- Joined

- Mar 24, 2005

- Location

- Stokesdale-Greensboro

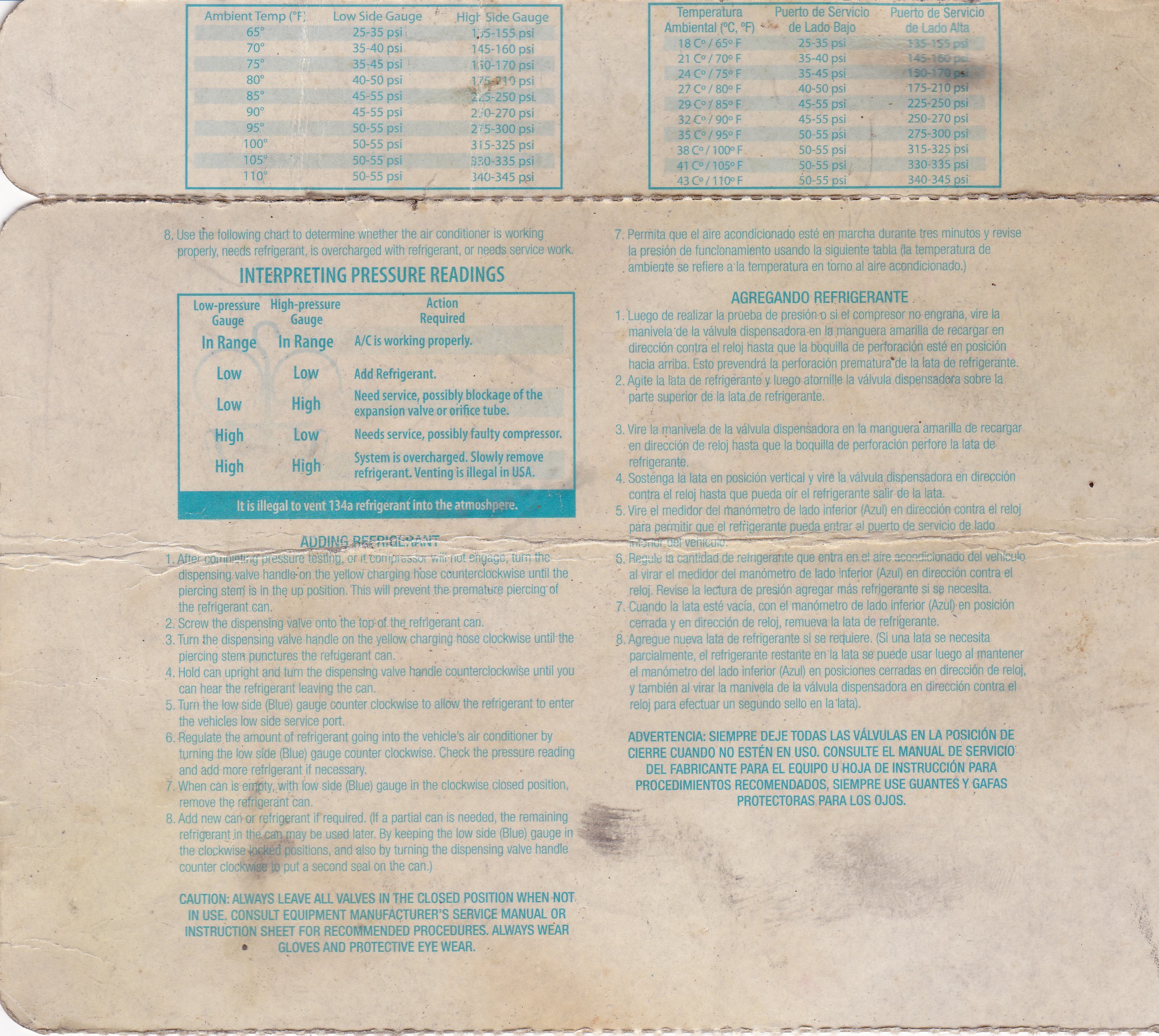

2001 5.3l suburban...ac was blowing hot, ac compressor was not spinning. So I got a hose with gauge AC Pro Recharge Hose with Gauge ACP-400: Advance Auto Parts and 3 12oz cans of R134a. I was hoping it was just low, but it appears something more could be wrong. With the engine running and AC maxed, I started adding refrigerant. In the 6 months I've owned the burb, I have never heard the comp kick in, so I was excited when it kicked on. But then, it started cycling off/on, and the gauge was near the max line, 50psi or so. I don't want to keep adding more, what else should I do? The compressor will run for 2-3 seconds, then shutoff for about 20 seconds. When it kicks on, the gauge drops to zero...maybe I should be pumping more in during these couple seconds?