You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

3-link track bar question, and many more!

- Thread starter strange1

- Start date

77GreenMachine

Phillip Talton

- Joined

- Mar 30, 2010

- Location

- Trinity, NC

It’s pretty typical to off set the track bar to clear the diff. It just need to be parallel with the drag link.

Perfect. Thank you.It’s pretty typical to off set the track bar to clear the diff. It just need to be parallel with the drag link.

DonYukon

Well-Known Member

- Joined

- Mar 15, 2021

- Location

- Fayetteville

This , the most important part is the geometry with the drag link. if they are on much different angles it begs for problems

WARRIORWELDING

Owner opperator Of WarriorWelding LLC.

- Joined

- Jan 6, 2008

- Location

- Chillin, Hwy 64 Mocksville NC

They don't worky so good if the pair make an "x" either........saw that before.

Another handy bit is the make them as close as you can identical in length from "pivoty" place to "pivoty" place. Both moving in the same plane and arc ratio is perfection.

Another handy bit is the make them as close as you can identical in length from "pivoty" place to "pivoty" place. Both moving in the same plane and arc ratio is perfection.

DonYukon

Well-Known Member

- Joined

- Mar 15, 2021

- Location

- Fayetteville

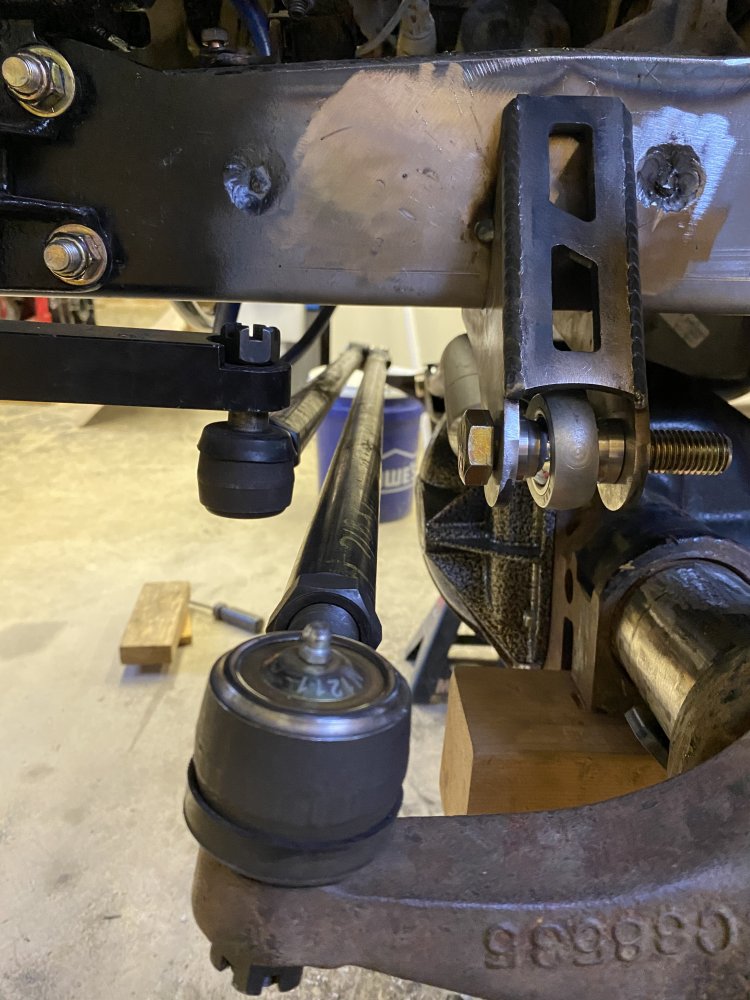

you should have ZERO issues with those angles. looks goodPretty close, but still needs a minor tweak (and maybe a bend). Now onto finding a spot for the upper link. View attachment 341342

Except the track-bar hitting the diff and the oil-pan.... hopefully a paychecks worth of bumpstops will help.you should have ZERO issues with those angles. looks good

DonYukon

Well-Known Member

- Joined

- Mar 15, 2021

- Location

- Fayetteville

From the last photo I seen the bars well forward of the diff

NickMaul

Well-Known Member

- Joined

- Jul 4, 2009

- Location

- Norfolk, VA

How far are you from full bump in that pic?Except the track-bar hitting the diff and the oil-pan.... hopefully a paychecks worth of bumpstops will help.

