Mac5005

Well-Known Member

- Joined

- Oct 19, 2005

- Location

- Rocky Mount

Just trying to get some more tech going on, and get some brains working.

Pretty cool tech to me, ymmv.

Ken @BRUISER was kind enough to invite my dad @moldman05 and I and many other out to the lakebed this year to help with pitting and to experience KOH.

Jason scherer won the 4400 class this year and said that fox made some huge changes just before the race that raised his top speed close to 20mph in the desert.

This made everyone wonder what kind of special changes those were.

Talks of Fox’s new live valve system with servo controlled valving, and active suspension control dominated the hearsay.

After thinking about it for a couple days and on the plane ride home, curiosity got the best of me.

I reached out to Jason to ask, what were the changes? I couldn’t stand it, I just had to know.

Thankfully Jason being an awesome dude responded and was open and honest about the changes that were made.

He said larger bypass tubes and a nitrogen valve instead of the spring in the tube. Says it holds the car up longer and takes the hit smoother.

From the pics I have and I was looking for the servos, it didn’t have servos on any bypass tube or c/o resi.

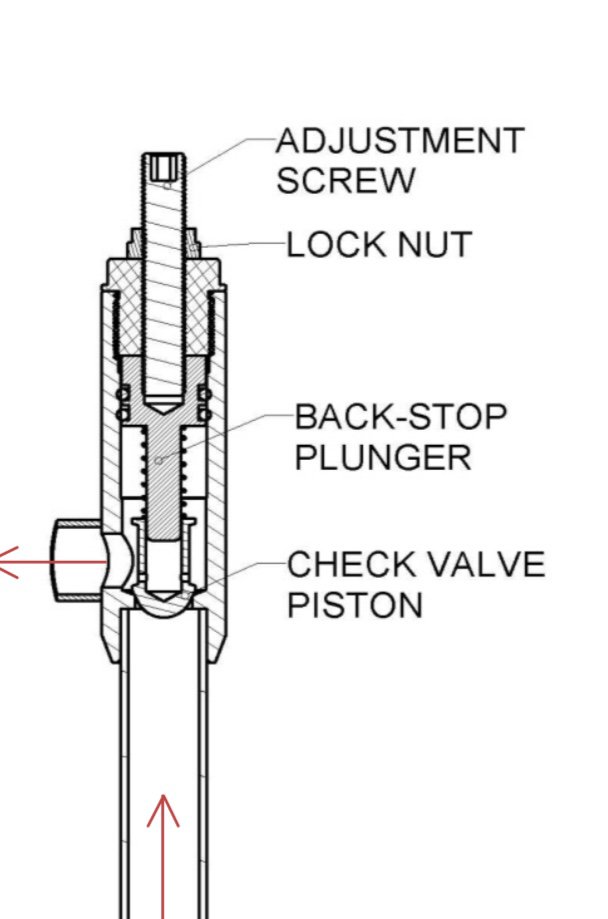

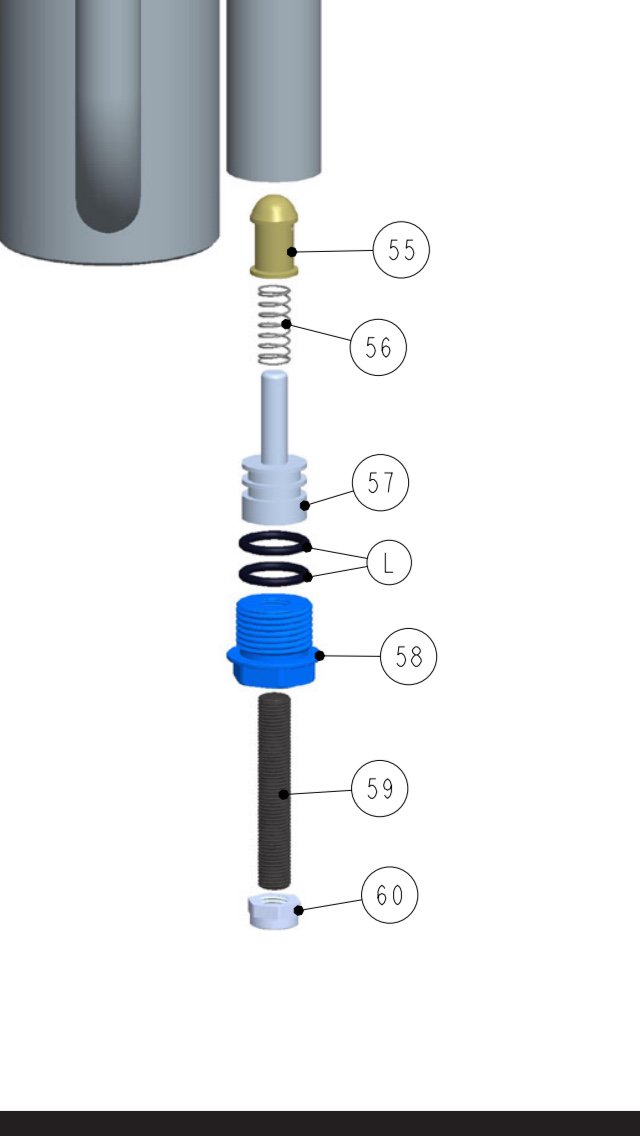

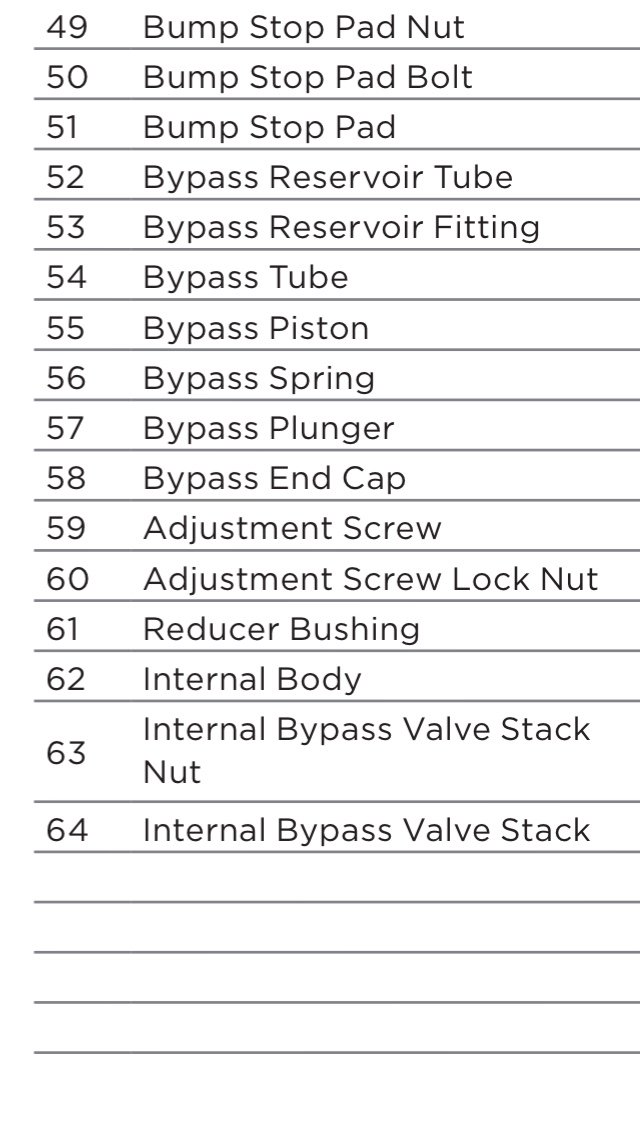

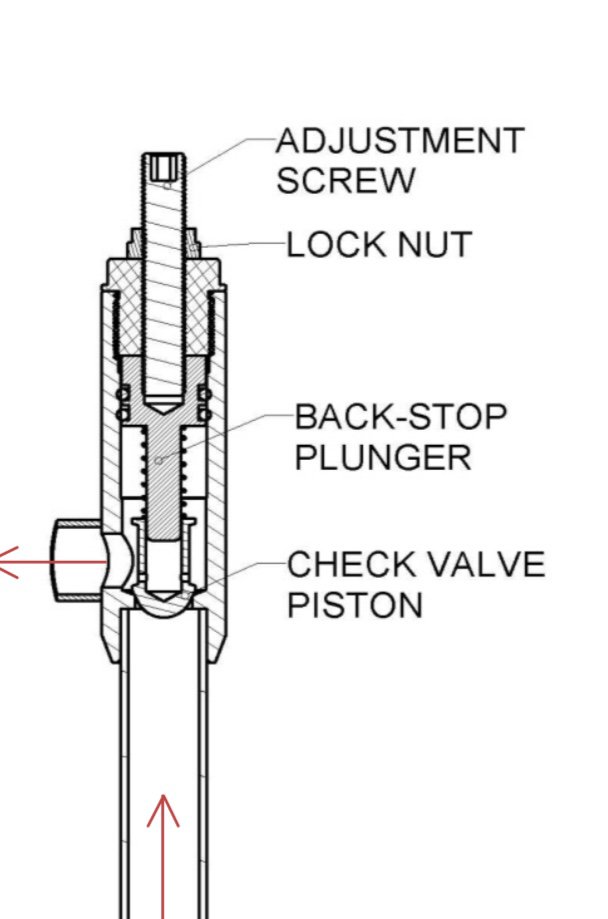

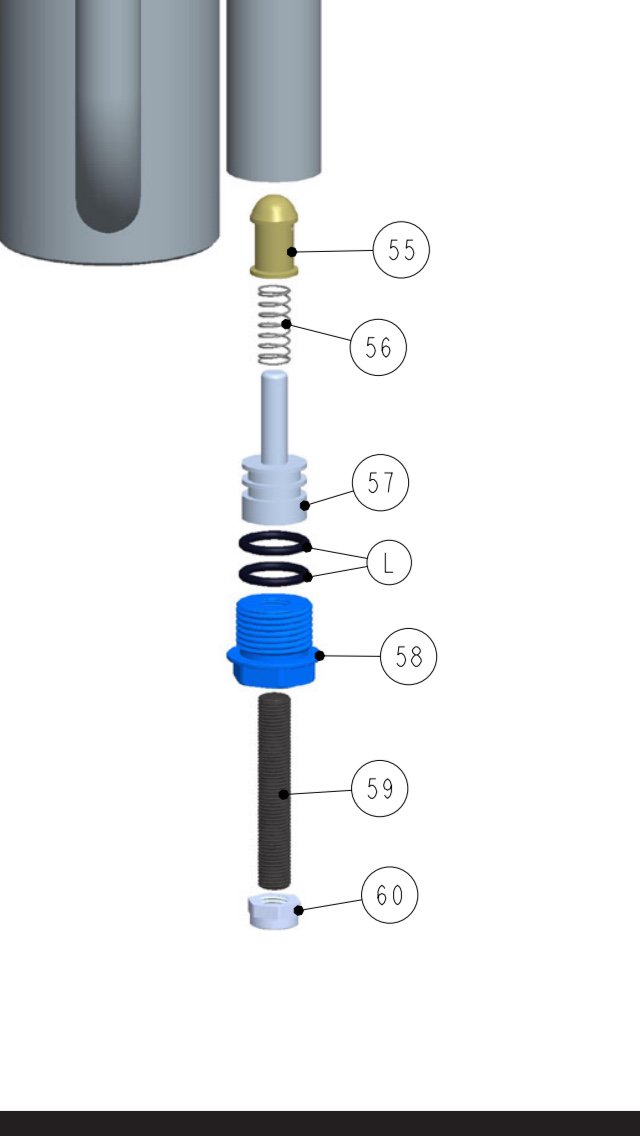

