Tacoma747

Well-Known Member

- Joined

- Mar 20, 2005

- Location

- Winston-Salem

I recently bought a 2005 f-350 that had a 24v cummins swapped into it, I have been addressing some issues with it and just finished building a fuel filter setup for it (to make use of a large quantity of Cummins brand filters I have on hand).

The filter bases use 12mm fittings, which turns out is the same size as the banjo bolt on the injector pump. I got to thinking about flow restriction after seeing the small ID of some of the fittings I was using (6 JIC), but the factory fuel line is 5/16", and a 5/16" Barb fitting is not that much larger than the 6 JIC, but regardless I ordered new fittings online to change everything to 5/16 Barb fittings (which will get rid of the 6 JIC adapters)

I see after doing some research about people upgrading to larger lines, even found a suggested banjo bolt that goes at the injector pump that has a .187 opening instead of a .130 opening. So for that matter it seems like a waste to upgrade fittings anywhere else if the injector pump fitting is the smallest diameter fitting. Am I over thinking this?

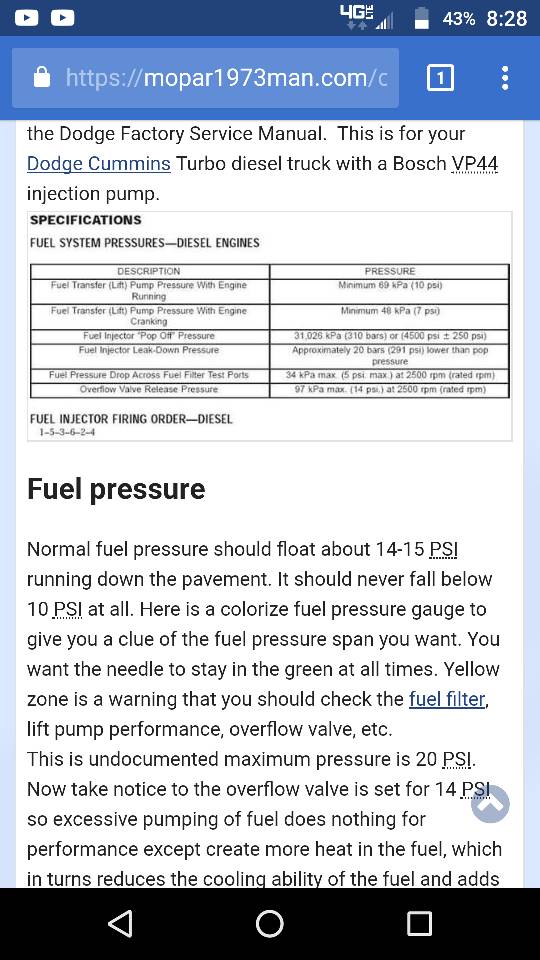

The truck has some sort of in tank fuel pump, not sure what it is. I put a gauge on top of the 2nd filter (on the outlet) and it reads 10psi at idle, drops to about 8psi at WOT (no load). Not sure what the pressures are while driving. Finding mixed opinions online if that is too low or not.

Opinions?

The filter bases use 12mm fittings, which turns out is the same size as the banjo bolt on the injector pump. I got to thinking about flow restriction after seeing the small ID of some of the fittings I was using (6 JIC), but the factory fuel line is 5/16", and a 5/16" Barb fitting is not that much larger than the 6 JIC, but regardless I ordered new fittings online to change everything to 5/16 Barb fittings (which will get rid of the 6 JIC adapters)

I see after doing some research about people upgrading to larger lines, even found a suggested banjo bolt that goes at the injector pump that has a .187 opening instead of a .130 opening. So for that matter it seems like a waste to upgrade fittings anywhere else if the injector pump fitting is the smallest diameter fitting. Am I over thinking this?

The truck has some sort of in tank fuel pump, not sure what it is. I put a gauge on top of the 2nd filter (on the outlet) and it reads 10psi at idle, drops to about 8psi at WOT (no load). Not sure what the pressures are while driving. Finding mixed opinions online if that is too low or not.

Opinions?