That pic is my projected ride height, there will probably not be more than 4” up travel. The axle has pushed forward a bit more since that first pic.How far are you from full bump in that pic?

Now that we have that settled, what size tube do the guru’s recommend for the upper link? I bought a tube/heim kit from @Barnes 4wd that came with 2x.250 for both the lowers and the upper. As you can see there’s not a lot of room for the upper link. Can I get away with 1.5”x something for the upper link?

77GreenMachine

Phillip Talton

- Joined

- Mar 30, 2010

- Location

- Trinity, NC

If you need the space it will be fine with 1.5” .250 wall for the upper. But you need to make darn good and sure that you get the upper link frame bracket welded in very good. Add a gusset if possible. There are extreme forces applied to it. I was recently wheeling with a buddy and his upper link mount let go due to a bad weld. That was on a Thursday evening in Harlan. Wiped out the front coilovers, his weekend was done for.

hurt4x4

Well-Known Member

- Joined

- Sep 12, 2012

- Location

- Greensboro

Looks like plenty of room on the driver's side, could you do a low profile truss and move it over?Now that we have that settled, what size tube do the guru’s recommend for the upper link? I bought a tube/heim kit from @Barnes 4wd that came with 2x.250 for both the lowers and the upper. As you can see there’s not a lot of room for the upper link. Can I get away with 1.5”x something for the upper link?View attachment 342107

I’m trying to stay fairly low. At full bump I can barely squeeze my hand between the diff and the oil pan.Looks like plenty of room on the driver's side, could you do a low profile truss and move it over?

- Joined

- Mar 20, 2005

- Location

- Hendersonville, NC

I once took 1.5" x.250", had it tapped for 1.25" joints. Solved both issues at once.

Now that we have that settled, what size tube do the guru’s recommend for the upper link? I bought a tube/heim kit from @Barnes 4wd that came with 2x.250 for both the lowers and the upper. As you can see there’s not a lot of room for the upper link. Can I get away with 1.5”x something for the upper link?View attachment 342107

You could cut and plate the frame for more clearance and "massage" the exhaust.

As everyone said, 1.5x.250 will be fine, the mounts are usually the issue.

So it seems that 1.5 x .250 wall it is. But now the question is do I tap it for 1-1/4 heims (I’ve already got the heims, but will have to buy both RH and LH taps and pay someone to put it on a lathe? Or do I use a 3/4 heim and weld in tube adapter (much cheaper in the end)?

that track bar is ugly, but just barely clears both the diff and the oil pan. I’m still not satisfied that it is the best solution.

that track bar is ugly, but just barely clears both the diff and the oil pan. I’m still not satisfied that it is the best solution.

Last edited:

- Joined

- Mar 13, 2005

- Location

- Raleigh, NC

That was on a Thursday evening in Harlan. Wiped out the front coilovers, his weekend was done for.

This is what 3-links do best.

hurt4x4

Well-Known Member

- Joined

- Sep 12, 2012

- Location

- Greensboro

My vote would be tapping for 1.25 heim, but I'd say either option would be pretty close as far as strength. Track bar looks pretty similar to what I had to do on my Tacoma.So it seems that 1.5 x .250 wall it is. But now the question is do I tap it for 1-1/4 heims (I’ve already got the heims, but will have to buy both RH and LH taps and pay someone to put it on a lathe? Or do I use a smaller heim and weld in tube adapter (probably a little cheaper in the end)? View attachment 342330

that track bar is ugly, but just barely clears both the diff and the oil pan. I’m still not satisfied that it is the best solution. View attachment 342331

- Joined

- Mar 24, 2005

- Location

- Stanley, NC

Some guys with lathes already have 1-1/4" RH and LH tapsSo it seems that 1.5 x .250 wall it is. But now the question is do I tap it for 1-1/4 heims (I’ve already got the heims, but will have to buy both RH and LH taps and pay someone to put it on a lathe? Or do I use a 3/4 heim and weld in tube adapter (much cheaper in the end)? View attachment 342330

that track bar is ugly, but just barely clears both the diff and the oil pan. I’m still not satisfied that it is the best solution. View attachment 342331

