Dawnpatrol

Jesse Higgins

- Joined

- Apr 25, 2016

- Location

- Raleigh

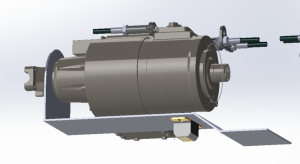

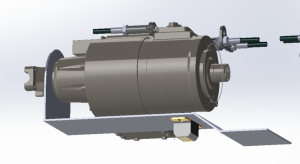

I'm working on my Dana 20 doubler setup, with and atlas style upgraded rear output, and I need to build a rear output support for the transfer case. The common style I have seen is a simple crossmember that mimics the transmission crossmember. This would end up being two separate cross member supports that are inline with each other. Then I got to thinking about a design that utilizes the single original trans crossmember and has a single mount that cradles the transfer case and transmission together (a single mounting plate). The attached picture that shows a "rough" sketch of what I am trying to describe. The transmission would bolt to the mounting plate and the mounting plate would haven an integral atlas support ring. I am mounting the transfercase/doubler to an AX15 that has the crossmember positioned slightly behind the transmission (YJ style).

What are others thoughts on this style of transfer case support?

Do you think it would be strong enough with proper thickness plate and gussets, or would it overload the poly mount?

Would it have the potential to cause too much stress on the trans and transfer case due to the support design and the torque going through the components?

What are others thoughts on this style of transfer case support?

Do you think it would be strong enough with proper thickness plate and gussets, or would it overload the poly mount?

Would it have the potential to cause too much stress on the trans and transfer case due to the support design and the torque going through the components?

).

).