skyhighZJ

Gov retirement < needs to live

- Joined

- May 31, 2012

- Location

- Aberdeen, NC.

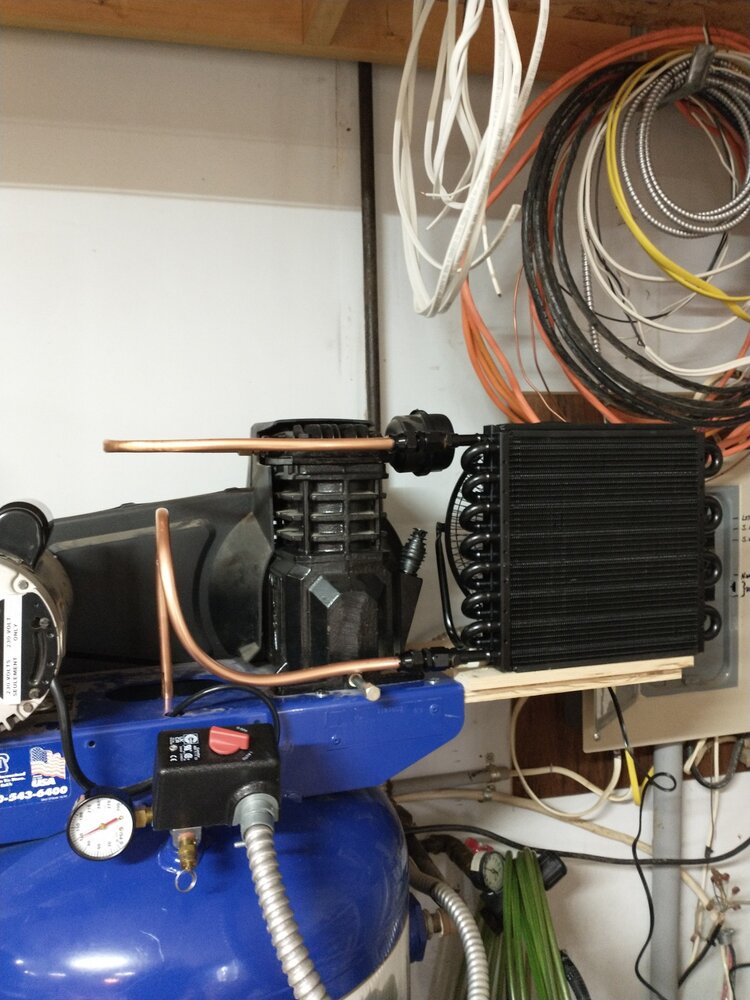

My dad added an “aftercooler” on his upright air compressor to help cool the air prior to entering the tank. Now that he is actually putting it to work doing some body work on his ‘55 he is noticing the compressor getting hot and shutting down earlier than it previously had. He has had this setup about 20yrs and never an issue. Plenty of juice to the motor and has been religiously drained. He is in Northern Michigan so humidistat isn’t really and issue but the tank has been drained just the same. This has seemed to be an issue since he ran the after cooler. The pipe in the cooler is the same diameter as the original size from the compressor to tank so I’m not thinking a restriction issue. Any help would be great. He likes the concept of cooler air entering, thus, leaving the tank. But, not cool that it’s cutting out due to thermal issues with the compressor/ motor. I’m sure it’s something simple but what am I missing.