Do you know of anyone convenient to I77 between north Charlotte and Elkin?Some guys with lathes already have 1-1/4" RH and LH taps

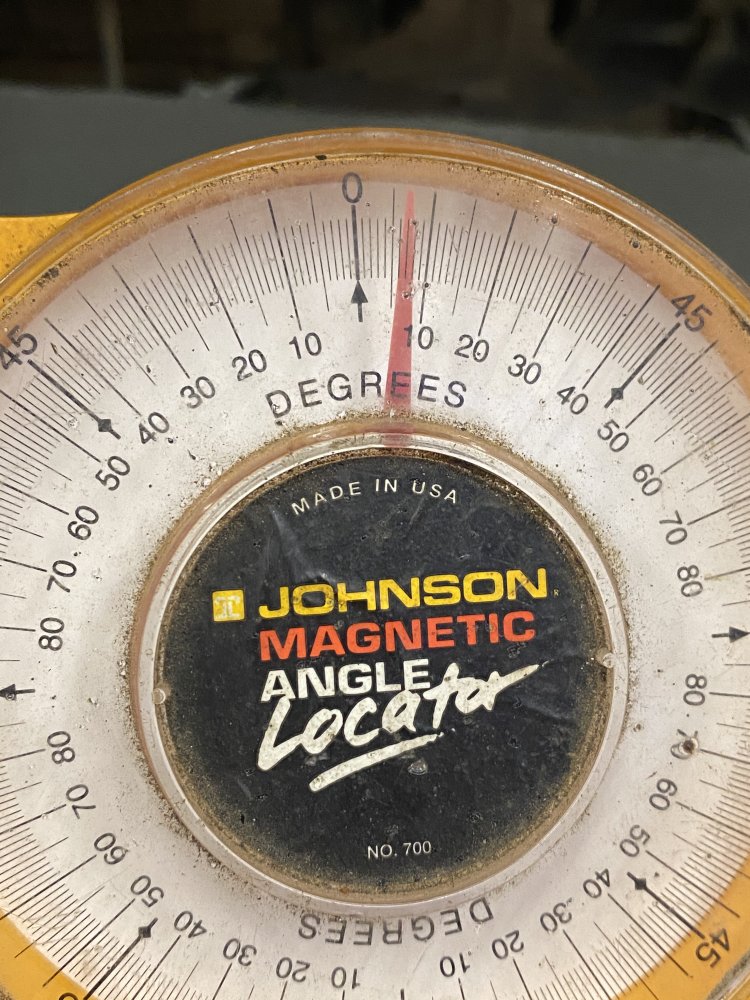

My plastic angle finder sitting on top of a 35 year old, finger tight, ball joint isn’t the most scientific method; but it looks like I may have gotten lucky.

Full bump

Ride height

Full droop

full bump/steering straight

and full lock turning left, the reason I can’t push my track bar away from the diff. It’s hard to see how close the tie rod is because my phone focused on the TRE. I’ll probably end up having to limit the drivers side bump to about an inch lower than the passenger side, but I doubt if anyone would ever notice it I don’t point that out.

Full bump

Ride height

Full droop

full bump/steering straight

and full lock turning left, the reason I can’t push my track bar away from the diff. It’s hard to see how close the tie rod is because my phone focused on the TRE. I’ll probably end up having to limit the drivers side bump to about an inch lower than the passenger side, but I doubt if anyone would ever notice it I don’t point that out.

My vote would be tapping for 1.25 heim, but I'd say either option would be pretty close as far as strength. Track bar looks pretty similar to what I had to do on my Tacoma.

Do you have a bushing on one end, or heims on both? If heims, do you have trouble with the bar ‘rolling’ forward or back on the heims and causing interference?

- Joined

- Mar 24, 2005

- Location

- Stanley, NC

I'm 25-30min from 77/485Do you know of anyone convenient to I77 between north Charlotte and Elkin?