QCB_Preacher

New Member

- Joined

- Feb 25, 2009

- Location

- Charlotte, NC

I know I can't post pictures yet, but you can click the links for the photos.

First, let me say that I am certifiably insane, and that anyone else who tries this is also insane. It is easier to break out the credit card than it is to break your a** doing this stuff yourself, but I am in to pain so.... with that in mind, read on!

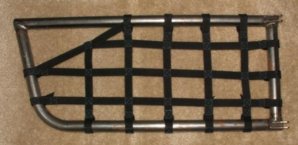

After seeing some of the cool cargo nets you can get online, and seeing the premium prices they get for those nets, I couldn't help but think that I could make my own.

This is my odyssey.

First comes the design. I wanted a net that covers the sides, the top and the back, but the back has to be able to open up so you can load and unload the cargo area. Seems easy enough.

Next, I had to source materials and, in keeping with the idea of doing it myself, I wanted to keep costs down.

After surfing around and comparing prices on numerous websites, I found some polypro webbing at a price I liked. I chose polypro over nylon becuase it is waterproof and mold resistant while Nylon is neither. Should last longer when exposed to the elements. The webbing I chose has a 550lb tensile strength which should be more than enough when made into a net.

100yds of Polypro webbing, 1" wide = $16.99 (Red was $4 cheaper than black)

Now, I have to have a way to attach the webbing to the roll cage and keep it taught so that it isn't flapping or coming loose at 70mph. I chose to use friction buckles attached at multiple spots.

50 friction buckles = $7.99

I also needed a way to open the rear of the net to load so I chose quick release buckles.

10 QR Buckles = $7.99

Shipping for all of the above = $5.50

Last element will be a sewing maching capable of sewing together 2 or 3 layers of this Polypro webbing, and thread capable of withstanding the stress. To that end, I haunted my local fabric place and found upholstery thread and bought a spool.

Upholstery Thread = $4.99

Total cost (So Far) is $53.46

Now for the fun part.

______________________

Ok, so I laid out the basic lines and sewed the corners.

More measuring and began laying out the grid

First, let me say that I am certifiably insane, and that anyone else who tries this is also insane. It is easier to break out the credit card than it is to break your a** doing this stuff yourself, but I am in to pain so.... with that in mind, read on!

After seeing some of the cool cargo nets you can get online, and seeing the premium prices they get for those nets, I couldn't help but think that I could make my own.

This is my odyssey.

First comes the design. I wanted a net that covers the sides, the top and the back, but the back has to be able to open up so you can load and unload the cargo area. Seems easy enough.

Next, I had to source materials and, in keeping with the idea of doing it myself, I wanted to keep costs down.

After surfing around and comparing prices on numerous websites, I found some polypro webbing at a price I liked. I chose polypro over nylon becuase it is waterproof and mold resistant while Nylon is neither. Should last longer when exposed to the elements. The webbing I chose has a 550lb tensile strength which should be more than enough when made into a net.

100yds of Polypro webbing, 1" wide = $16.99 (Red was $4 cheaper than black)

Now, I have to have a way to attach the webbing to the roll cage and keep it taught so that it isn't flapping or coming loose at 70mph. I chose to use friction buckles attached at multiple spots.

50 friction buckles = $7.99

I also needed a way to open the rear of the net to load so I chose quick release buckles.

10 QR Buckles = $7.99

Shipping for all of the above = $5.50

Last element will be a sewing maching capable of sewing together 2 or 3 layers of this Polypro webbing, and thread capable of withstanding the stress. To that end, I haunted my local fabric place and found upholstery thread and bought a spool.

Upholstery Thread = $4.99

Total cost (So Far) is $53.46

Now for the fun part.

______________________

Ok, so I laid out the basic lines and sewed the corners.

More measuring and began laying out the grid