- Joined

- Mar 24, 2005

- Location

- Stanley, NC

Nothing too fancy here. Just consolidating, sold off some of my bigger equipment, and trying to organize things a little better in the shop. I have this real bad tendency of spending 1/3 of my time in the shop walking somewhere else to get the thing I need and know where it is, 1/3 of my time looking for the tape measure (which I have like 4 of, all brightly colored, always set in an easy to find spot that I can never remember and never see from wherever I am), and the other 1/3 cussing and cobbling stuff together.

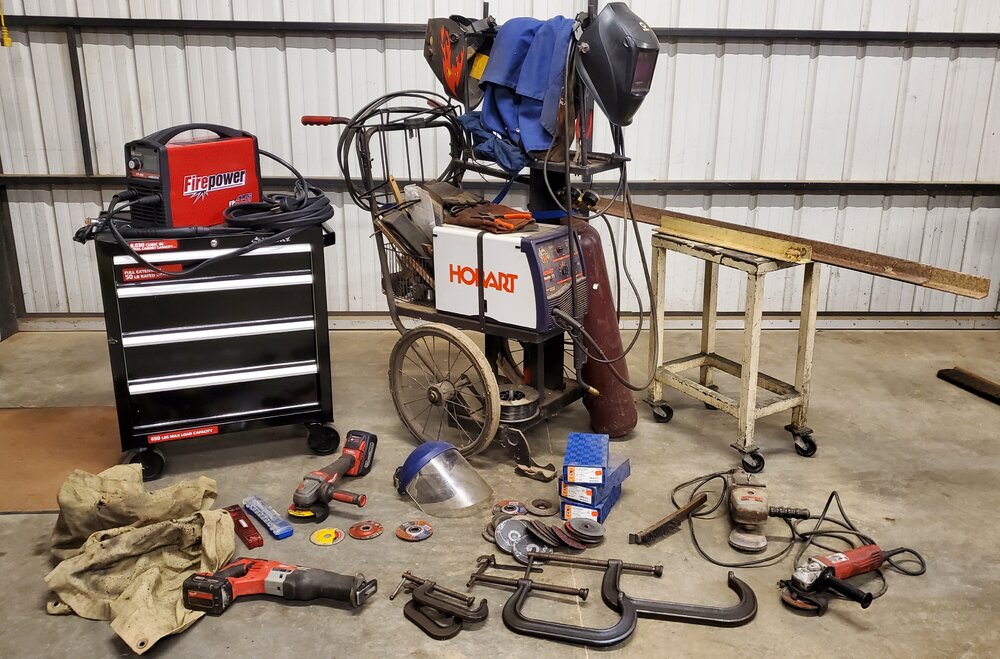

Some low hanging fruit was the welding/fab/grinding side of things. I always have a few C-clamps and some gloves and a grinding disc on the welding table, my grinders either in the top of the toolbox, under the back workbench, or wherever I last used them, my welder parked over in a corner with half of the stuff I need to weld hanging on it, and the plasma on a totally separate cart in a different corner of the shop.

Step 1 was to sell my big Miller welder and Esab plasma (thanks @Mac5005 and @KrawlerTJ ), figure out what was wrong with my trusty old Hobart 175, and buy a smaller plasma cutter. The Hobart had been haunting me for over a year with feed issues (only feeding wire at 90-100% speed) and it turned out to simply be an overtightened feed roller tensioner that i forgot to loosen after I did this.

), figure out what was wrong with my trusty old Hobart 175, and buy a smaller plasma cutter. The Hobart had been haunting me for over a year with feed issues (only feeding wire at 90-100% speed) and it turned out to simply be an overtightened feed roller tensioner that i forgot to loosen after I did this.

Next step was to buy a smaller plasma and a toolbox to put it all on. I wanted all drawers to generally keep it dust/slag free, and deeper drawers to fit taller items instead of a bunch of short drawers that would be nearly empty and a couple of packed big drawers at the bottom. Craftsman and Husky both had 4 drawer toolboxes for $150, but the Husky seemed a little better built. Then found a great deal on a Firepower plasma which is an Esab/Thermal Dynamics brand (that I had never heard of either).

Pretty sure this is the first shop tool I've ever owned with a fancy digital display...

So here's the plan, everything in this pic needs to be in or on the new cart. Using the angle to build a new subframe that holds the toolbox and tanks and forms a beefier base for it all to roll on, with a longer wheelbase and wider spacing on the casters for stability.

Some low hanging fruit was the welding/fab/grinding side of things. I always have a few C-clamps and some gloves and a grinding disc on the welding table, my grinders either in the top of the toolbox, under the back workbench, or wherever I last used them, my welder parked over in a corner with half of the stuff I need to weld hanging on it, and the plasma on a totally separate cart in a different corner of the shop.

Step 1 was to sell my big Miller welder and Esab plasma (thanks @Mac5005 and @KrawlerTJ

), figure out what was wrong with my trusty old Hobart 175, and buy a smaller plasma cutter. The Hobart had been haunting me for over a year with feed issues (only feeding wire at 90-100% speed) and it turned out to simply be an overtightened feed roller tensioner that i forgot to loosen after I did this.

), figure out what was wrong with my trusty old Hobart 175, and buy a smaller plasma cutter. The Hobart had been haunting me for over a year with feed issues (only feeding wire at 90-100% speed) and it turned out to simply be an overtightened feed roller tensioner that i forgot to loosen after I did this.

Next step was to buy a smaller plasma and a toolbox to put it all on. I wanted all drawers to generally keep it dust/slag free, and deeper drawers to fit taller items instead of a bunch of short drawers that would be nearly empty and a couple of packed big drawers at the bottom. Craftsman and Husky both had 4 drawer toolboxes for $150, but the Husky seemed a little better built. Then found a great deal on a Firepower plasma which is an Esab/Thermal Dynamics brand (that I had never heard of either).

Pretty sure this is the first shop tool I've ever owned with a fancy digital display...

So here's the plan, everything in this pic needs to be in or on the new cart. Using the angle to build a new subframe that holds the toolbox and tanks and forms a beefier base for it all to roll on, with a longer wheelbase and wider spacing on the casters for stability.