ncgamedog- you are right and that was a bit contradictory, I had remembered xj springs being mentioned and when I glanced back over your post and saw people running the 52s with success I took that as being a good option. I do also plan to keep the shackle in the rear which is against your advice but with the front mount already made I hope will be worthwhile.

MarsFab and ncgamedog- I wanted to put the shackle mount through the frame but due to frame width I was not able to, if possible when I move the mount forward I will do this but it doesn't look promising.

Before getting to the last weeks worth of pictures I was wondering, It looks like a 7 leaf wagoneer spring is the best option but If I can only find the 5 leaf version is that too soft or should I get a different set of springs? If I do have to get different springs it sounds like they should be off the front of a v8 truck, is this correct? Or in that case would the 52s be acceptable, I will follow whichever hierarchy is suggested but I have no money for new springs so I do need a fallback plan.

---------pics------------

Friday

mounted steering box, still need to add bracing but I'm not sure where to get tube to sleeve 7/16" bolts

steering box mounted

motor mount in the way

turns out I measured the outside diameter wrong so started shaving the drag link down

-------Saturday--------------

working on drag link

drag link shortened, steering shaft lengthened and end changed

At some point I went to walmart and got a dremel to clearance the motor mount but it didn't come with a collet nut and I didn't want to go back. All the shiny shavings are from the aluminum motor mount.

finally got enough clearance and then quit for the night

-------Sunday--------------

Reaming knuckle for drag link

when I thought it was finished

Drag link touching tire

Regular lug nuts

At some point between the steering pictures and here I bent the brake lines found out that the factory 10mm lines and brake caliper 3/8" banjo bolts are close enough and so far it is leak free. I also routed the power steering lines, the fittings are the same but my lines currently make a big U.

Sitting a little leaned back

Starting rear shackle flip

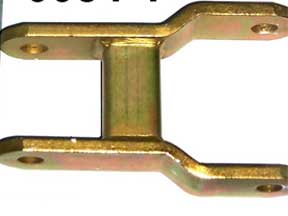

shackle flip finished

closer to level, about 1.5" lower in the rear

current terrible pinion angle

driving it onto something in the yard just to see

Edit: The front shocks I bought were for a K5 blazer, the parts guy said they were for a factory dual shock setup, are there any better options for a front shock off a stock vehicle?