Jeff B is getting ready to do a build on my cherokee. We are planning on using ford radius arms from a 78 f150. I've heard of some problems about the radius arms binding up when the suspension is flexed out... what are some ways we could solve this problem?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Radius Arm Knuckle?

- Thread starter multijeep

- Start date

paradisePWoffrd

Recovering Project Junkie

- Joined

- Nov 5, 2005

- Location

- Newton, NC

ive heard that running heims on the end of the arm adds some articulation.... also extending the arms out longer creates better susp geometry....

making one side wristed will also eliminates much of the binding, but youll want to make it pinned if the rig is driven on the road, or youll hate applying the brakes...

making one side wristed will also eliminates much of the binding, but youll want to make it pinned if the rig is driven on the road, or youll hate applying the brakes...

muddrunner1968

Active Member

- Joined

- Apr 20, 2007

- Location

- Lincolnton NC

just build a wristed radius arm set up. do a search on pirate there are some good threads on it.

braxton357

Robot

- Joined

- Apr 6, 2005

- Location

- Morganton

Having had both wristed and extended arms...extend them. And put a bend in them for tire clearance depending on what wheels you're running.

Rich

Asshole at large

- Joined

- Mar 17, 2005

- Location

- Central PA

If you're going to run leafs in the back still, a little binding isn't a bad thing, if you want it to be remotely balanced..

family xj

Well-Known Member

- Joined

- Feb 19, 2006

- Location

- Jacksonville NC

I built mine with radius arms using the Currie Johnny Joints and bent them for tire clearance. They don't flex nearly as well as I thought they were going to. I am going to look into building one with the wristing idea. You can check my profile and look for the posts to see how I built mine

drkelly

Dipstick who put two vehicles on jack stands

- Joined

- Mar 21, 2005

- Location

- Oak Ridge/Stokesdale, NC

I wristed the arm on mine, and pin it for driving on the street. No compaints, but I am planning on changing the frame end of the arms to a different joint.

mudonthetires10

Member

- Joined

- May 19, 2005

- Location

- Randolph County

Having both wristed and extended arms...extend them. And put a bend in them for tire clearance depending on what wheels you're running.

You aren't supposed to wrist both of them. Just one.

Jeff B

Thanos was right

- Joined

- Dec 23, 2006

- Location

- Lincolnton N.C.

I have the hardware to do thw wristing

Which side is recomended to be wristed or does it matter

Which side is recomended to be wristed or does it matter

family xj

Well-Known Member

- Joined

- Feb 19, 2006

- Location

- Jacksonville NC

I wristed the arm on mine, and pin it for driving on the street. No compaints, but I am planning on changing the frame end of the arms to a different joint.

You have any pics of yours? I might have to rebuild my Passenger one to be wristed.

braxton357

Robot

- Joined

- Apr 6, 2005

- Location

- Morganton

You aren't supposed to wrist both of them. Just one.

(meaning that I've had both a set of wristed arms and a set of lengthened-- with only one RA of the "set" of wristed arms actually being wristed--and both of the lengthened arms being lengthened.)

As for some of these questions--pinning them for the street is mostly unnecessary, any g8 bolt 3/4"+ will work, and you want to wrist the one furthest from the driveshaft. On a ford axle, that's the passenger side.

muddrunner1968

Active Member

- Joined

- Apr 20, 2007

- Location

- Lincolnton NC

mudonthetires10

Member

- Joined

- May 19, 2005

- Location

- Randolph County

My bad.(meaning that I've had both a set of wristed arms and a set of lengthened-- with only one RA of the "set" of wristed arms actually being wristed--and both of the lengthened arms being lengthened.)

Well....

...you should....

....work on being more concise.

How does that sound?

:tongue:

I was going to go with radius arms originally, but didn't end up going that route.

I would lengthen the arms and wrist, with Johnny Joints on the end.

Also, might want to consider reinforcing the sides of the arms or even cutting off the C and welding it to square tubing, etc...since you will have to cut there to wrist one of the arms anyway.

