Mac5005

Well-Known Member

- Joined

- Oct 19, 2005

- Location

- Rocky Mount

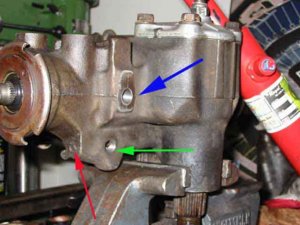

Ok, So i Know where and what size to drill in my steering box, and have the tap, to tap the holes.

I have read all over pirate, and searched everywhere, and can't figure out one little aspect, But I also ahvent pulled the box apart yet to see if It would answer my own question.

I have seen that people needed to cut the end off there tap to keep it from bottoming out in the new holes. I have also heard that it is not necessary to completely dissasemble the box for drilling/tapping, although you then would have to worry abou getting metal shavings/filings inside your box and possibly ruining the seals etc.

So, whoever has done this before, is it really necessary to cut off the end of the tap?, and is it really necessary to completely dissasemble the box?

Just curious, and I already have the Entire seal kit for the box, if I need to tear it down, and reassemble, I can. I was planning on tearing it down all the way, just so I could replace all the seals in the box, but if I dont have to, then it would save some time.

Thanks,

Scott

I have read all over pirate, and searched everywhere, and can't figure out one little aspect, But I also ahvent pulled the box apart yet to see if It would answer my own question.

I have seen that people needed to cut the end off there tap to keep it from bottoming out in the new holes. I have also heard that it is not necessary to completely dissasemble the box for drilling/tapping, although you then would have to worry abou getting metal shavings/filings inside your box and possibly ruining the seals etc.

So, whoever has done this before, is it really necessary to cut off the end of the tap?, and is it really necessary to completely dissasemble the box?

Just curious, and I already have the Entire seal kit for the box, if I need to tear it down, and reassemble, I can. I was planning on tearing it down all the way, just so I could replace all the seals in the box, but if I dont have to, then it would save some time.

Thanks,

Scott