kaiser715

Doing hard time

- Joined

- Jun 1, 2006

- Location

- 7, Pocket, NC

I'd been looking for either a small forklift or a pallet stacker for a while, to make better use of the pallet racking and future loft in my shop. Last week, @Roughshod posted one up in the freebies section, and for once, I was faster than usual, and snagged it. You snooze, you lose. (Thanks again @Roughshod)

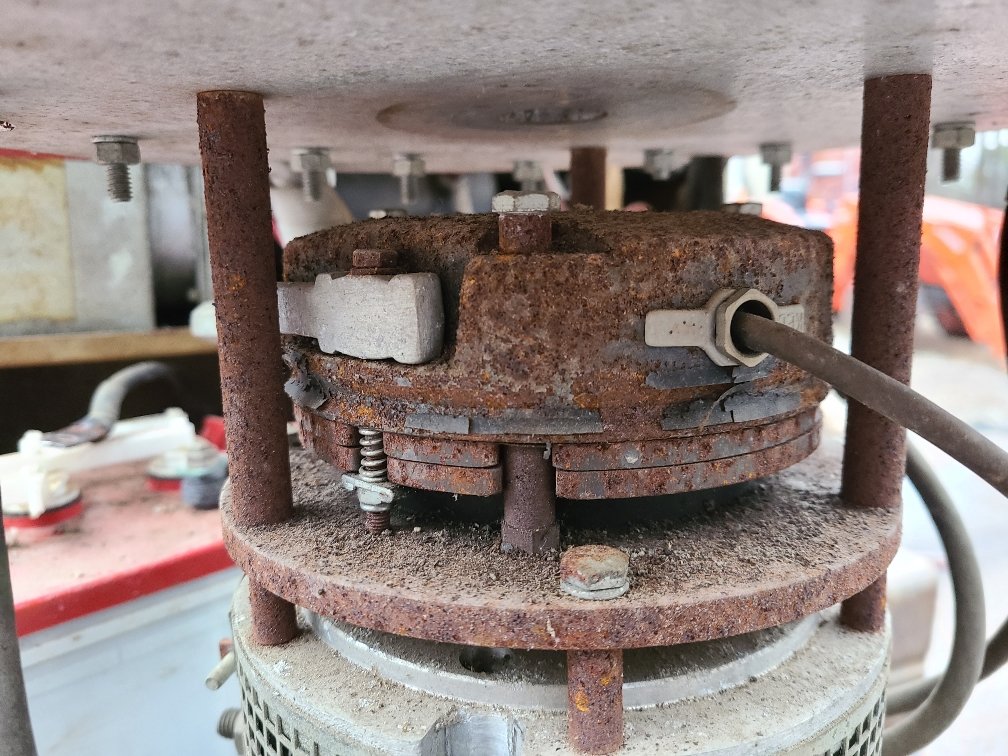

Got fresh batteries hooked to it and got it half working today. Uppitity-down works, motivation not so much. There is what appears to be a clutch type brake on top of the motor that is rusted together.

Got fresh batteries hooked to it and got it half working today. Uppitity-down works, motivation not so much. There is what appears to be a clutch type brake on top of the motor that is rusted together.