maulcruiser

Well-Known Member

- Joined

- Aug 13, 2005

- Location

- Bladenboro/Wilmington, NC

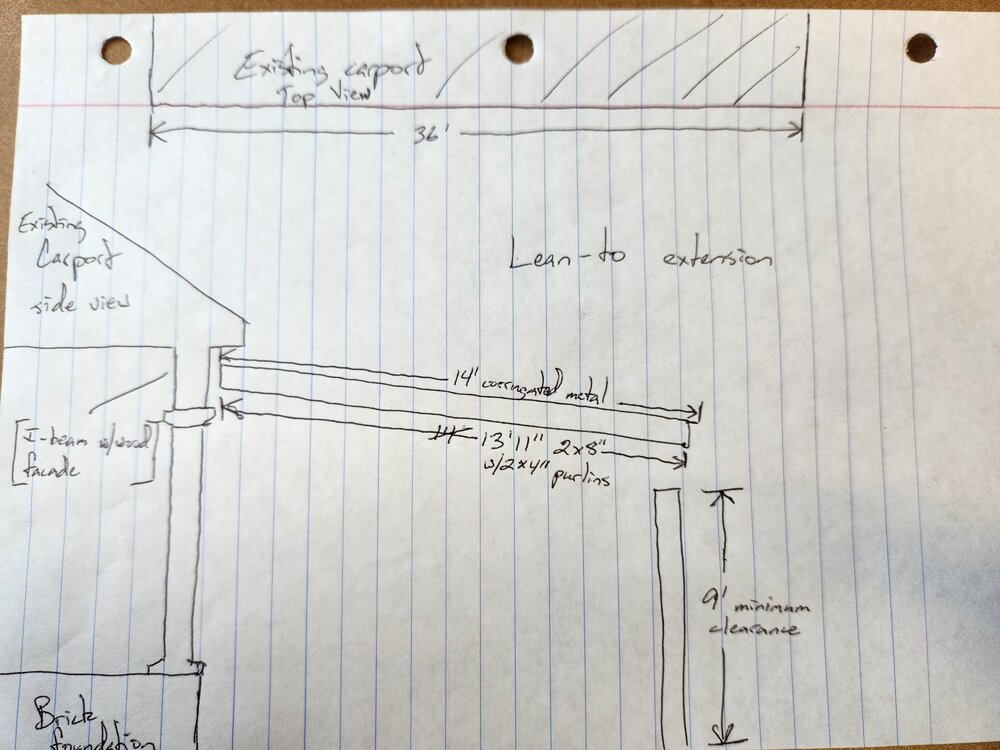

Simply put, I need to know what size steel beam to use for a lean to. Excuse my crude drawing. I need to know what size horizontal beam to use for the 36' span. 800 lb dead load evenly distributed. Need more info? Please ask. No one locally wants to just tell me that size, and I'm not exactly wanting to overkill it.