/2, 3/4, 1"?

I'll measure and see what'll fit. It's probably going to be T1 anyway, unless that would be less desireable than standard A36 mild steel.

I'll measure and see what'll fit. It's probably going to be T1 anyway, unless that would be less desireable than standard A36 mild steel.I'd guess you want the ball to be juuuuust a hair forward of the rear axle, right?

Thinking of adding some perpendicular gusseting under the top plate to help stiffen it up.

We manufacture container tie downs at work, so the safety chain loops are no problem.

Should I come down the side of the frame rails with some plates just to get some extra bolts holding this jewel to the frame? I was envisioning 2 or 3 holes in the top of each frame rail. I suppose it would be more sturdy with side plates.

I already have a trailer brake controller (Hopkins interia sensing) and it's always worked great. The 7 pin is in my rear bumper where a normal civilian truck would have a license plate light. Should I make an extension to run up in the bed or should I run some wires and permanently mount one somewhere in the bed?

When I get done this should be way more beefy, some would say overkill, than anything you can buy. Any concerns or comments would be great. Maybe even some pics of your setup.

EDIT: Depending on how much room I have to work with, I may go for an inside the frame rail setup with some 1/2" wall tubing and some "C" brackets to bolt to the top and bottom of the frame rails. Just a thought.

Last edited: