a_kelley

mechanical fixer

- Joined

- Jan 26, 2010

- Location

- Rutherfordton

OK so I figured since I had to repair a c0265 (pump relay failure) on a 2000 silverado 1500, I would document it and post it. You're supposed to replace the electronic brake control module for this code, however, you can repair it with some patience.

You'll need:

(No pics this step.)

Now that it is removed, lay it bottom side up and remove the six T8 bolts holding cover on. Not all units have bolts, depending on version.

Put the EBCM edgewise on the bench and take your razor and slice the sealer holding the cover on. All units are sealed shut. I try to take several passes to get 3 sides cut most the way through and gently pry and you can easily get it open. It takes a little patience.

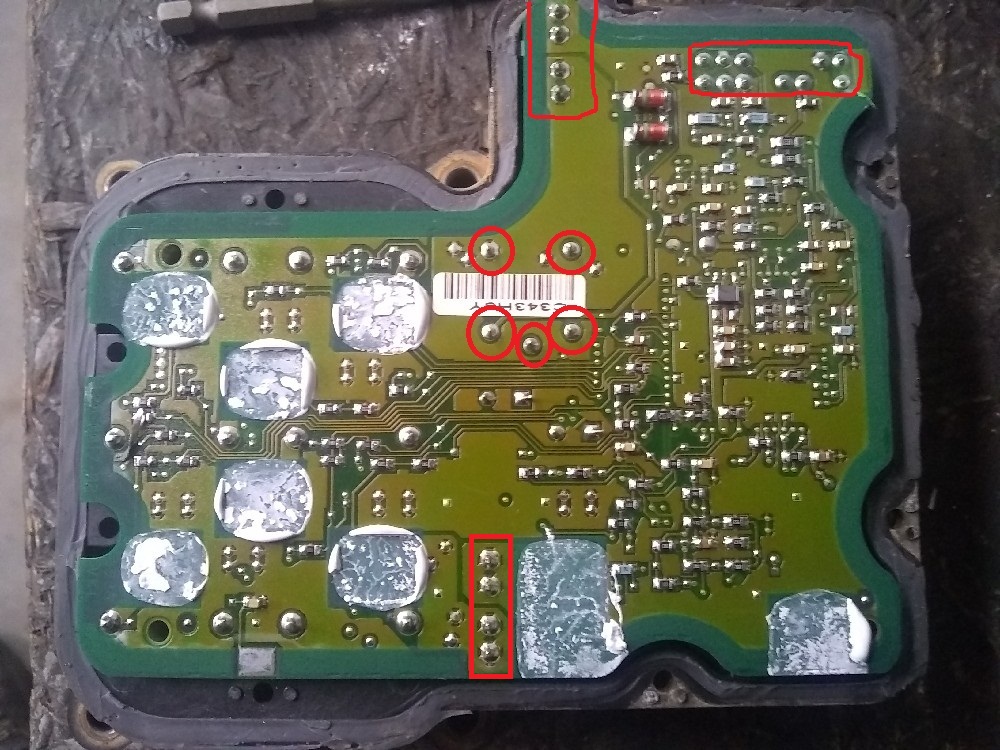

After it is split open and its innards are now outwards, you can resolder the cracked solder joints. Depending on revision this may differ from my board. However, generally it is the joints for the connectors and the relay. You can see them circled and will be similar in all units. You can use the micro torch for all the joints, as long as you are careful to only heat it enough to remelt the solder and add a little more. My 140w soldering gun did not have enough heat to satisfactorily resolder the connector joints.

Connections to inspect:

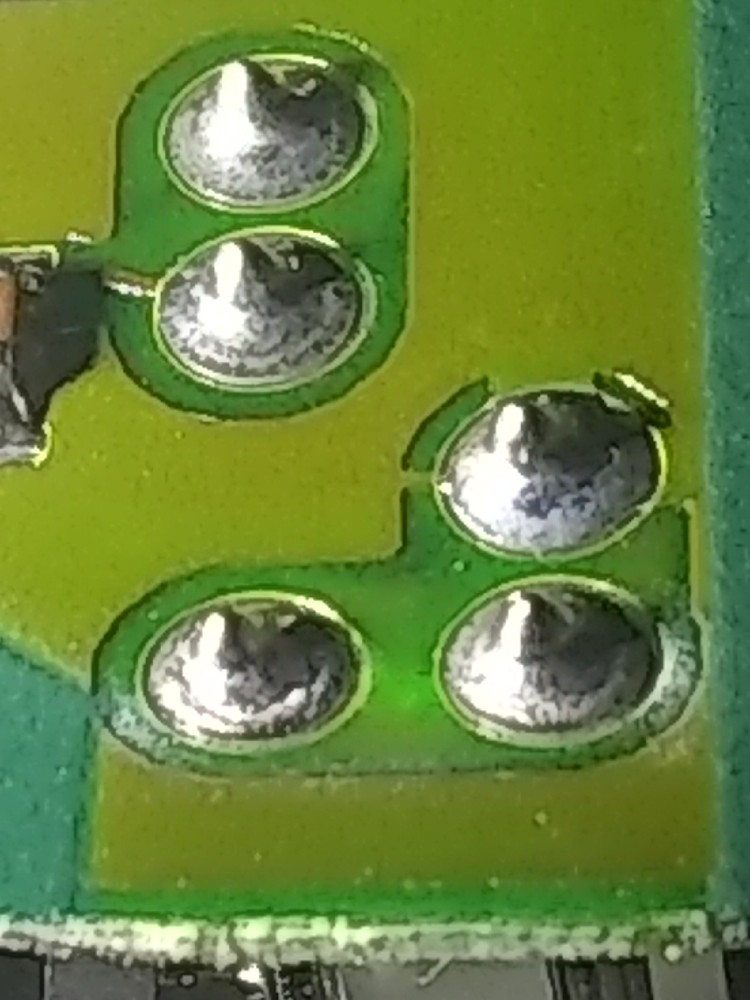

Cracked joint.

