a_kelley

mechanical fixer

- Joined

- Jan 26, 2010

- Location

- Rutherfordton

Plus high dollar bonus functions at the end!!

So you have a crank driven oil pump motor and you want to prime it before you start it, huh?

Well what you need is a pressure pre-oiler.

I'll show you how you can make one for $45 plus tax, today, right now. A pressure lube setup goes for goes for over $100 from what I've seen briefly looking. I didn't really care if I could find one for $35 online, I wanted it today. Well, now you can make one today.

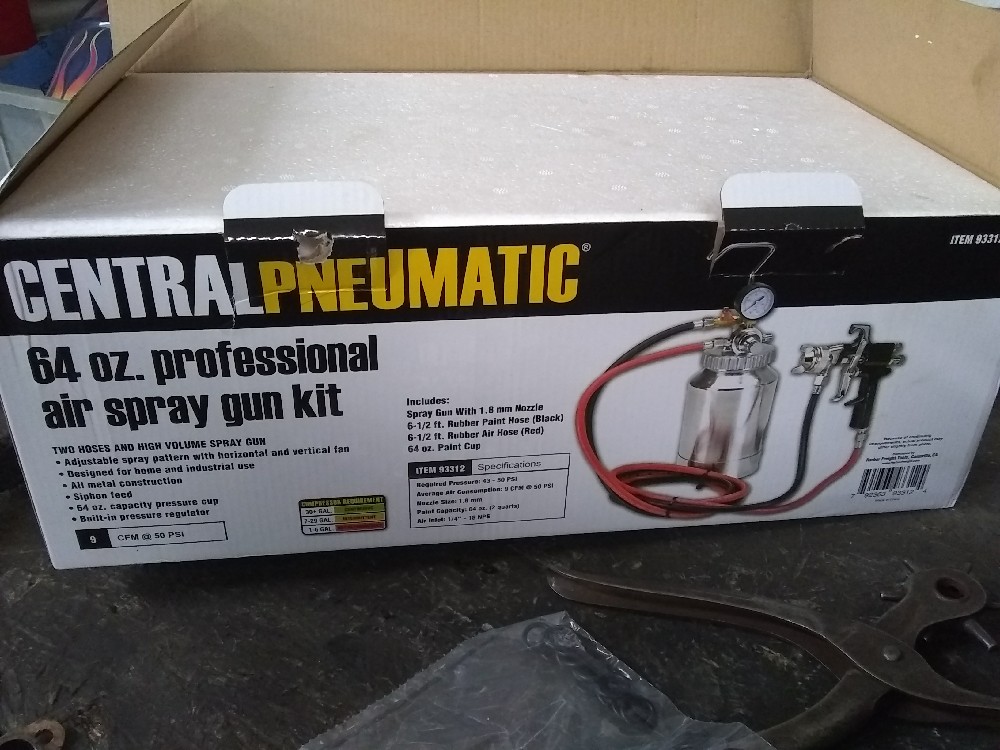

Enter the HFT 64oz spray gun kit.

Ok so now that you bought that, throw the black hose the spray gun in the trash, you wouldn't want to paint with this after it's had oil run through it anyway. Or keep it for a spare for your other sprayer.

Remove the air feed with the gauge. (I've done thrown it out, but there's a nut on the inside of the can and two screws that hold it on.) Scrape the gasket off. Now find a bolt to fit the larger center hole and put a washer on it big enough to cover the two smaller holes. Add ultra grey and install the bolt & washer.

Next, screw the red hose onto the ball valve. Cut the opposite end off or if you're patient, find an adapter fitting to go to your oil gallery plug. I'm not patient enough for all that, especially with Chinese fittings. I simply cut the hose and used a hose barb to pipe thread adapter to attach it to the oil gallery.

You need to drill and tap a hole for a quick connect air fitting. You MUST connect the setup to a regulated air supply. There is a built in pressure relief valve (and bleed valve also) that is retained in the remaining parts on the lid. I put a ball valve in after the QC so that I did not need to disconnect the air line to refill the container, all I need to do is turn off both ball valves, bleed the pressure off with the bleeder & unscrew the jug to fill.

Here's what mine looked like when I was finished.

To use it, fill the container with oil. Turn off both valves, connect the air line to a regulated supply, connect the red hose to the oil gallery, screw the bottle onto the lid, make sure the bleeder is closed, then turn on the air, then turn on the oil. It will then force oil through the motor at whatever pressure you're feeding it. The destructions said max 50 psi, which is just fine for pressure lubing an engine.

