Ricky B

Wiiide Open

- Joined

- Mar 20, 2005

- Location

- LKN - Tha Dirty Mo (Mooresville, NC)

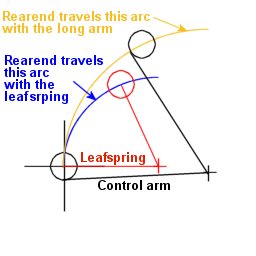

Ok so I've got two fairly reliable sources telling me that its ok/not ok, to run traction bars instead of a ladder bar, obviously the arguement is limiting of your flex?

I'm talking like a ladder bar that mount above and below of the axle and has a shackle at the frame vs the two single bars that you mount to the lower end of the axle that mount in the frame like the two bottom suspension links of a triangulated 4 link.

Also what thickness of tube should I go with? .25 wall? Bear in mind I have ROCKdubs (6.72 gears), big azz tires, and when I finish rebuilding my caddy 500 cubic inch motor with the performance parts I have I will be near the 400 hp - 650 ft lbs of torque range . . .

thanks

I'm talking like a ladder bar that mount above and below of the axle and has a shackle at the frame vs the two single bars that you mount to the lower end of the axle that mount in the frame like the two bottom suspension links of a triangulated 4 link.

Also what thickness of tube should I go with? .25 wall? Bear in mind I have ROCKdubs (6.72 gears), big azz tires, and when I finish rebuilding my caddy 500 cubic inch motor with the performance parts I have I will be near the 400 hp - 650 ft lbs of torque range . . .

thanks

You could stockpile a bunch and give them to me so that everytime you see me at uwharrie you can tell your friends "I'll be right back, I gave that douche those springs and I need a beer!"

You could stockpile a bunch and give them to me so that everytime you see me at uwharrie you can tell your friends "I'll be right back, I gave that douche those springs and I need a beer!"