kaiser715

Doing hard time

- Joined

- Jun 1, 2006

- Location

- 7, Pocket, NC

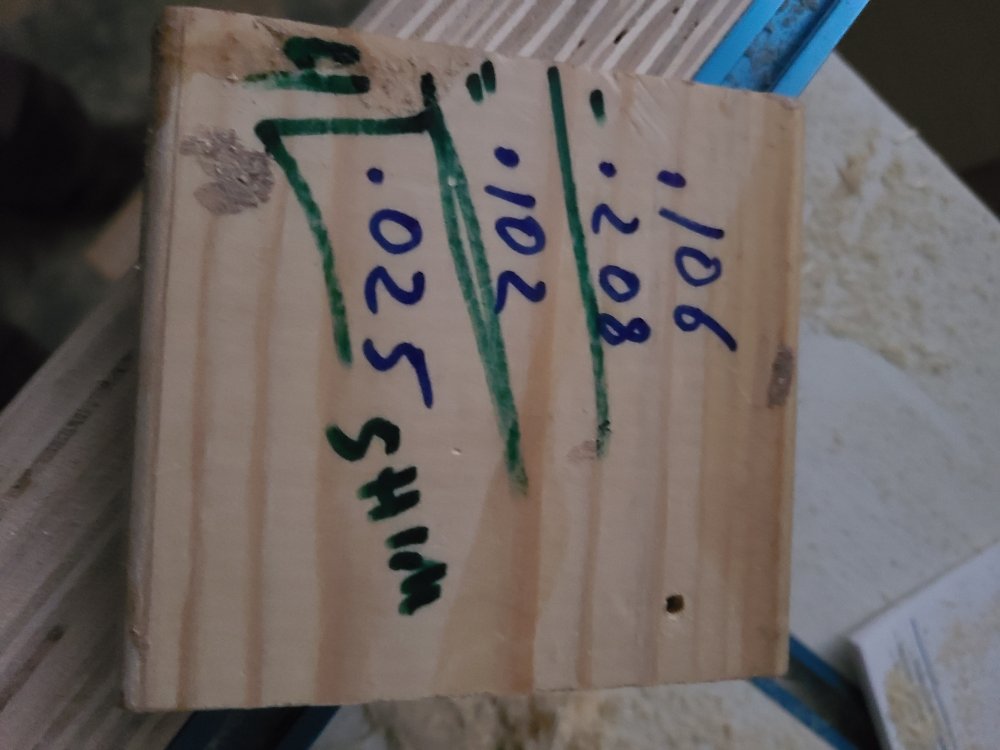

Got it mostly wrapped up today. Squared it to the fence and attached the slider rails on the bottom. Cut the slot, then did a 5-cut test for squaring the fence. Took a piece of 3/4" plywood 12" square, made a trimming cut on each side, rotating the board 1/4 turn each time. The fifth cut, I measured the thin cut-off with the calipers. .106 at one end, .208 at the other. Divide the difference by 4, and come up to needing a 0.025 shim on the right side of the fence. Got that in, and did another 5-pass cut, and the test piece came out .002 difference end-to-end. I am happy enough with that for wood work.

Sled stuck at first, used johnson wax on the bottom and runners and it does fine now.

Sled stuck at first, used johnson wax on the bottom and runners and it does fine now.