loki_racer

Well-Known Member

- Joined

- Sep 7, 2005

- Location

- Pittsburgh, PA

I got a Riddler Dana 30 diff cover for my XJ. Painted it up the other day and installed it today.

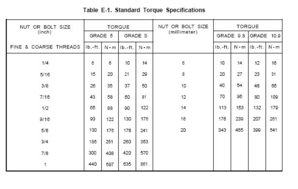

Online it says to torque the bolts to 30-35. I have a torque wrench but have never been school in it's use. I set it to 5 and tightened a bolt to see what happened. The handle gave a small click when I think it reached the 5 ft lbs. I turned it up to 20 and snapped the head off a bolt.

Off to the store to get another bolt and liquor gasket.

30 minutes later after cleaning off the new (ruined gasket) and removing the snapped bolt I start to put it back together. Second bolt in and I snap another bolt.

I'm no mechanic or superman, but I must be doing something wrong here. Any ideas?

Online it says to torque the bolts to 30-35. I have a torque wrench but have never been school in it's use. I set it to 5 and tightened a bolt to see what happened. The handle gave a small click when I think it reached the 5 ft lbs. I turned it up to 20 and snapped the head off a bolt.

Off to the store to get another bolt and liquor gasket.

30 minutes later after cleaning off the new (ruined gasket) and removing the snapped bolt I start to put it back together. Second bolt in and I snap another bolt.

I'm no mechanic or superman, but I must be doing something wrong here. Any ideas?