YJJPWrangler87

New Member

- Joined

- Mar 12, 2006

- Location

- Raleigh

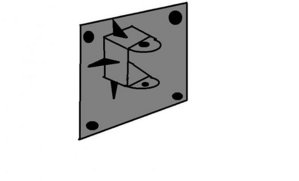

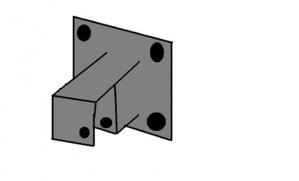

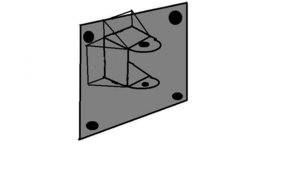

Alright, so I'm trying to decide on the design of an UCA bracket for an XJ, its a 3 link and after looking at the way RK has theirs, I was thinking of a way to do it for cheap and for it to be as strong or stronger. So I came up with these, please feel free to critique, approve, or completely trash the idea, I have my flame suit on also for those not familiar to the RK design, the mount bolts to the DS of the XJ via 4 bolts.

also for those not familiar to the RK design, the mount bolts to the DS of the XJ via 4 bolts.

Zack

also for those not familiar to the RK design, the mount bolts to the DS of the XJ via 4 bolts.

also for those not familiar to the RK design, the mount bolts to the DS of the XJ via 4 bolts.Zack