hunterdan

Well-Known Member

- Joined

- Apr 13, 2009

- Location

- Morganton,NC

Hey all,

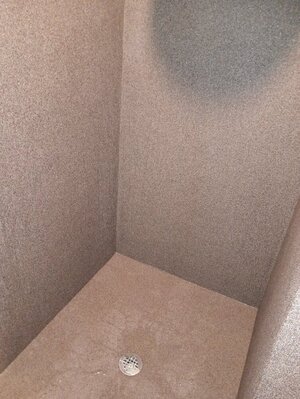

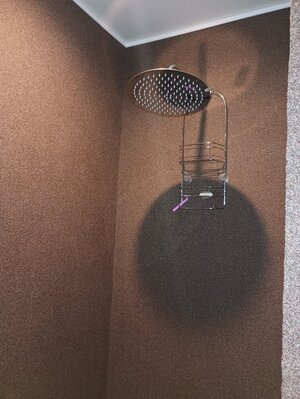

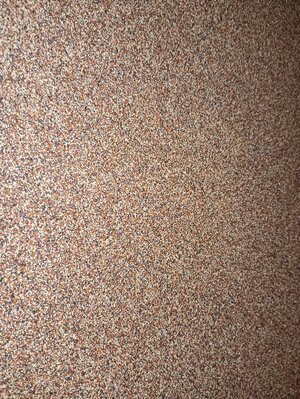

I'm wanting to finish our upstairs bathroom. I already have backer board on walls and concrete floor lined and poured. We were planning on doing tile but We are leaning towards corrugated steel walls and one of those epoxy type floor coverings. The reason I want to do corrugated walls is that's what we used for ceilings and it hasn't rusted or discolored on outside shower after 2 years. My main concern is can I use the epoxy on the Hardie board? Hardie board has kind of a waffle pattern on it. I'm thinking maybe use a thinset mortar on the Hardie board to keep whichever coating we use from just following the pattern of the Hardie board. The only areas that will have coating on Hardie board are the bottom foot of shower walls, step in and right /left side of entry. What say y'all? Looking forward to any suggestions.

Thanks, Daniel

I'm wanting to finish our upstairs bathroom. I already have backer board on walls and concrete floor lined and poured. We were planning on doing tile but We are leaning towards corrugated steel walls and one of those epoxy type floor coverings. The reason I want to do corrugated walls is that's what we used for ceilings and it hasn't rusted or discolored on outside shower after 2 years. My main concern is can I use the epoxy on the Hardie board? Hardie board has kind of a waffle pattern on it. I'm thinking maybe use a thinset mortar on the Hardie board to keep whichever coating we use from just following the pattern of the Hardie board. The only areas that will have coating on Hardie board are the bottom foot of shower walls, step in and right /left side of entry. What say y'all? Looking forward to any suggestions.

Thanks, Daniel

Attachments

Last edited: