Tim C

Wizard

- Joined

- Jan 22, 2007

- Location

- Fayetteville

This isnt on my 4x4 but I figured I'd post up to see if @Jody Treadway or any of the ECGS guys may have seen this. Its on my 67 Ford Fairlane. I've got a vibration/ resonance that starts up around 65 mph and goes away just after 70 mph. It will do this even if you clutch in so the engine rpm drops to idle. It will start making a sound like tsl boggers on pavement at the same time but the frequency and volume of the bogger noise will change even at a steady road speed. Pretty sure its coming from the rear axle area. Read on for more info if you're intrested. LOL

Now for the long story: Unfortunately the car is basically brand new so I can't narrow this down to any particular factor. I'm turning this thing into a cruiser from a drag car. Last year before the hot rod power tour I pulled the drag springs out in the front and lowered the car several inches. I built a new 445 stroker engine last year (390 FE stroked to 4.25") with a roller cam. Pulled the old 390 just after Thanksgiving and got the new one dropped in and running just before Christmas. Only put 60 miles on it. The new engine idles smooth for the cam it has and it revs smooth in neutral. Pretty sure its not the engine.

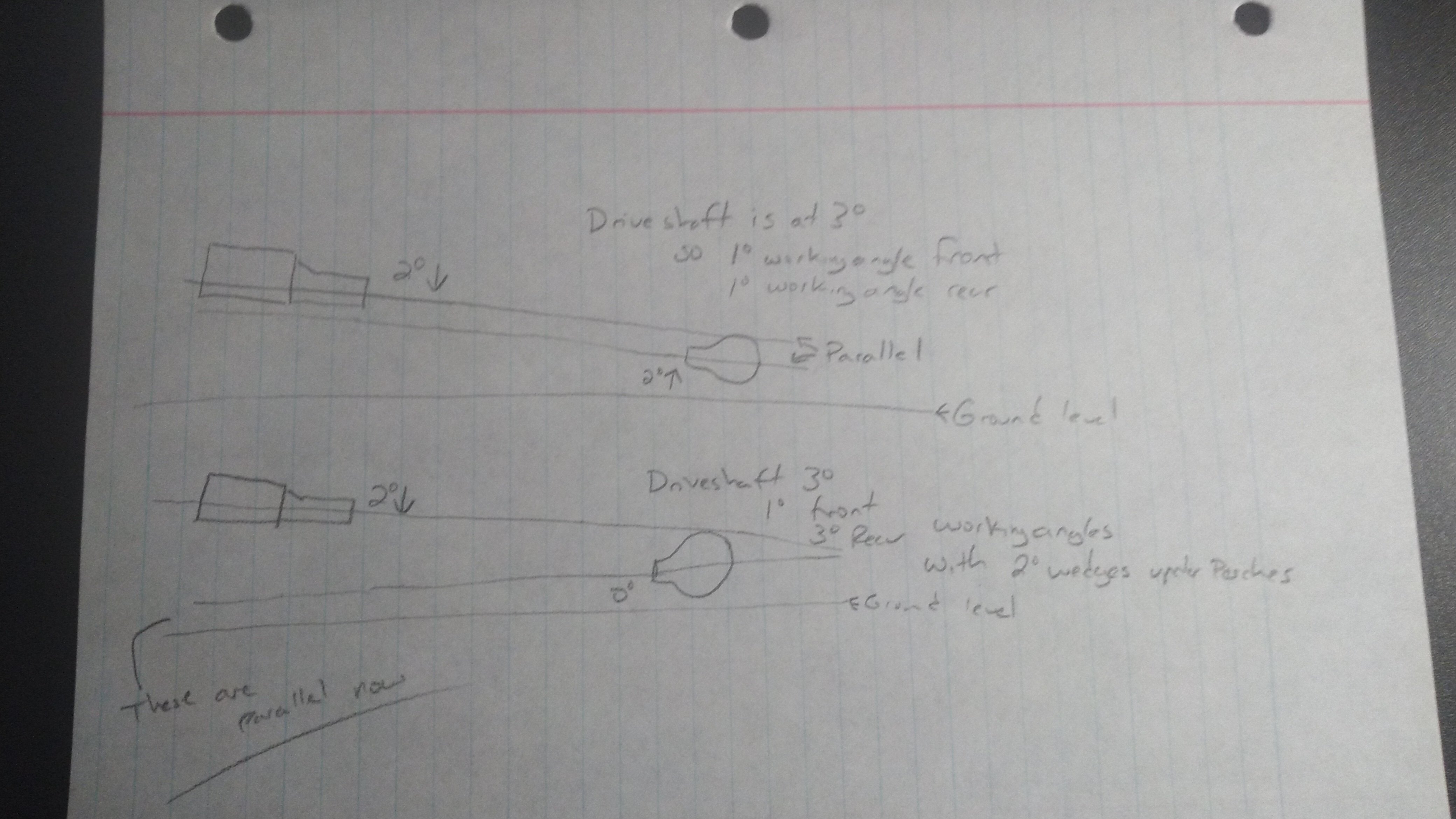

While doing the motor swap, I removed the old collapsed stock eng/trans mounts that had been welded solid with plate around the rubber and replaced with stock motor mounts because the solid mounts made the whole car shake like crazy. The new mounts had the engine and trans sitting higher in the frame (the trans is now closer to the tunnel under the car for example). Because of this my previous slight driveline vibration got much worse. Before it would shake at high speed and get really bad on decel. After the motor swap it got a terrible vibration on acceleration. I narrowed that down to the pinion angle, basically trans output was 2* down, driveshaft 3* down, pinion 2* down so the angles were mismatched and it was "jump roping". Basically 1* on the front joint, 5* at the rear.

To better measure the pinion angle, I pulled the driveshaft at work one day on the drive on alignment lift. On the way home the vibes were much worse and I started smelling gear oil burning. By the time I got home the yoke had welded itself to the output on the trans. I had to beat the driveshaft out of the trans with a 3 lb hammer. The output shaft was blue from the heat. When I put the shaft back in at work it pushed the tailhousing bushing into the transmission so there was no support and the shitty pinion angles let it beat itself to death. Obviously it was on its way out already. I ordered a new 31 spline output for the toploader 4 speed, a new tail housing with bushing, and a rebuild kit and rebuilt my toploader. I also ordered a new aluminum balanced driveshaft from a company out of Texas that a local buddy with a coyote swapped 68 F100 uses for his own trucks as well as customers.

I removed the old homemade unadjustable ladder bars from the car along with the housing floater and put perches back on the 9" after I set the pinion angle at ride height so now the trans is down 2*, axle up 2* so the angles are the same and pointing at one another now with the center lines parallel like they should be. 1* at each end. Made a set of custom traction bars that bolt in where the ladder bars used to be to keep axle hop down.

The car accelerates smooth now all the way up to 90ish so the driveshaft and angles should be good now. I had thought it may be in the tires and the nittos were at the wear bars so today I put a set of P275/60R15 (28x10.5) cooper cobras on the weld draglite wheels and balanced them at work. They run true on the hunter balancer and balanced out well but the vibe is still there. I also swapped the driveshaft 180 degrees at the rear pinion yoke with no change.

I also got a set of 3.70 Richmond gears and a TruTrac for Christmas to replace the 4.11 and spool. Im no expert at setting up gears but I used a pinion depth checker and adjusted from there about .005 to get the pattern looking good. I do have a slight gear whine at 55 to 60 but I can live with that its barely noticable over the exhaust. The car has 35 spline moser axles and special (expensive) axle bearing since it still uses the small housing ends. I had to buy two bearings after the power tour because the races had cracked and were leaking oil. Supposedly they do that with street driving because the races are so thin. I plan on getting the big bearing ends welded on but I was hoping to wait a little while until the credit card stopped smoking after all the above.

tl;dr

Motor new, Trans new, driveshaft new, rear axle new, tires new vibration at 65/70mph

I dont know whether this particular vibe has always been there or not because the solid mounts and jacked up pinion angles have caused the car to always vibrate since I've owned it. Now that everything else is running smooth, it is very noticable. Im hoping to do the power tour again this year so I'd like to get this figured out since it is right at freeway speeds.