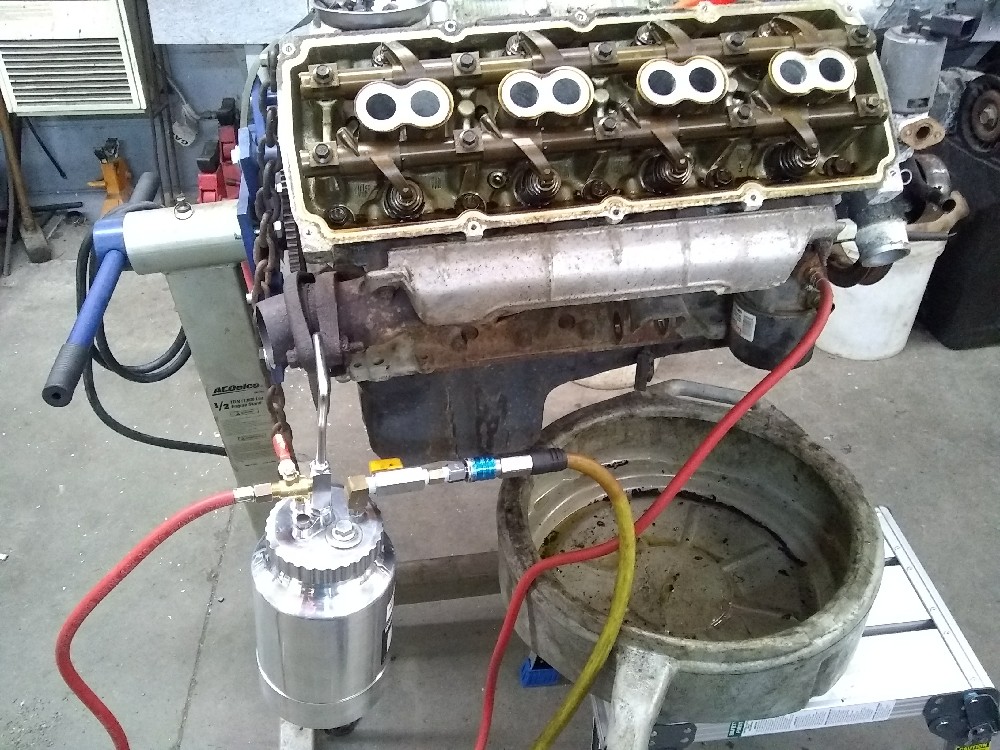

In use:

I don't think they will let me return it though.. but why would I? It's too useful. There are more uses for this thing than just feeding lube to a motor.. you could clean it (or better yet, cut the hose in half, instead of at one end like I did) and after you got the bottle and pipe clean, you can fill it with brake fluid and use it to reverse bleed brakes!!!! I'm so glad I just thought of that. You can also use it combined with a vacuum pump to evacuate fluids. Just it only holds 2 quarts, and if I were to use it to evacuate any fluid, I would add a catch can to save my vacuum pump.

So you have a crank driven oil pump motor and you want to prime it before you start it, huh?

Well what you need is a pressure pre-oiler.

I'll show you how you can make one for $45 plus tax, today, right now. A pressure lube setup goes for goes for over $100 from what I've seen briefly looking. I didn't really care if I could find one for $35 online, I wanted it today. Well, now you can make one today.

Enter the HFT 64oz spray gun kit.

Ok so now that you bought that, throw the black hose the spray gun in the trash, you wouldn't want to paint with this after it's had oil run through it anyway. Or keep it for a spare for your other sprayer.

Remove the air feed with the gauge. (I've done thrown it out, but there's a nut on the inside of the can and two screws that hold it on.) Scrape the gasket off. Now find a bolt to fit the larger center hole and put a washer on it big enough to cover the two smaller holes. Add ultra grey and install the bolt & washer.

Next, screw the red hose onto the ball valve. Cut the opposite end off or if you're patient, find an adapter fitting to go to your oil gallery plug. I'm not patient enough for all that, especially with Chinese fittings. I simply cut the hose and used a hose barb to pipe thread adapter to attach it to the oil gallery.

You need to drill and tap a hole for a quick connect air fitting. You MUST connect the setup to a regulated air supply. There is a built in pressure relief valve (and bleed valve also) that is retained in the remaining parts on the lid. I put a ball valve in after the QC so that I did not need to disconnect the air line to refill the container, all I need to do is turn off both ball valves, bleed the pressure off with the bleeder & unscrew the jug to fill.

Here's what mine looked like when I was finished.

To use it, fill the container with oil. Turn off both valves, connect the air line to a regulated supply, connect the red hose to the oil gallery, screw the bottle onto the lid, make sure the bleeder is closed, then turn on the air, then turn on the oil. It will then force oil through the motor at whatever pressure you're feeding it. The destructions said max 50 psi, which is just fine for pressure lubing an engine.

In use:

I don't think they will let me return it though.. but why would I? It's too useful. There are more uses for this thing than just feeding lube to a motor.. you could clean it (or better yet, cut the hose in half, instead of at one end like I did) and after you got the bottle and pipe clean, you can fill it with brake fluid and use it to reverse bleed brakes!!!! I'm so glad I just thought of that. You can also use it combined with a vacuum pump to evacuate fluids. Just it only holds 2 quarts, and if I were to use it to evacuate any fluid, I would add a catch can to save my vacuum pump.