Georgia Mike

Well-Known Member

- Joined

- Jul 19, 2008

- Location

- flowery branch, GA

Hey guys, most of my previous experience with builds has been upgraded stock type replacements (bolt-ons, if you will) and I'm making the jump to tons in a ZJ. I see so many different options when it comes to high steer setups, and thankfully these days a "kit" is just a click away, so I don't have to start completely from scratch. But what kit do I need?

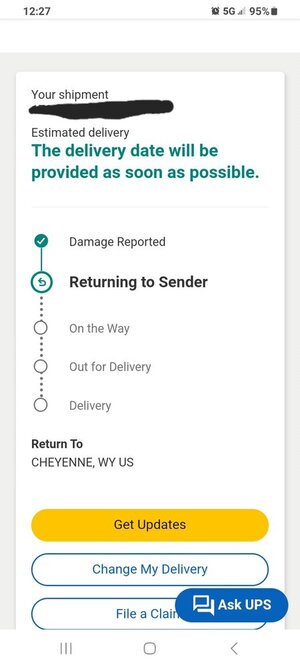

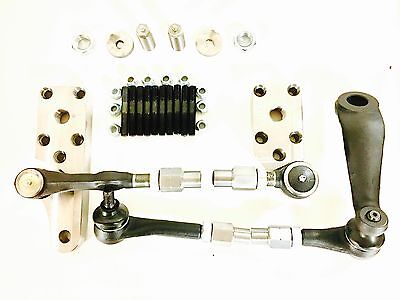

I've been looking at this kit:

And also this one:

Now I understand what actually makes the two kits different parts-wise, my question is which one would be a better fit for my application?

My setup will be:

'78 Ford Dana 60

Stock steering box (tapped)

TnT truss with track bar mount for high steer

Gusseted stock knuckles

Hopefully hydro assist

Stock-ish suspension design (long arms with track bar)

Most likely zero to very minimal street driving (building it as a dedicated trail queen)

Can anyone explain to me why I should choose one style over the other? My gut tells me to go with the full crossover and not the Y-link, but what do I know. That's why I'm asking you guys that know way more than me

I've been looking at this kit:

DANA 60 HIGH STEER CROSOVER STEERING KIT FOR ALL DANA 60 APP THICK ARMS STUDS HD | eBay

Dana 60 High Steer for ALL Dana 60 Application, NO DOM Tubes. 10 - 1/2" Fine Threaded Studs. (Arms are 5 Hole pattern to suit Reid and any other Knuckle). Kit is without DOM tubing, buy local and save.

www.ebay.com

And also this one:

DANA 60 HIGH STEER CROSOVER STEERING KIT FOR ALL DANA 60 APP THICK ARMS STUDS HD | eBay

Dana 60 High Steer for ALL Dana 60 Application, NO DOM Tubes. 10 - 1/2" Fine Threaded Studs. (Arms are 5 Hole pattern to suit Reid and any other Knuckle). Kit is without DOM tubing, buy local and save.

www.ebay.com

Now I understand what actually makes the two kits different parts-wise, my question is which one would be a better fit for my application?

My setup will be:

'78 Ford Dana 60

Stock steering box (tapped)

TnT truss with track bar mount for high steer

Gusseted stock knuckles

Hopefully hydro assist

Stock-ish suspension design (long arms with track bar)

Most likely zero to very minimal street driving (building it as a dedicated trail queen)

Can anyone explain to me why I should choose one style over the other? My gut tells me to go with the full crossover and not the Y-link, but what do I know. That's why I'm asking you guys that know way more than me