SSWaters

Old Member

- Joined

- Mar 22, 2005

- Location

- Kannapolis

I thought I'd start a thread on this, I'm guessing there must be at least 20 of you on here that are running these and I just bought my first set. Can we have a common area for ideas and information? Could probably do the same for 44's, 60's, 14B's and 70's.

My plan is to street mine and offroad it when finished, others probably just want to offroad theirs (which would be considerably cheaper).

So far my useful links;

www.whiteowl.com Parts

www.ouversonengineering.com HD Components

www.odiron.com Parts

www.usa6x6.com Parts OUT OF BUSINESS

www.chuckstrucks.net Parts OUT OF BUSINESS

www.longswheel.com Custom Big Wheels, out of Jacksonville, FL. Don't know if they do bead locks but you can weld them on yourself afterwords.

Others are Big Wheel Off Road (Bob), Boyce Equipment, Rock Mafia, bottomland4x4 (Eric V), Aaron871, Mudpro, Firetoy, Ricky and those "Farm/Big Dixe Bogger" guys on this board.

AXLE

I've shaved the pan and put in 1/2" plate. I cut around a 6" diameter hole which gave the Bull Gear around 1 1/2-2" internal clearance (enough for a bolt to clear if one lets go plus enough oil to run the street I hope). Normal dirrection is with the fill plug to the rear.

WMS 79 1/2" hubs out.

WMS 69 1/4" hubs in.

WMS narrowed is 72" I think.

AXLE STRIPPING

RR AXLE

Torch out or grind/chisel the rivet heads FLUSH on the inner side of the backing plate axle flange, smack the backing plate brake assembly with a sledge hammer to drive it off the flange. I've done 14 axles now and this is the easiest way I've found.

FRT AXLE

When taking the king pin caps off, don't lose the spacers under the plate. The spacers go under the top plate. The top and bottom bushing plates are different sizes. They'll stick to the grease and you'll about throw them away like I did.

FRONT AXLE INNER SEAL HOLDERS

Don't waste your time with a slide hammer. If the center section is out slide a 6' piece of pipe all the way through and smack it twice with a sledge hammer, it will sail out of there.

REAR HUB BRAKES

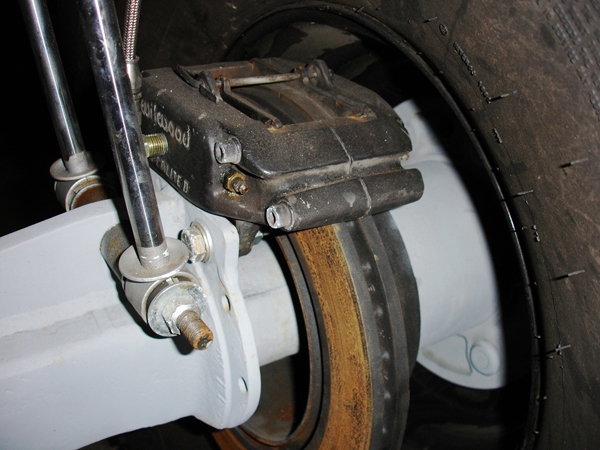

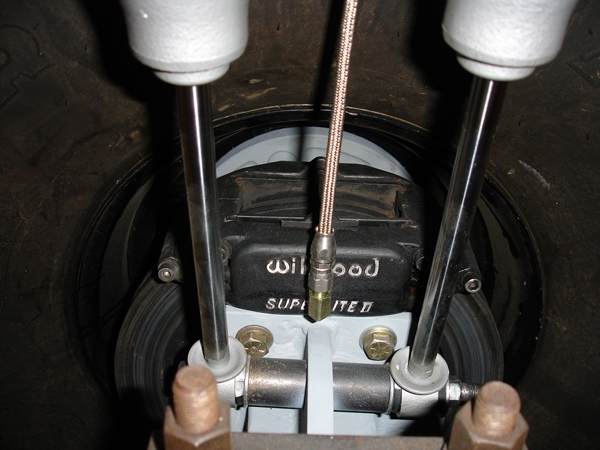

I'm gon'na run "hubs out" so I worked on a low buck hub disc brake set up for the rear. So far I've put in the 8 bolt hub drive pattern in a 2001 1 ton Chevy rear disc (this clears the hub seal) and mounted it to the Rockwell hub. Welded a flat plate extension off of the brake backing plate flange so I can run disc on all four corners. Planning to run 16.5 wheels with 6" backspacing, I figure most people bought their tires for 8 lug stuff anyway so this way they don't have to buy new tires. Can't run a pinion on the front 'cause I want to run lockouts (would have to be locked in all the time for brakes with the pinion brake). Ended up using Wilwoods on the rear since I had already put some on the front. It looked like I could have made a frt. caliper off a Chevy 4x4 fit but didn't persue it once I decided to go Wilwood.

FRONT HUB BRAKES

I had used the USA6X6 wheel hub brake adapters (see bottom of page for new setup) since I had 16.5 wheels, bought the brackets and adapter from Daniel. Bought the Wilwood calipers, disc and pads locally cheaper. If you use these get the 1" longer studs if you want a little thread beyond your lug nuts. If you have 20" or larger wheels I would go with the F550 Calipers and School Bus rotors instead.

USA6X6 brackets and aluminum hat adapters, He's up to $175 now on this, was like $125.

Wilwood Forged Dynalite 120-6814 around $125 each (Summit/Jegs). Rich stated Wilwood "Dynapro 6's" will work also, have more bite.

Wilwood Rotors 160-2894 LH & 160-2895 RH around $50 each (Summit/Jegs).

Wilwood Polymatrix Pads 7112 Series $40 to $175 (depending on compound).

Front USA6X6 adapters, buy the 1" longer studs so you will have extra lug stud thread sticking out. You will have to grind round the USA6X6 bracket edge so it will lay flat against the hub flange.

BULL GEAR

From JP Magazine- 8 bolts around bull gear 105 ft lbs, 4 main caps 175 ft lbs. Pinion nuts 300-400 ft lbs. All bolts are saftied/cotter keyed so they don't back off. Nuts on bull gear face opposite of inputs. One side of the bull gear is chamfered, I put it back in like it came out, on light rigs it probably doesn't matter anyway.

AXLE BOOTS

Get thick one piece ones that last!

HUBS

Inner and outer races are the same PN, bearings are different. Big bearing to the inside, hubs don't care which way they are flipped because the races are the same.

Wheel Bearings - Bearings 3994 and 392

(one of these bearings is the same as a 14 Bolt Gm, let me figure it out again)

Wheel Studs - Euclid brand PN is E-5871-R

Hub Race - Timken brand PN is 3920 (same race using both size bearings so you can flip it)

FRONT AXLE SHAFT U JOINT PART NUMBERS

Rockwell 750N

Precision U joint 898

GMB 230-0075

Size is 5 1/16" across X 1 5/8" caps

CENTER SECTION

I was told by George if you want to flip it 4 bolt holes line up (input to the left or right). You have to drill and tap the housing or drill the center section for the other bolts/studs to mount it.

There is a spacer under the frt pinion yoke and not the rr, don't let it fall out and lose it.

On the trucks the fill hole is to the rr on both axles.

Carrier Race - Timken brand PN is 394AS

Carrier Bearing - Bearing 395 and Race is 394A Timken Numbers, I also got an MS number of MS19081-103 (someone let me know if these are wrong)

Pinion Bearings - Bearing Small 22780 and Race Small 22720, Bearing Large 29585 and Race Large 29521 Timkens

Pinion Seal - 23695 ? (not sure of this number)

HD Chevy rr disc installed on Rockwell hub, Wilwood calipers on extensions welded to axle brake backing plate flange. (hard to see but you get the idea)

HD Chevy rr disc bolted to the Rockwell hub (drilled in the hub pattern) with calipers bolted to flat plat extensions welded to the Rock flange.

Welded and filled spiders, ground to balance it out.

My steering assist set up, 8" throw inline with tierod. You can mount this anywhere as long as you get the travel right and centered.

BELOW Pictures 2/09/12 Front Hub Disc spacer mount idea, using above Wilwood PN's

Rockwell Disc Brake

SSWaters, Feb 10, 2012

George G. came over to the house and got me thinking about front disc again, this is my after work brainstorming. The spacer replaces the above USA6X6 Adapter Plate.

It would be "hub out only".

If you wanted to run a larger outside diameter disc just make the caliper bracket taller accordingly.

Will probably counter sink the spacer to hub mount bolts or use flush heads (it bolts thru the hub sideways). Kind'a close to caliper like this but it was my first try. I guess you could weld this but I don't like welding hot roll DOM to cast, even if you're certified to weld iconel underwater on the moon or magnesium on venus.

Would use high strength cap head bolts on the rotor to spacer mount, just didn't have any at work. Would safety wire those also, like I did these, don't just trust locktite by itself on the disc.

The disc you have to grind a hair off each tang to slide it down on the hub (1/16" to 1/8"). Don't pay any attention to my scribbling on it.

The spacer is 7 1/2" OD by 1/2" wall DOM, could not find find 6 3/8" ID Tube at an affordable price for the weekend warrior (found it, just not affordable). Will have to grind out little "moons" in the bottom to clear the stud shoulders. ($65 delievered from Speedy Metals last week)

Since I had to go with 6 1/2" ID I shimmed this hub center with 20 gauge sheetmetal plates (Home Depot or Lowes), could use 18 or 22 gauge depending on your hub (I had bead blasted this one clean). 16 Gauge is way to tight, had to really beat in and got all jammed up. Would have went if I had ground the hub surface really smooth. Shim all the way around evenly before drilling hubs! Spacer bolts go through shims.

The Caliper mount is out of 3/8" thick steel, you will need 5" X 10" pice to make this.

Drill some holes, Tap some others, some grinding/cutting/fitting and no welding.

My plan is to street mine and offroad it when finished, others probably just want to offroad theirs (which would be considerably cheaper).

So far my useful links;

www.whiteowl.com Parts

www.ouversonengineering.com HD Components

www.odiron.com Parts

www.usa6x6.com Parts OUT OF BUSINESS

www.chuckstrucks.net Parts OUT OF BUSINESS

www.longswheel.com Custom Big Wheels, out of Jacksonville, FL. Don't know if they do bead locks but you can weld them on yourself afterwords.

Others are Big Wheel Off Road (Bob), Boyce Equipment, Rock Mafia, bottomland4x4 (Eric V), Aaron871, Mudpro, Firetoy, Ricky and those "Farm/Big Dixe Bogger" guys on this board.

AXLE

I've shaved the pan and put in 1/2" plate. I cut around a 6" diameter hole which gave the Bull Gear around 1 1/2-2" internal clearance (enough for a bolt to clear if one lets go plus enough oil to run the street I hope). Normal dirrection is with the fill plug to the rear.

WMS 79 1/2" hubs out.

WMS 69 1/4" hubs in.

WMS narrowed is 72" I think.

AXLE STRIPPING

RR AXLE

Torch out or grind/chisel the rivet heads FLUSH on the inner side of the backing plate axle flange, smack the backing plate brake assembly with a sledge hammer to drive it off the flange. I've done 14 axles now and this is the easiest way I've found.

FRT AXLE

When taking the king pin caps off, don't lose the spacers under the plate. The spacers go under the top plate. The top and bottom bushing plates are different sizes. They'll stick to the grease and you'll about throw them away like I did.

FRONT AXLE INNER SEAL HOLDERS

Don't waste your time with a slide hammer. If the center section is out slide a 6' piece of pipe all the way through and smack it twice with a sledge hammer, it will sail out of there.

REAR HUB BRAKES

I'm gon'na run "hubs out" so I worked on a low buck hub disc brake set up for the rear. So far I've put in the 8 bolt hub drive pattern in a 2001 1 ton Chevy rear disc (this clears the hub seal) and mounted it to the Rockwell hub. Welded a flat plate extension off of the brake backing plate flange so I can run disc on all four corners. Planning to run 16.5 wheels with 6" backspacing, I figure most people bought their tires for 8 lug stuff anyway so this way they don't have to buy new tires. Can't run a pinion on the front 'cause I want to run lockouts (would have to be locked in all the time for brakes with the pinion brake). Ended up using Wilwoods on the rear since I had already put some on the front. It looked like I could have made a frt. caliper off a Chevy 4x4 fit but didn't persue it once I decided to go Wilwood.

FRONT HUB BRAKES

I had used the USA6X6 wheel hub brake adapters (see bottom of page for new setup) since I had 16.5 wheels, bought the brackets and adapter from Daniel. Bought the Wilwood calipers, disc and pads locally cheaper. If you use these get the 1" longer studs if you want a little thread beyond your lug nuts. If you have 20" or larger wheels I would go with the F550 Calipers and School Bus rotors instead.

