Granny

One day at a time...

- Joined

- Jun 12, 2007

- Location

- Cabarrus County (Rimertown)

NOTE: for the record, not a build thread... YET!

Still have no idea what the outcome will be... BUT.....

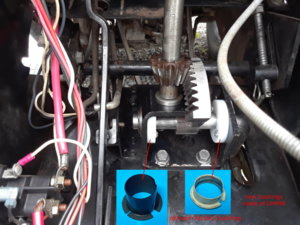

In true fashion of a "Big Dog" build thread I have decided to follow examples I have seen previously. I can't begin to guess how many "machines" (Jeeps, chassis, frames, etc.) in various states from basket-case up I have seen in photos posted proudly along side numerous $$$$ worth of Goodyears, Nittos, Swampers, beadlocks, etc. Many times it has appeared questionable as to whether or not the "machine" will even run, but the new tires and rims are very real... and pretty!

So-o-o-o... as stated above... "in true fashion" here is my "machine" along with its new rubber (sorry, couldn't find beadlocks that fit). Now I too have no idea, at this time, whether or not this "machine" will even run, but the new tires are very real... and pretty! Also, as mentioned above, I have no idea as to the outcome or if it will turn into a build thread, but at any rate when the weather warms up in the spring I will see where the project leads... and will make an attempt at keeping y'all informed. Bet ya can't wait!

Moderators: if this needs to be moved I will not be the least bit offended.

Still have no idea what the outcome will be... BUT.....

In true fashion of a "Big Dog" build thread I have decided to follow examples I have seen previously. I can't begin to guess how many "machines" (Jeeps, chassis, frames, etc.) in various states from basket-case up I have seen in photos posted proudly along side numerous $$$$ worth of Goodyears, Nittos, Swampers, beadlocks, etc. Many times it has appeared questionable as to whether or not the "machine" will even run, but the new tires and rims are very real... and pretty!

So-o-o-o... as stated above... "in true fashion" here is my "machine" along with its new rubber (sorry, couldn't find beadlocks that fit). Now I too have no idea, at this time, whether or not this "machine" will even run, but the new tires are very real... and pretty! Also, as mentioned above, I have no idea as to the outcome or if it will turn into a build thread, but at any rate when the weather warms up in the spring I will see where the project leads... and will make an attempt at keeping y'all informed. Bet ya can't wait!

Moderators: if this needs to be moved I will not be the least bit offended.