dieselfuelonly

Well-Known Member

- Joined

- Feb 9, 2008

- Location

- Chapel Hill, NC

Well, I have 5 more days until I've got to head down to ECU. Ugh. Shoulda worked for a year, but... whatever. Of course I procrastinated on the swap.

PART I:

Picked up the rest of the stuff I need for the swap, minus the flywheel bolts. UPS hadn't delivered them to Phil yet (or something happened to them after they arrived, we don't know).

1. Got the flywheel that was in the donor truck resurfaced. Looks great.

2. New clutch - South Bend clutch rated for 350HP, 700ft/lbs of torque. If the guy that bought the cab of the donor truck would have showed up 2 days earlier, I would have gone up to the 400HP clutch, but, too late now, I can always upgrade later. Not like I'm anywhere near 350HP now anyway.

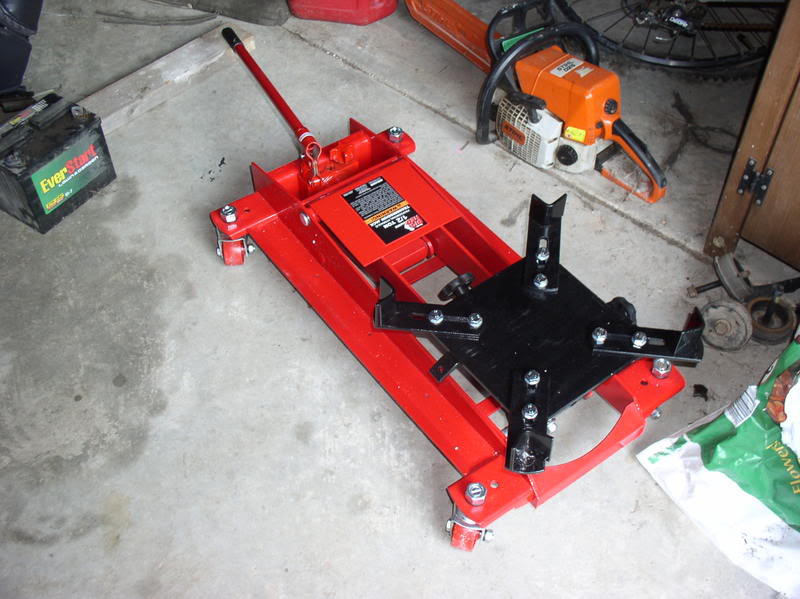

3. Stopped by Northern Tool on the way home. Bought a 16mm wrench (as I had 4 15mm wrenches, 5 17mm wrenches, but apparently ZERO 16mm wrenches, WTF??), 2 sets of jack stands, as I couldn't remember what the set I had currently were rated for (stupid frickin' 2WD truck is too low and will be need to have all four corners off the ground in order to get the auto tranny out and manual tranny in), a little set of 1/2" sockets and a wrench, needed a wrench as my other 1/2" wrench disappeared, and a trans jack. Picked up my floor jack from the old house and mowed the lawn there (please, someone buy that damn house) on the way too.

Part II:

Drive truck in garage.

Stop JUST in time before backing into your NV4500.

Support the front of the truck with jack stands to make it easier to work under if you have a 2WD. Really wish it was a 4x4. Really like those dual-locking jack stands.

PART I:

Picked up the rest of the stuff I need for the swap, minus the flywheel bolts. UPS hadn't delivered them to Phil yet (or something happened to them after they arrived, we don't know).

1. Got the flywheel that was in the donor truck resurfaced. Looks great.

2. New clutch - South Bend clutch rated for 350HP, 700ft/lbs of torque. If the guy that bought the cab of the donor truck would have showed up 2 days earlier, I would have gone up to the 400HP clutch, but, too late now, I can always upgrade later. Not like I'm anywhere near 350HP now anyway.

3. Stopped by Northern Tool on the way home. Bought a 16mm wrench (as I had 4 15mm wrenches, 5 17mm wrenches, but apparently ZERO 16mm wrenches, WTF??), 2 sets of jack stands, as I couldn't remember what the set I had currently were rated for (stupid frickin' 2WD truck is too low and will be need to have all four corners off the ground in order to get the auto tranny out and manual tranny in), a little set of 1/2" sockets and a wrench, needed a wrench as my other 1/2" wrench disappeared, and a trans jack. Picked up my floor jack from the old house and mowed the lawn there (please, someone buy that damn house) on the way too.

Part II:

Drive truck in garage.

Stop JUST in time before backing into your NV4500.

Support the front of the truck with jack stands to make it easier to work under if you have a 2WD. Really wish it was a 4x4. Really like those dual-locking jack stands.

.

.

.

.