Soldering joints:

Resoldered joints & ready to assemble. Make 100% certain that you do not "bridge" joints by adding excess solder. Should you happen to bridge a joint, fine strand copper wire or copper wire braid will help to remove it (with additional flux to help the braid/wire draw the solder).

Once you have them resoldered the cracked joints and cleaned the flux off (and any others you wish to retouch while in there), put a dot of heat transfer grease on each white spot on the inside of the cover (if you dont have any, don't worry too much about it, as the ABS module only activates for short periods of time and I haven't had any longevity issues with not adding more grease), skim coat the perimeter of the lid and reassemble. Wipe off excess sealer that mushes out so you don't wear it reinstalling the EBCM.

Reinstall EBCM to hydraulic module.

Reset the EBCM codes & run a automated bleed to verify the repair. In absence of a scan tool, you might get by unhooking the battery or just test driving it. The first time you drive at 5-15 mph, the computer runs a brake test. You may have noticed the ABS & brake light does not come on immediately even when it is not working properly - that is due to the self test occurring while moving.

Final step - Enjoy not seeing the ABS & brake light being illuminated & ABS working. Considering the EBCM runs about $150-350, I'd say that its worthwhile to repair the module you already have that is failed. If you are scared of soldering, simply remind yourself that at worst, if you screw up, it blows a fuse, and does not work.

DISCLAIMER: Any repairs following this procedure are your liability, not mine. If for some reason in the course of you following this repair your truck burns to the ground, brakes fail while driving, you burn or cut yourself, it's entirely your problem and not mine. You assume all responsibility and liability from any and all successes and failures or any consequential or incidental or accidental damages, whether intentional or unintended. That being said, you should succeed in your repair if you reflow all the broken joints , unless the module is truly FUBAR'ed.

You'll need:

- A 90* pick

- T8 bit (long)

- T20 bit (short)

- T20 bit socket

- 1/4" (ratchet) wrench & 1/4" ratchet

- Micro torch

- 100w+ Soldering gun(optional)

- Fine flux core solder (.060 of your choice. My preference is lead/tin, seems to wet better)

- Isopropyl alcohol/non-chlorinated brake cleaner (to remove flux residue)

- Heat transfer grease (not required, but recommended)

- Good eyes

- Bright light & magnification

- Steady-ish hands

- Razor blade/knife

- Sealer (my preference is ultra grey, but you can use anything just so long as it does not smell like vinegar)

(No pics this step.)

Now that it is removed, lay it bottom side up and remove the six T8 bolts holding cover on. Not all units have bolts, depending on version.

Put the EBCM edgewise on the bench and take your razor and slice the sealer holding the cover on. All units are sealed shut. I try to take several passes to get 3 sides cut most the way through and gently pry and you can easily get it open. It takes a little patience.

After it is split open and its innards are now outwards, you can resolder the cracked solder joints. Depending on revision this may differ from my board. However, generally it is the joints for the connectors and the relay. You can see them circled and will be similar in all units. You can use the micro torch for all the joints, as long as you are careful to only heat it enough to remelt the solder and add a little more. My 140w soldering gun did not have enough heat to satisfactorily resolder the connector joints.

Connections to inspect:

Cracked joint.

Soldering joints:

Resoldered joints & ready to assemble. Make 100% certain that you do not "bridge" joints by adding excess solder. Should you happen to bridge a joint, fine strand copper wire or copper wire braid will help to remove it (with additional flux to help the braid/wire draw the solder).

Once you have them resoldered the cracked joints and cleaned the flux off (and any others you wish to retouch while in there), put a dot of heat transfer grease on each white spot on the inside of the cover (if you dont have any, don't worry too much about it, as the ABS module only activates for short periods of time and I haven't had any longevity issues with not adding more grease), skim coat the perimeter of the lid and reassemble. Wipe off excess sealer that mushes out so you don't wear it reinstalling the EBCM.

Reinstall EBCM to hydraulic module.

Reset the EBCM codes & run a automated bleed to verify the repair. In absence of a scan tool, you might get by unhooking the battery or just test driving it. The first time you drive at 5-15 mph, the computer runs a brake test. You may have noticed the ABS & brake light does not come on immediately even when it is not working properly - that is due to the self test occurring while moving.

Final step - Enjoy not seeing the ABS & brake light being illuminated & ABS working. Considering the EBCM runs about $150-350, I'd say that its worthwhile to repair the module you already have that is failed. If you are scared of soldering, simply remind yourself that at worst, if you screw up, it blows a fuse, and does not work.

DISCLAIMER: Any repairs following this procedure are your liability, not mine. If for some reason in the course of you following this repair your truck burns to the ground, brakes fail while driving, you burn or cut yourself, it's entirely your problem and not mine. You assume all responsibility and liability from any and all successes and failures or any consequential or incidental or accidental damages, whether intentional or unintended. That being said, you should succeed in your repair if you reflow all the broken joints , unless the module is truly FUBAR'ed.

Last edited: