Mac5005

Well-Known Member

- Joined

- Oct 19, 2005

- Location

- Rocky Mount

So, Ive searched and read almost all the threads on here, and on pirate about what number to shoot for with the 4 link calculator. I've been playing around with it, and think i am somewhere close to haveing it "right" but it seems like i can't get it perfect. The numbers I have entered now are a little off from the measurements i got from the back of the jeep, but they are still within range of what i can do. I have not welded anything yet, nor made any brackets yet, since I am trying to get all the geometry friguered out ahead of time.

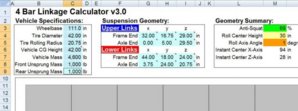

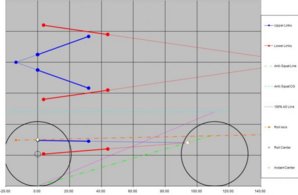

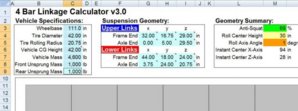

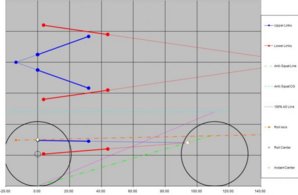

heres what i'm looking at.

at ride height:

69% antisquat and 1.297 deg. Roll axis

At full bump:

69% a/s, and -7.119 roll axis

heres where it goes haywire and the part that bothers me

at full droop (w/ 18" travel)

104% a/s, and 17.627 degs roll axis

at full droop (w/ 16" travel)

85% a/s, 15 deg roll axis

at full droop( w/ 14" travel)

58% a/s and 13.555 degs roll axis

All of this travel is based off 6" compression, and the difference in travel, is only a difference in droop.

So do i sacrifice the travel to keep the numbers sane, or keep working to the 4 link to tweak the geometry better. I feel like the geometry needs to be better so that the roll axis stays close to the same thing throughout the suspension cycle.

What do you guys think.

Here is a screen shot of the measurements, and of the geometry.

Also, What do you guys think of having the lower links mounted to the "front" of the tubes instead of the bottom. To me, It seems like what i am giving up in strength, i am gaining in geometry. It worked out better to have them on the front, but i fear they reall should be on the bottom.

discuss:

heres what i'm looking at.

at ride height:

69% antisquat and 1.297 deg. Roll axis

At full bump:

69% a/s, and -7.119 roll axis

heres where it goes haywire and the part that bothers me

at full droop (w/ 18" travel)

104% a/s, and 17.627 degs roll axis

at full droop (w/ 16" travel)

85% a/s, 15 deg roll axis

at full droop( w/ 14" travel)

58% a/s and 13.555 degs roll axis

All of this travel is based off 6" compression, and the difference in travel, is only a difference in droop.

So do i sacrifice the travel to keep the numbers sane, or keep working to the 4 link to tweak the geometry better. I feel like the geometry needs to be better so that the roll axis stays close to the same thing throughout the suspension cycle.

What do you guys think.

Here is a screen shot of the measurements, and of the geometry.

Also, What do you guys think of having the lower links mounted to the "front" of the tubes instead of the bottom. To me, It seems like what i am giving up in strength, i am gaining in geometry. It worked out better to have them on the front, but i fear they reall should be on the bottom.

discuss: