2" ram with a 1.25" rod at 1300 PSI (modded P-Pump) will make about 2500 pounds of force.

2.5" ram with a 1.5" rod at 1300 PSI will make about 4000 pounds of force.

Was asking what the above forces look like using the TG/PSC rams with smaller rods?

According to an online calc, it basically doubles the "

rod side" pressure...

Pressure acting on rod side

2" Piston diameter - d2 (in)

1.5" Rod diameter - d1 (in)

1300# Cylinder pressure - P1 (psi)

Force Rod Side - F1 (lb): 1787 (2297# delta)

Pressure acting on rod side

2" Piston diameter - d2 (in)

0.75" Rod diameter - d1 (in)

1300# Cylinder pressure - P1 (psi)

Force Rod Side - F1 (lb): 3510 (574# delta)

Pressure acting on opposite of rod side

2" Piston diameter - d2 (in)

1300# Cylinder pressure - d2 (psi)

Force Opposite Rod Side - F2 (lb): 4084

With the above numbers, the force delta for these smaller rod rams are a lot less, so guessing that equates into a "less noticeable" L<>R steering difference running a SE ram?

Correct. And the small rod will buckle easier too.

Also my concern, since stock Jeeps using 11/16" TREs/etc. are obviously a "weak link", 3/4" rods in these rams cause me to wonder about failure rates.

Meaning, outside of NON-contact (bashed into rock) & installer (bad placement/geometry) issues, are y'all seeing regular failures? EDIT: I see

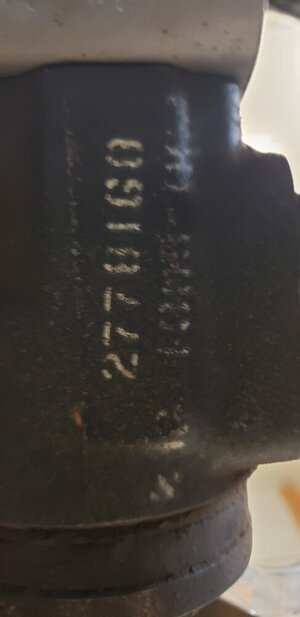

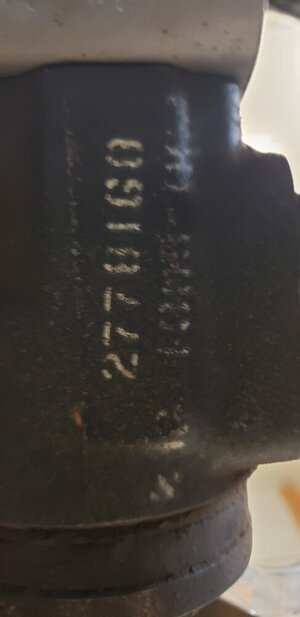

@Chris_Keziah was referencing the TG w/ 1.125" rods...

All this is finding my own "warm fuzzy", given the on-road part deciding between:

- 1.5" rod (harder to bend) w/ what appears to be VERY noticeable L-R-performance = keep the SC ram

- 3/4" rod (mounting better be dead nuts or

) w/ what appears to be 400% less noticeable L-R-performance = start over

but not opposed to starting over if the difference between 2" and 2.250"/2.5" will be that noticeable?

but not opposed to starting over if the difference between 2" and 2.250"/2.5" will be that noticeable? ) w/ what appears to be 400% less noticeable L-R-performance = start over

) w/ what appears to be 400% less noticeable L-R-performance = start over