Tradarcher

Well-Known Member

- Joined

- Mar 20, 2005

- Location

- Creedmoor, NC

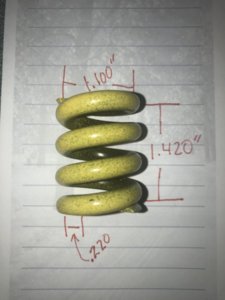

Here's my dilemma. I have a high dollar video tripod head that has a compression spring in it that is interchangeable depending on the weight of the camera. Right now it has what I believe is the heaviest spring they make for 20+ pound cameras. I'll never find a lighter spring (i've tried) so I will have to make one. The image below shows the dimensions. It looks similar to a harley fork spring. I lowered a harley front end once and cut off about an inch but I must have thrown what I cut off away so I can't compare it. I am wondering where I might look to get another spring with a lower rate even if it is too long. I can shorten it if necessary.