Is the weight saved in designing components like this worth the added shop time to weld it all up?

Copied from similar question in killer weld thread.

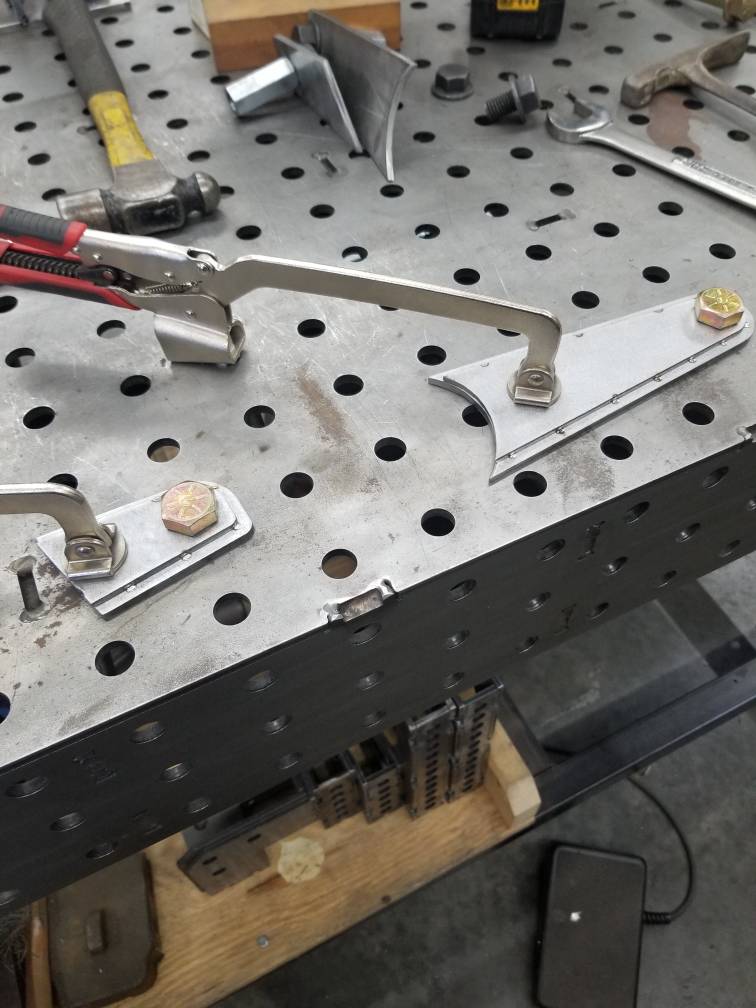

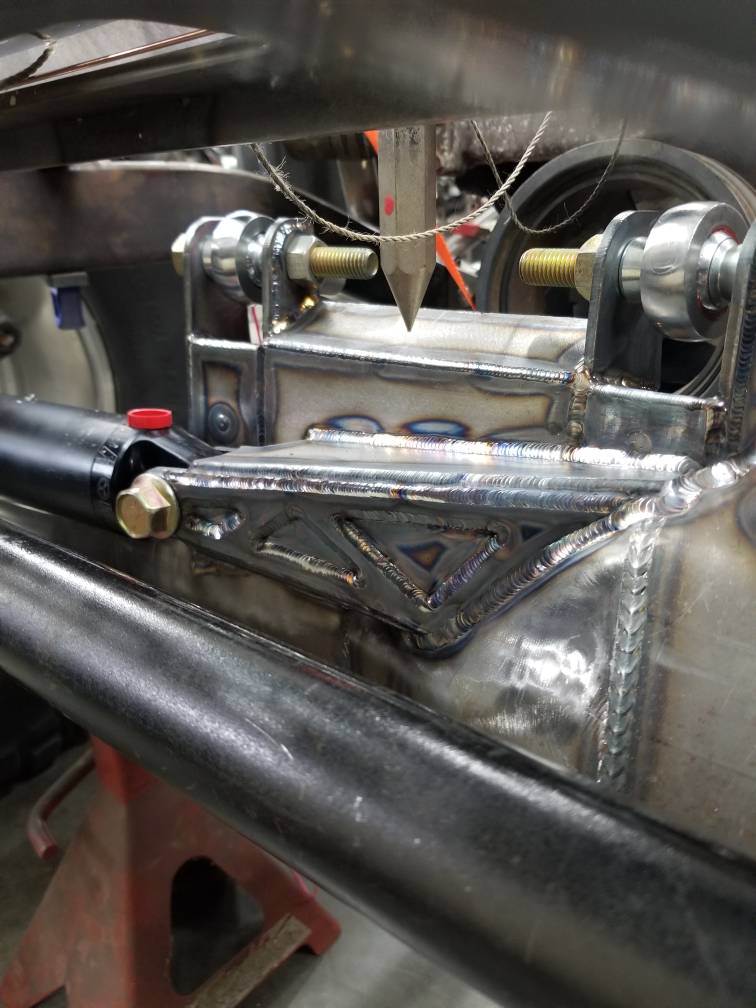

-First would be weight. Anyone could use 3/8 and be done. (But where's the art in that...[emoji16]). Albeit not much difference, in the unsprung area, it all adds up. Here I got the beef of 5/16 at the bolt and joints without the heft of 3/8.

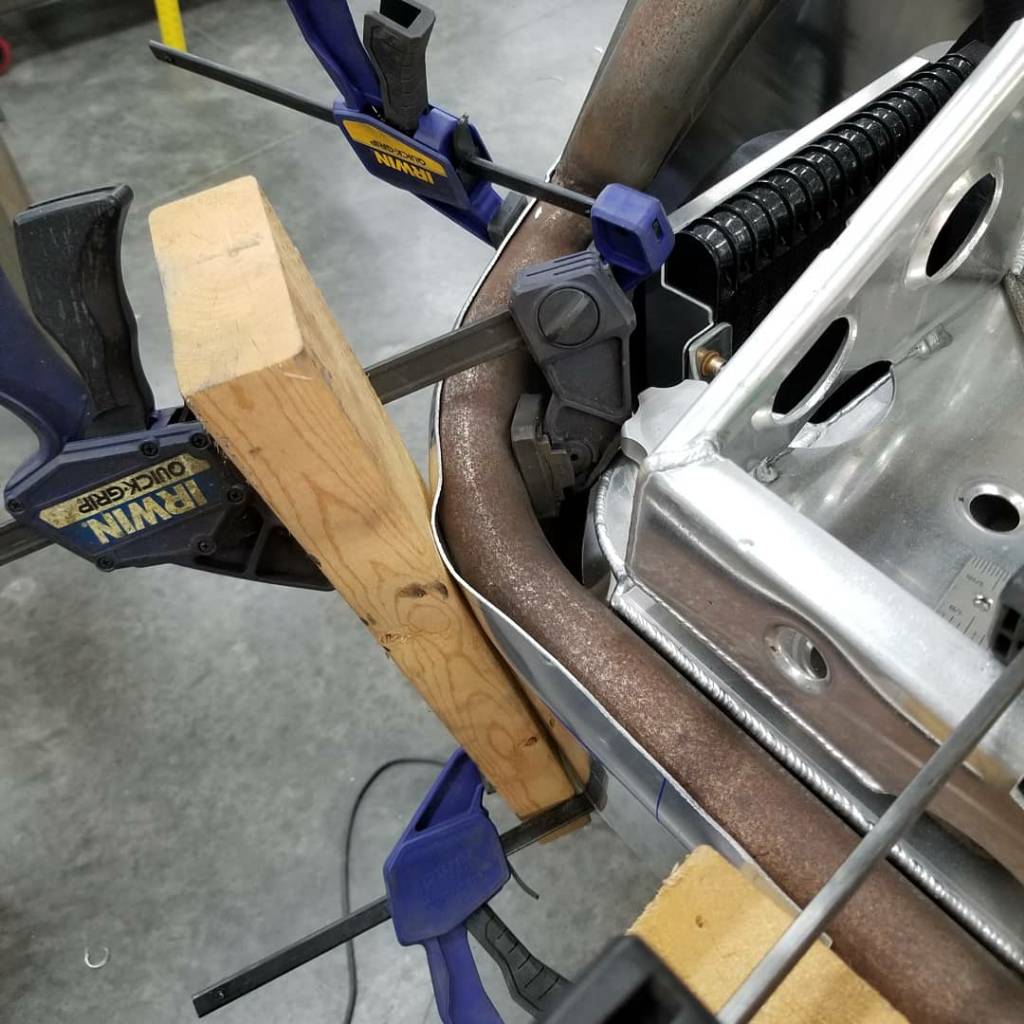

-As far as heat into the tube; proper weld sequence, back stepping, and bead length/ orientation will assist in keeping the tubing from having terrible distortion. (Note: not one weld against or near the tubing, on either housing, either root or cover, was welded more than 2" at a time. ) But this particular area isn't going to pull terribly as its not direct to the tube. There will always be shrinking of weld joints, but proper planning can help alleviate headaches later.

-I have a true bar fixture and pucks to check run out, and determine if and where further shrinkage should occur.

- thirdly: customers call me (I hope) because I don't just throw 3/8 at everything and call it good. I apply form and function with a heavy dose of creativity.

- last- customer wanted strong and light. I build what is asked with my creative license.

Matt

Since I wrote that, I have checked the rear axle with the true bar... less than 1/16" deflection on either end at the inner C. I'd say my weld planning worked out nicely. I was told by very a reputable axle builder that up to 1/8 was acceptable on a steer axle... but I decided to get them dead on....

Btw, I invested almost $1000 in a quality ground chrome bar and pucks for Ford unit bearings 99- current, Dana 60/70/14b/9-10" spindle sleeves and pucks for tubing from 3" thru 4"; only because I knew I had 3 housings to build (so far). They must be right by my standards.

.... short answer... yes, I love welding, so it is definitely worth the time to me. I hope as I continue to improve it will also be worth it to my customer base as well.