fordtrucknut

Well-Known Member

- Joined

- May 16, 2012

- Location

- bedford va

Ok so how far foward is yours stretched?

What pitman arm are you currently running?

Are you aware there are 3 different astro steering boxes? Do you know which one you are using?

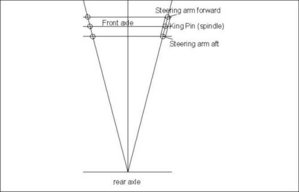

I am in the middle of building my steering..my concern with mine was the angle of the drag link..but I was concerned with having too much angle..where it seems you think your issue is not having enough of an angle

I have debated going full hydro.. but I want to drive mine on the street and most folks so full hydro on the street doesn't work well

What pitman arm are you currently running?

Are you aware there are 3 different astro steering boxes? Do you know which one you are using?

I am in the middle of building my steering..my concern with mine was the angle of the drag link..but I was concerned with having too much angle..where it seems you think your issue is not having enough of an angle

I have debated going full hydro.. but I want to drive mine on the street and most folks so full hydro on the street doesn't work well

), but have DL clearance issues under the PS leaf and was thinking about a similar "fix" (DL to TR). Should be fine, but would have a pretty steep angle from pitman arm to TR given the narrow-gauge axle. Since the steering box mount is now bullet-proofed, along with 1.125" x .375" wall DOM DL/TRE... that would make the @#$% arms the "weak link"!

), but have DL clearance issues under the PS leaf and was thinking about a similar "fix" (DL to TR). Should be fine, but would have a pretty steep angle from pitman arm to TR given the narrow-gauge axle. Since the steering box mount is now bullet-proofed, along with 1.125" x .375" wall DOM DL/TRE... that would make the @#$% arms the "weak link"!