a_kelley

mechanical fixer

- Joined

- Jan 26, 2010

- Location

- Rutherfordton

This came into my shop as a Toyota pickup. Original power train and drive train was removed.

In went a Chevy 350, nv3500, np208, d44 front & 12 bolt rear.

For the brakes, everything on the axles is Chevy, so going to run the Toyota booster with an adapter from sky off road with the Chevy master & prop valve & rubber lines. Is there any reason to use 1/4" line instead of 3/16" to feed the rear drums?

Now .... all the details to make it work.

Steering & front axle - custom pitman arm, reused Chevy push-pull linkage, need to notch in a pipe for the rear spring bushing. It'll be close to the body mount but at the bottom of the frame, so no interference. Running bastard Chevy front leaves, as this truck was originally IFS. Need to address the shock mounts as well (intending to use Chevy front shocks unless the Toyota ones will provide enough damping for the extra weight.. I'm sure there's a valving difference.)

Chevy parts for the clutch, didn't have a dust cover, so out came the plasma cutter after some CAD(cardboard aided design) work

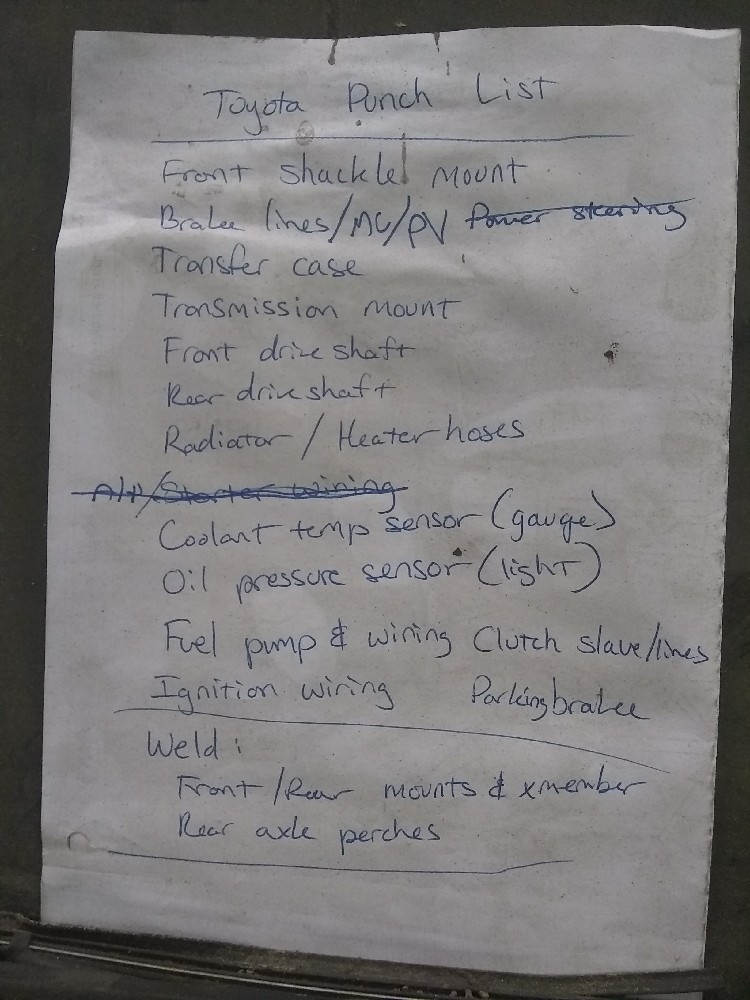

And my punch list.

In went a Chevy 350, nv3500, np208, d44 front & 12 bolt rear.

For the brakes, everything on the axles is Chevy, so going to run the Toyota booster with an adapter from sky off road with the Chevy master & prop valve & rubber lines. Is there any reason to use 1/4" line instead of 3/16" to feed the rear drums?

Now .... all the details to make it work.

Steering & front axle - custom pitman arm, reused Chevy push-pull linkage, need to notch in a pipe for the rear spring bushing. It'll be close to the body mount but at the bottom of the frame, so no interference. Running bastard Chevy front leaves, as this truck was originally IFS. Need to address the shock mounts as well (intending to use Chevy front shocks unless the Toyota ones will provide enough damping for the extra weight.. I'm sure there's a valving difference.)

Chevy parts for the clutch, didn't have a dust cover, so out came the plasma cutter after some CAD(cardboard aided design) work

And my punch list.

Last edited:

Hell yeah.

Hell yeah.