GubNi

8 lug disc brakes?

- Joined

- Mar 20, 2005

- Location

- Jonesborough, TN

On black Friday I drive 15 hours to Tulsa OK and bought this buggy. It's a race ready rig and I hope to compete in it. I don't expect to win often, but I think I can win on occasion. I have been 4-wheeling since Tellico was open and have always enjoyed the extreme part of pushing my machine to make an obstacle. My day job has my emotions fairly dulled so 4-wheeling is the one thing that gets me excited.

Current Specs:

14 bolt front with solid outters and RCV shafts

6.0 LQ9 motor with LS6 heads and intake

TH400

Atlas 3.0

14b rear

Here's my current to do list. Any comments are welcome as I learn a lot from other peoples tech.

Changes:

1. Lower the radiator - Due to overheating the previous owner raised the radiator almost to the top of the cage. That didn't fix it so he put better fans on. That did fix the overheating, but never lowered the radiator.

2. Change fan and radiator style trans cooler to 36" finned tube style. I need to to this to have the extra room to move the radiator down. I don't think the fan style is needed and if so I will relocate it somewhere else.

3. Install rear view mirror. This is something I add to every rig and I really enjoy having. When on the trail I always try to keep the guy behind me in sight.

4. Raise the roof. I'm 6'2" and right now if I straighten my neck I hit the roof. The seats are at 25* and I prefer 35*. Changing this will make less that I have to raise the roof, but still I will have to cut some tube and splice in a domed roof. I prefer a domed roof as I feel it's safer anyway.

5. Change alternator brackets. It has LSS brackets to move the alternator out more for front air filter. This resulted in some goofy plumbing fittings being used on the radiator to chassis hose. The intake has been turned around the the filter is now in the cab. I am going to get some different brackets to move the alternator back and clean up the look there. Possible bracket kit --link

6. Trim and paint hood skins. There are two hood skins that are not installed. They are black and need to be painted white and then trimmed as needed to go around the PSC reservoir.

7. Swap out stickies for boggers. I plan to keep the stickies, but I am a big fan of cut boggers and I have a new set of skinny 44's that I want to put on it. I'll try both, but most places I go have more loose soil than dry rocks.

8. Catch can for motor - I had a friend tell me these motors need a catch can for PVC oil if you run them hard. I need to look into it more.

9. Window nets - For racing I need window nets.

10. It has stock chevy front brakes. Of course since I am a brake guy www.lugnut4x4.com I am going to put a 3/4 ton conversion on it and lighten it by 41lbs.

11. Install passenger handle and foot hole in passenger side skin.

12. Figure out storage. Most of the time I will use it for trail riding and need storage for lunch, snacks, coats, and etc. I can rework the console above the rear drive shaft for some room and then maybe above the gas tank on each side.

13. Rewire tail lights. Right now they only come on with rock lights. I think they should come on with headlights and hook up to brake also.

14. Redo fuel vent. For racing there is a specific route for the fuel vent so I have to change that.

15. It seems to lean a little to one side. I need to check pressure in all 4 corners.

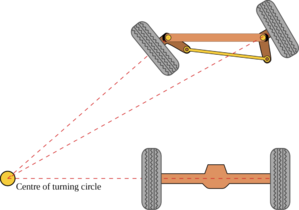

16. The turning radius is awful. It's 120" WB which is longer than I am used to, but still this is way off. I looked at it and the front axle is tilted 5* forward for no real reason. I should be able to adjust the links to fix that. There may be more work needed to get the turning radius where I want.

Current Specs:

14 bolt front with solid outters and RCV shafts

6.0 LQ9 motor with LS6 heads and intake

TH400

Atlas 3.0

14b rear

Here's my current to do list. Any comments are welcome as I learn a lot from other peoples tech.

Changes:

1. Lower the radiator - Due to overheating the previous owner raised the radiator almost to the top of the cage. That didn't fix it so he put better fans on. That did fix the overheating, but never lowered the radiator.

2. Change fan and radiator style trans cooler to 36" finned tube style. I need to to this to have the extra room to move the radiator down. I don't think the fan style is needed and if so I will relocate it somewhere else.

3. Install rear view mirror. This is something I add to every rig and I really enjoy having. When on the trail I always try to keep the guy behind me in sight.

4. Raise the roof. I'm 6'2" and right now if I straighten my neck I hit the roof. The seats are at 25* and I prefer 35*. Changing this will make less that I have to raise the roof, but still I will have to cut some tube and splice in a domed roof. I prefer a domed roof as I feel it's safer anyway.

5. Change alternator brackets. It has LSS brackets to move the alternator out more for front air filter. This resulted in some goofy plumbing fittings being used on the radiator to chassis hose. The intake has been turned around the the filter is now in the cab. I am going to get some different brackets to move the alternator back and clean up the look there. Possible bracket kit --link

6. Trim and paint hood skins. There are two hood skins that are not installed. They are black and need to be painted white and then trimmed as needed to go around the PSC reservoir.

7. Swap out stickies for boggers. I plan to keep the stickies, but I am a big fan of cut boggers and I have a new set of skinny 44's that I want to put on it. I'll try both, but most places I go have more loose soil than dry rocks.

8. Catch can for motor - I had a friend tell me these motors need a catch can for PVC oil if you run them hard. I need to look into it more.

9. Window nets - For racing I need window nets.

10. It has stock chevy front brakes. Of course since I am a brake guy www.lugnut4x4.com I am going to put a 3/4 ton conversion on it and lighten it by 41lbs.

11. Install passenger handle and foot hole in passenger side skin.

12. Figure out storage. Most of the time I will use it for trail riding and need storage for lunch, snacks, coats, and etc. I can rework the console above the rear drive shaft for some room and then maybe above the gas tank on each side.

13. Rewire tail lights. Right now they only come on with rock lights. I think they should come on with headlights and hook up to brake also.

14. Redo fuel vent. For racing there is a specific route for the fuel vent so I have to change that.

15. It seems to lean a little to one side. I need to check pressure in all 4 corners.

16. The turning radius is awful. It's 120" WB which is longer than I am used to, but still this is way off. I looked at it and the front axle is tilted 5* forward for no real reason. I should be able to adjust the links to fix that. There may be more work needed to get the turning radius where I want.

Last edited: