brengl1942

Well-Known Member

- Joined

- May 13, 2015

- Location

- Hurdle Mills

I'm trying to figure out why my flat fender keeps eating through pilot bushings. When I first got it on the road in 2021, it ate through the first bushing in roughly 50 miles. Last winter I replaced it with a second bushing after replacing the input shaft on the T-90 with a new NOS shaft. The input shaft was the only re-used internal part in the transmission in the initial build, and it had a fair amount of wear which I thought was part of the problem. I also replaced my cave-built homemade bellhousing with a very pricey Quicktime bell, to try and eliminate bellhousing alignment issues (long story, but there is no "adapter" for my engine/trans combo).

Now I have a basically new trans with very little play in the input shaft and a new bellhousing that as far as I could tell was within about .004" tolerance. It was difficult to check though since my gauge is designed for degreeing cams and didn't fit easily inside the bellhousing.

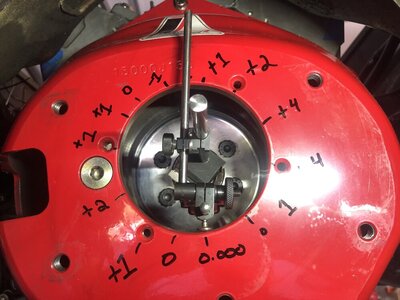

After this year probably putting a couple hundred miles on the jeep, I'm getting some nasty clutch chatter again and a little 'chirping' upon startup. In the photo, the 'rust' looking dust you see around the center hole in the flywheel and on the bolts, that is bronze dust where the bushing has disintegrated.

I've been wondering about the bushing material itself, these had to be custom made since there is no commercially available one for this combo. They were supposed to be "sintered bronze", but I don't think they were oil-lite. @amcjeepman has graciously made me a couple of new ones out of bronze, but I'm hesitant to just put a new one in and bolt it back together expecting a different result, without really knowing the cause of the problem. I don't want to have to pull it apart in another few months again.

Ideas? Maybe I need true Oillite material or something tougher than bronze? Buy a better alignment gauge and re-check the bellhousing alignment for issues? Are there other things that can cause this?

Now I have a basically new trans with very little play in the input shaft and a new bellhousing that as far as I could tell was within about .004" tolerance. It was difficult to check though since my gauge is designed for degreeing cams and didn't fit easily inside the bellhousing.

After this year probably putting a couple hundred miles on the jeep, I'm getting some nasty clutch chatter again and a little 'chirping' upon startup. In the photo, the 'rust' looking dust you see around the center hole in the flywheel and on the bolts, that is bronze dust where the bushing has disintegrated.

I've been wondering about the bushing material itself, these had to be custom made since there is no commercially available one for this combo. They were supposed to be "sintered bronze", but I don't think they were oil-lite. @amcjeepman has graciously made me a couple of new ones out of bronze, but I'm hesitant to just put a new one in and bolt it back together expecting a different result, without really knowing the cause of the problem. I don't want to have to pull it apart in another few months again.

Ideas? Maybe I need true Oillite material or something tougher than bronze? Buy a better alignment gauge and re-check the bellhousing alignment for issues? Are there other things that can cause this?