Now for the long story: Unfortunately the car is basically brand new so I can't narrow this down to any particular factor. I'm turning this thing into a cruiser from a drag car. Last year before the hot rod power tour I pulled the drag springs out in the front and lowered the car several inches. I built a new 445 stroker engine last year (390 FE stroked to 4.25") with a roller cam. Pulled the old 390 just after Thanksgiving and got the new one dropped in and running just before Christmas. Only put 60 miles on it. The new engine idles smooth for the cam it has and it revs smooth in neutral. Pretty sure its not the engine.

While doing the motor swap, I removed the old collapsed stock eng/trans mounts that had been welded solid with plate around the rubber and replaced with stock motor mounts because the solid mounts made the whole car shake like crazy. The new mounts had the engine and trans sitting higher in the frame (the trans is now closer to the tunnel under the car for example). Because of this my previous slight driveline vibration got much worse. Before it would shake at high speed and get really bad on decel. After the motor swap it got a terrible vibration on acceleration. I narrowed that down to the pinion angle, basically trans output was 2* down, driveshaft 3* down, pinion 2* down so the angles were mismatched and it was "jump roping". Basically 1* on the front joint, 5* at the rear.

To better measure the pinion angle, I pulled the driveshaft at work one day on the drive on alignment lift. On the way home the vibes were much worse and I started smelling gear oil burning. By the time I got home the yoke had welded itself to the output on the trans. I had to beat the driveshaft out of the trans with a 3 lb hammer. The output shaft was blue from the heat. When I put the shaft back in at work it pushed the tailhousing bushing into the transmission so there was no support and the shitty pinion angles let it beat itself to death. Obviously it was on its way out already. I ordered a new 31 spline output for the toploader 4 speed, a new tail housing with bushing, and a rebuild kit and rebuilt my toploader. I also ordered a new aluminum balanced driveshaft from a company out of Texas that a local buddy with a coyote swapped 68 F100 uses for his own trucks as well as customers.

I removed the old homemade unadjustable ladder bars from the car along with the housing floater and put perches back on the 9" after I set the pinion angle at ride height so now the trans is down 2*, axle up 2* so the angles are the same and pointing at one another now with the center lines parallel like they should be. 1* at each end. Made a set of custom traction bars that bolt in where the ladder bars used to be to keep axle hop down.

The car accelerates smooth now all the way up to 90ish so the driveshaft and angles should be good now. I had thought it may be in the tires and the nittos were at the wear bars so today I put a set of P275/60R15 (28x10.5) cooper cobras on the weld draglite wheels and balanced them at work. They run true on the hunter balancer and balanced out well but the vibe is still there. I also swapped the driveshaft 180 degrees at the rear pinion yoke with no change.

I also got a set of 3.70 Richmond gears and a TruTrac for Christmas to replace the 4.11 and spool. Im no expert at setting up gears but I used a pinion depth checker and adjusted from there about .005 to get the pattern looking good. I do have a slight gear whine at 55 to 60 but I can live with that its barely noticable over the exhaust. The car has 35 spline moser axles and special (expensive) axle bearing since it still uses the small housing ends. I had to buy two bearings after the power tour because the races had cracked and were leaking oil. Supposedly they do that with street driving because the races are so thin. I plan on getting the big bearing ends welded on but I was hoping to wait a little while until the credit card stopped smoking after all the above.

tl;dr

Motor new, Trans new, driveshaft new, rear axle new, tires new vibration at 65/70mph

I dont know whether this particular vibe has always been there or not because the solid mounts and jacked up pinion angles have caused the car to always vibrate since I've owned it. Now that everything else is running smooth, it is very noticable. Im hoping to do the power tour again this year so I'd like to get this figured out since it is right at freeway speeds.