Long story short for now...ask questions and I'll try to answer them.

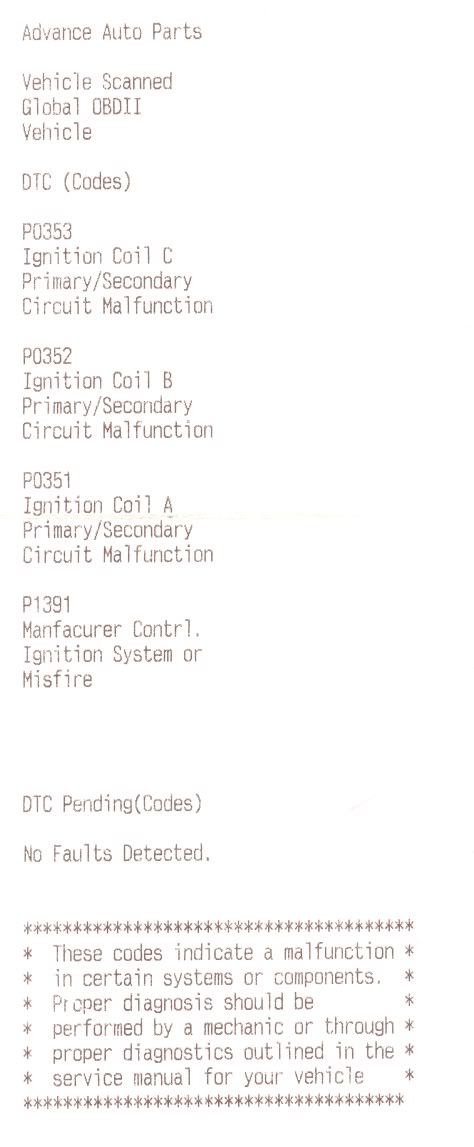

Fuel cell connected wrong, had the return line hooked up to the wrong connection on the fuel cell...caused a large amount of pressure buildup in the fuel cell. No where for the pressure to go so it decided to escape out of the front of the vehicle through the fuel line going towards the fuel rail. A good bit of fuel on the ground under the jeep...vehicle studderd and hesitated, sometimes completely cutting out at low RPM's both before and after the spillage. I've since moved the return hose to another (now thought to be the correct connection) on the fuel cell. Vehicle through out the codes posted.

What's going on and what should I expect to see when I pull the coil pack and plugs?

This post is to get some ideas before I get into it. I'll know more when I pull the spark plugs-- I know that.

Help out if you can.

Thanks,

Staton

Fuel cell connected wrong, had the return line hooked up to the wrong connection on the fuel cell...caused a large amount of pressure buildup in the fuel cell. No where for the pressure to go so it decided to escape out of the front of the vehicle through the fuel line going towards the fuel rail. A good bit of fuel on the ground under the jeep...vehicle studderd and hesitated, sometimes completely cutting out at low RPM's both before and after the spillage. I've since moved the return hose to another (now thought to be the correct connection) on the fuel cell. Vehicle through out the codes posted.

What's going on and what should I expect to see when I pull the coil pack and plugs?

This post is to get some ideas before I get into it. I'll know more when I pull the spark plugs-- I know that.

Help out if you can.

Thanks,

Staton

)

)