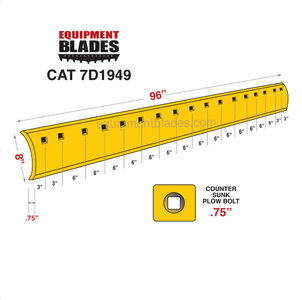

Looking for a blade/edge/not sure for a 8ft angle scraper.

Not sure on terms or where to look.

I’ve included a few pictures

Not sure on terms or where to look.

I’ve included a few pictures

Attachments

-

69F8A465-8568-4B51-BEA2-66E45C9C508A.jpeg237.6 KB · Views: 104

69F8A465-8568-4B51-BEA2-66E45C9C508A.jpeg237.6 KB · Views: 104 -

4973F660-1C8B-4147-BD7C-6DCD3D9B9554.jpeg309.6 KB · Views: 108

4973F660-1C8B-4147-BD7C-6DCD3D9B9554.jpeg309.6 KB · Views: 108 -

4E0078AE-26EE-4D3D-A0E3-655C9383E7B3.jpeg308.8 KB · Views: 110

4E0078AE-26EE-4D3D-A0E3-655C9383E7B3.jpeg308.8 KB · Views: 110 -

3FC8F07B-04BF-4E68-901E-C8174DC6B6B5.jpeg347.3 KB · Views: 101

3FC8F07B-04BF-4E68-901E-C8174DC6B6B5.jpeg347.3 KB · Views: 101 -

6B0B9E95-E99D-4569-A0CB-A72CCD2F2EFA.jpeg334.2 KB · Views: 103

6B0B9E95-E99D-4569-A0CB-A72CCD2F2EFA.jpeg334.2 KB · Views: 103 -

2D0144CC-9F81-4741-971E-8897EEA84F4C.jpeg331.5 KB · Views: 104

2D0144CC-9F81-4741-971E-8897EEA84F4C.jpeg331.5 KB · Views: 104