MetalCraftSolved

Well-Known Member

- Joined

- Jun 20, 2010

- Location

- NC

Lets see those Badass, Custom made parts, mounts, tube joints, etc.... and the Killer welds that come with them

.

.

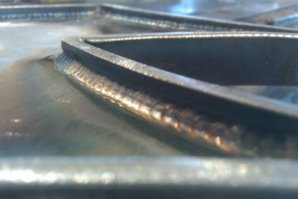

So consider this a sneak peak of what it'll be. The axle pictures are also from the same buggy and is all MIG welded.

So consider this a sneak peak of what it'll be. The axle pictures are also from the same buggy and is all MIG welded.

Haha, Come on with it, I got plenty....Those aren't my welds guys. They were done by the thread starter. I was just joking that he started this thread.

Might as well have been titled "Hey, I'm a badass welder."

My welds look much better than that...but I don't ever take pictures.

I'll try to get a few close ups of the radiator support and header, the support is all tig welded cold rolled and weighs less than 4 lbs. The header is 304 stainless. Its on a fully tig welded single seat chassis I'm building for a customer that wants to keep it top secretSo consider this a sneak peak of what it'll be. The axle pictures are also from the same buggy and is all MIG welded.

your headers are badass on that 22RE

your headers are badass on that 22RENice Work!your headers are badass on that 22RE

.

.

Damn wish I had some pics to post ......but mine look like shit.

Damn wish I had some pics to post ......but mine look like shit.Here's some TIG'n closeups from today...

ha maybe you guys can help me weld up my roll cage. im so out of practice. my welds look like poop right now