Check the Ford forum in Pirate. There are a plethora of examples.

braxton357

Robot

- Joined

- Apr 6, 2005

- Location

- Morganton

My bad.

Well....

...you should....

....work on being more concise.

How does that sound?

:tongue:

I was going to go with radius arms originally, but didn't end up going that route.

I would lengthen the arms and wrist, with Johnny Joints on the end.

Also, might want to consider reinforcing the sides of the arms or even cutting off the C and welding it to square tubing, etc...since you will have to cut there to wrist one of the arms anyway.

Check the Ford forum in Pirate. There are a plethora of examples.

The route you went is the way most people should go unless they have a ford axle with cast-in wedges. Radius arms are (sometimes) easy, but not that great--and as is obvious, you can end up with something much better if you link it from the beginning rather than go through all of the phases of RA's...

Also,

drkelly

Dipstick who put two vehicles on jack stands

- Joined

- Mar 21, 2005

- Location

- Oak Ridge/Stokesdale, NC

You have any pics of yours? I might have to rebuild my Passenger one to be wristed.

Here you go. It is just like all the others I have seen on the internet. I used a 1" diameter bolt for the pivot, and a 5/8" hitch pin to lock it.

66gasgrill

New Member

- Joined

- Nov 13, 2007

- Location

- Canton,NC

Those are the same arms as the early broncos. Extend them for sure. I went a little different route on the wristing tho. I uesd a wristed axle instead of a wristed arm. By wristing the axle you get rid of the C-bushing bind but you don't have to worry about pinning it for steet driving.

Look here to get an Idea of what I'm talking about. http://classicbroncos.com/wristedaxle.shtml

Do a search on there for extened radius arms. theres about 3 days worth of reading. Several of the Bronco houses make extended arms. Might check em out for some ideas. Good luck

Look here to get an Idea of what I'm talking about. http://classicbroncos.com/wristedaxle.shtml

Do a search on there for extened radius arms. theres about 3 days worth of reading. Several of the Bronco houses make extended arms. Might check em out for some ideas. Good luck

Jeff B

Thanos was right

- Joined

- Dec 23, 2006

- Location

- Lincolnton N.C.

got any pics?Those are the same arms as the early broncos. Extend them for sure. I went a little different route on the wristing tho. I uesd a wristed axle instead of a wristed arm. By wristing the axle you get rid of the C-bushing bind but you don't have to worry about pinning it for steet driving.

66gasgrill

New Member

- Joined

- Nov 13, 2007

- Location

- Canton,NC

try the link. I'll post some pics of mine after while. Got to pay my money first.

66gasgrill

New Member

- Joined

- Nov 13, 2007

- Location

- Canton,NC

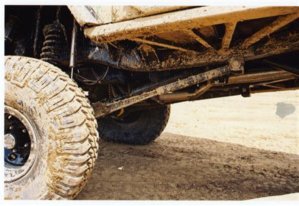

here's a couple pics first one shows how much bind is eliminated with the wristed axle. look at the angles of the radius arms. the oter is the assembly it self. it takes a beating.

We wheeled last weekend I still haven't cleaned it back up.

We wheeled last weekend I still haven't cleaned it back up.

Attachments

66gasgrill

New Member

- Joined

- Nov 13, 2007

- Location

- Canton,NC

family xj

Well-Known Member

- Joined

- Feb 19, 2006

- Location

- Jacksonville NC

What did that kit cost and how long to do it?

66gasgrill

New Member

- Joined

- Nov 13, 2007

- Location

- Canton,NC

Can't remember off hand somewhere aroound $400.00, go to BcBroncos.com and look for the WAH. You can make your own or use the kit from BC Broncos. Minus axle disassembly (you can leave the chunk in but make sure you stuff a rag in, to keep out shavings and such, and clean it out good after your done) I think it took about 1.5 -2 hours. Theres not a lot of welding just takes some time to make sure its plumb and square.