It took me a few hours of thinking and chewing on what he told me, and I went down the google rabbit hole looking for exploded diagrams.

After chewing on this info,

It actually doesn’t look too crazy to remove the spring from the bypass tube, add a few orings to the tube end cap, replace the adjustment bolt with a schrader valve, and use n2 pressure instead of a mechanical spring.

Then can change n2 pressure to adjust the bypass tube(s).

It’s very Interesting thinking about the psi/force differences between the two and the practical real world differences.

So no active suspension on ultra4 stuff, yet. Currently only available in ford raptors and new rzrs. It’s crazy thinking about how the live valve/active suspension systems will change ultra4 when it becomes available and implemented.

Fox has already shown servo adjusters bypasses and now servo adjusted dampening in the reservoir with the new rzr.

Pretty cool tech to me, ymmv.

Ken @BRUISER was kind enough to invite my dad @moldman05 and I and many other out to the lakebed this year to help with pitting and to experience KOH.

Jason scherer won the 4400 class this year and said that fox made some huge changes just before the race that raised his top speed close to 20mph in the desert.

This made everyone wonder what kind of special changes those were.

Talks of Fox’s new live valve system with servo controlled valving, and active suspension control dominated the hearsay.

After thinking about it for a couple days and on the plane ride home, curiosity got the best of me.

I reached out to Jason to ask, what were the changes? I couldn’t stand it, I just had to know.

Thankfully Jason being an awesome dude responded and was open and honest about the changes that were made.

He said larger bypass tubes and a nitrogen valve instead of the spring in the tube. Says it holds the car up longer and takes the hit smoother.

From the pics I have and I was looking for the servos, it didn’t have servos on any bypass tube or c/o resi.

It took me a few hours of thinking and chewing on what he told me, and I went down the google rabbit hole looking for exploded diagrams.

After chewing on this info,

It actually doesn’t look too crazy to remove the spring from the bypass tube, add a few orings to the tube end cap, replace the adjustment bolt with a schrader valve, and use n2 pressure instead of a mechanical spring.

Then can change n2 pressure to adjust the bypass tube(s).

It’s very Interesting thinking about the psi/force differences between the two and the practical real world differences.

So no active suspension on ultra4 stuff, yet. Currently only available in ford raptors and new rzrs. It’s crazy thinking about how the live valve/active suspension systems will change ultra4 when it becomes available and implemented.

Fox has already shown servo adjusters bypasses and now servo adjusted dampening in the reservoir with the new rzr.

Last edited: