SHINTON

Well-Known Member

- Joined

- Mar 17, 2005

- Location

- Triad area of NC

Ok, 6psi on TSLS have ALOT more traction than the M/Ts did with 15psi and my steering box / current setup just did not give me all the steering I wanted this weekend.

I had mentioned to you folks before, I have bought a RAM assist with a 6" throw, and my current "throw" on the tie rod is about 5.5", I will adjust the stops so the RAM will be the "stops" after this install.

Ok, so my question is, how to mount it...previous discussions have included building a mount on a diff cover guard, some pros, some cons, and I am leaning towards the following welded to the axle tube instead.

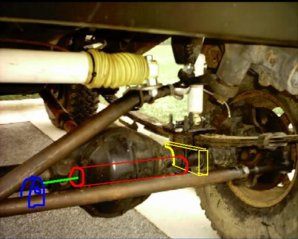

It is a bit hard to see in the picture, but there is approx 2" or more, between the diff and the spring plate and I am wanting to weld my ram mount to the tube there, sandwiching it if you will.

What I have attempted to draw is this... a 2" x 3ish" box tube, notched on one end to match the curve of the tube. This box would stick out OVER the tie rod so that my hydro ram would literally run parallell to the tie rod. (This is a good thing I understand)

Then I would "simply" weld 2 ears on the tie rod itself for the other end of the ram to bolt to.

Please take a look, feedback is HIGHLY desired, this is my NUMBER one goal between now and Windrock (first weekend in May)

Sam

I had mentioned to you folks before, I have bought a RAM assist with a 6" throw, and my current "throw" on the tie rod is about 5.5", I will adjust the stops so the RAM will be the "stops" after this install.

Ok, so my question is, how to mount it...previous discussions have included building a mount on a diff cover guard, some pros, some cons, and I am leaning towards the following welded to the axle tube instead.

It is a bit hard to see in the picture, but there is approx 2" or more, between the diff and the spring plate and I am wanting to weld my ram mount to the tube there, sandwiching it if you will.

What I have attempted to draw is this... a 2" x 3ish" box tube, notched on one end to match the curve of the tube. This box would stick out OVER the tie rod so that my hydro ram would literally run parallell to the tie rod. (This is a good thing I understand)

Then I would "simply" weld 2 ears on the tie rod itself for the other end of the ram to bolt to.

Please take a look, feedback is HIGHLY desired, this is my NUMBER one goal between now and Windrock (first weekend in May)

Sam