mcutler

Well-Known Member

- Joined

- Apr 17, 2010

- Location

- mt.airy nc

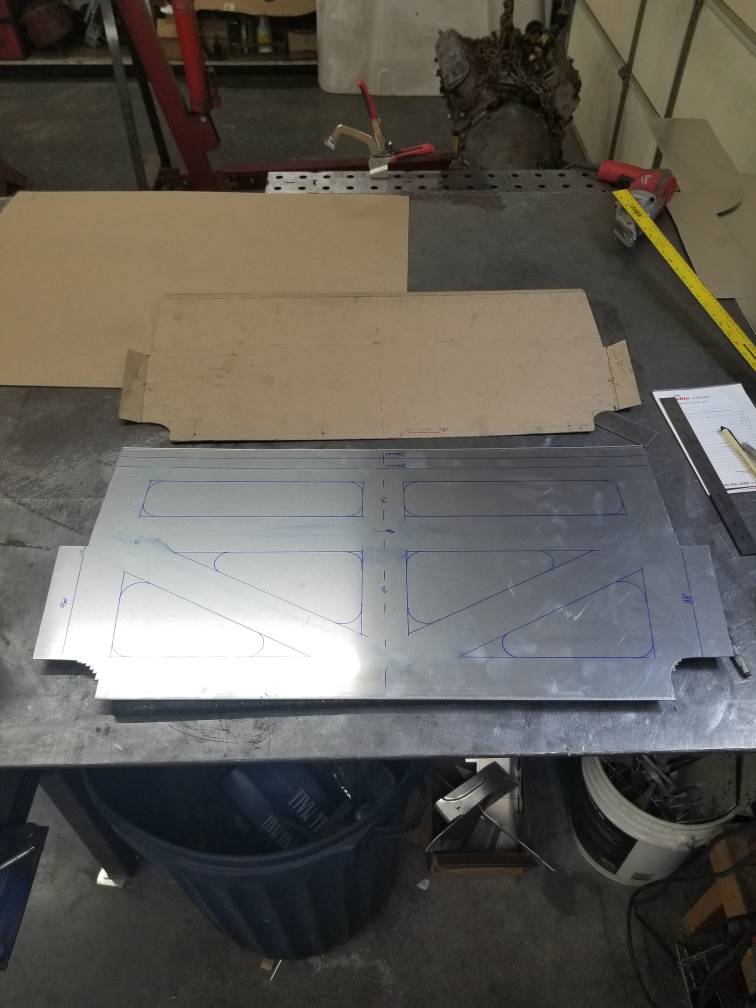

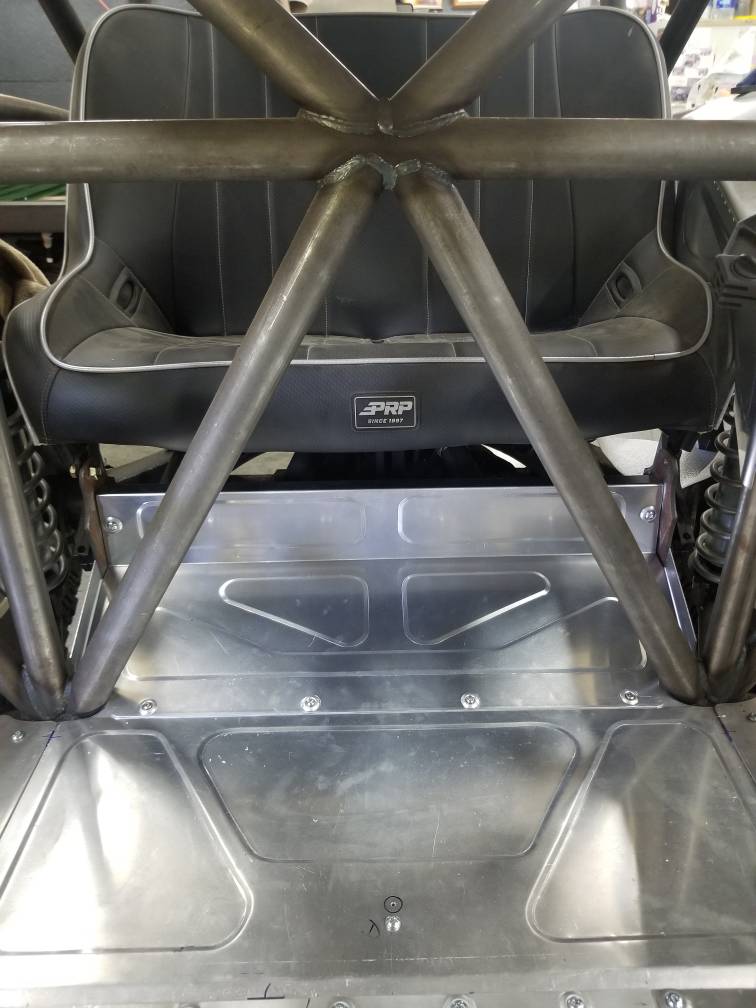

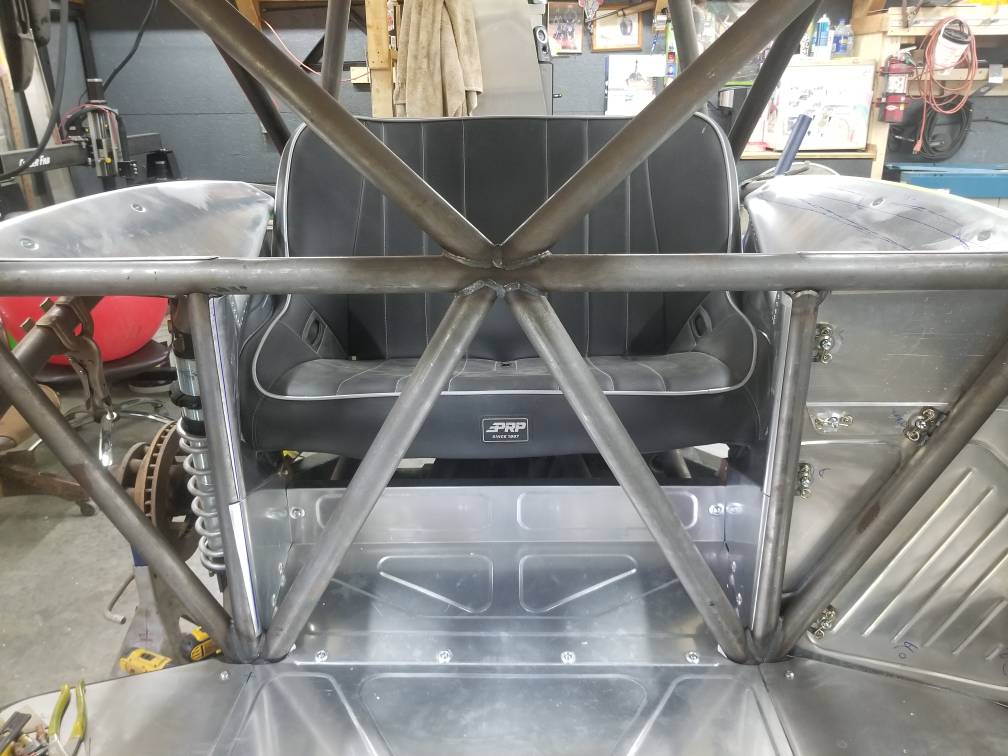

Also got started on the rear seat area for the kiddos... no pinch points!

CutlerFab

Sent from my SM-G892A using Tapatalk

CutlerFab

Sent from my SM-G892A using Tapatalk