On the new axle I’m building for my buggy I’m using a PSC ram and clamps that capture end of the ram so that it doesn’t try to move in the clamps.

View attachment 445714

The ram I’m using is the XR series ram that has slots machined in the body for the normal clamps from PSC. With the captured clamps I’m only using two outer clamps. The clamps are wider than the outer grooves so the end cap is not all the way against the clamp, there’s a 3/16” gap.

View attachment 445715

View attachment 445716

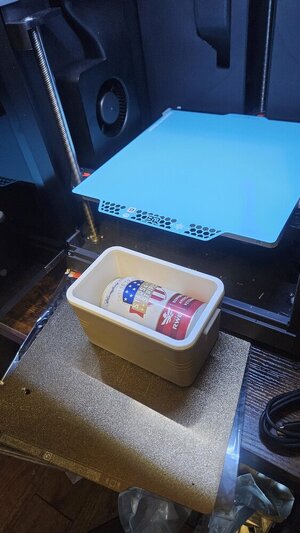

I’d like to have something to fill that gap between the end cap and the clamp. In theory it’s not going to have any force against it because the groove in the ram is against the clamp and it can’t move. I was planning on just making some “washers” out of aluminum but was wondering if it wasn’t some that could be 3D printed. In my mind would be just fine.

Would any of you guys be interested in printing a pair of them for me? I’ll gladly pay for time, material, and shipping. I need two “washers”, 2.875”OD X 2”ID X 3/16” thick.

. Was printing a 2a lower that was around 15hrs. Went to sleep with it rolling right along around 60% done and woke up to a frozen printer/touchscreen and an error message of "Hotend NTC Abnormal". Printer will power up/down but always displays the message. Took the print head apart and determined that the control board in the head is bad. Ordered a new one through Anycubic at $30 and now I'm waiting on shipping.

. Was printing a 2a lower that was around 15hrs. Went to sleep with it rolling right along around 60% done and woke up to a frozen printer/touchscreen and an error message of "Hotend NTC Abnormal". Printer will power up/down but always displays the message. Took the print head apart and determined that the control board in the head is bad. Ordered a new one through Anycubic at $30 and now I'm waiting on shipping.