USA6X6 brackets and aluminum hat adapters, He's up to $175 now on this, was like $125.

Wilwood Forged Dynalite 120-6814 around $125 each (Summit/Jegs). Rich stated Wilwood "Dynapro 6's" will work also, have more bite.

Wilwood Rotors 160-2894 LH & 160-2895 RH around $50 each (Summit/Jegs).

Wilwood Polymatrix Pads 7112 Series $40 to $175 (depending on compound).

Front USA6X6 adapters, buy the 1" longer studs so you will have extra lug stud thread sticking out. You will have to grind round the USA6X6 bracket edge so it will lay flat against the hub flange.

BULL GEAR

From JP Magazine- 8 bolts around bull gear 105 ft lbs, 4 main caps 175 ft lbs. Pinion nuts 300-400 ft lbs. All bolts are saftied/cotter keyed so they don't back off. Nuts on bull gear face opposite of inputs. One side of the bull gear is chamfered, I put it back in like it came out, on light rigs it probably doesn't matter anyway.

AXLE BOOTS

Get thick one piece ones that last!

HUBS

Inner and outer races are the same PN, bearings are different. Big bearing to the inside, hubs don't care which way they are flipped because the races are the same.

Wheel Bearings - Bearings 3994 and 392

(one of these bearings is the same as a 14 Bolt Gm, let me figure it out again)

Wheel Studs - Euclid brand PN is E-5871-R

Hub Race - Timken brand PN is 3920 (same race using both size bearings so you can flip it)

FRONT AXLE SHAFT U JOINT PART NUMBERS

Rockwell 750N

Precision U joint 898

GMB 230-0075

Size is 5 1/16" across X 1 5/8" caps

CENTER SECTION

I was told by George if you want to flip it 4 bolt holes line up (input to the left or right). You have to drill and tap the housing or drill the center section for the other bolts/studs to mount it.

There is a spacer under the frt pinion yoke and not the rr, don't let it fall out and lose it.

On the trucks the fill hole is to the rr on both axles.

Carrier Race - Timken brand PN is 394AS

Carrier Bearing - Bearing 395 and Race is 394A Timken Numbers, I also got an MS number of MS19081-103 (someone let me know if these are wrong)

Pinion Bearings - Bearing Small 22780 and Race Small 22720, Bearing Large 29585 and Race Large 29521 Timkens

Pinion Seal - 23695 ? (not sure of this number)

HD Chevy rr disc installed on Rockwell hub, Wilwood calipers on extensions welded to axle brake backing plate flange. (hard to see but you get the idea)

HD Chevy rr disc bolted to the Rockwell hub (drilled in the hub pattern) with calipers bolted to flat plat extensions welded to the Rock flange.

Welded and filled spiders, ground to balance it out.

My steering assist set up, 8" throw inline with tierod. You can mount this anywhere as long as you get the travel right and centered.

BELOW Pictures 2/09/12 Front Hub Disc spacer mount idea, using above Wilwood PN's

Rockwell Disc Brake

SSWaters, Feb 10, 2012

George G. came over to the house and got me thinking about front disc again, this is my after work brainstorming. The spacer replaces the above USA6X6 Adapter Plate.

It would be "hub out only".

If you wanted to run a larger outside diameter disc just make the caliper bracket taller accordingly.

Will probably counter sink the spacer to hub mount bolts or use flush heads (it bolts thru the hub sideways). Kind'a close to caliper like this but it was my first try. I guess you could weld this but I don't like welding hot roll DOM to cast, even if you're certified to weld iconel underwater on the moon or magnesium on venus.

Would use high strength cap head bolts on the rotor to spacer mount, just didn't have any at work. Would safety wire those also, like I did these, don't just trust locktite by itself on the disc.

The disc you have to grind a hair off each tang to slide it down on the hub (1/16" to 1/8"). Don't pay any attention to my scribbling on it.

The spacer is 7 1/2" OD by 1/2" wall DOM, could not find find 6 3/8" ID Tube at an affordable price for the weekend warrior (found it, just not affordable). Will have to grind out little "moons" in the bottom to clear the stud shoulders. ($65 delievered from Speedy Metals last week)

Since I had to go with 6 1/2" ID I shimmed this hub center with 20 gauge sheetmetal plates (Home Depot or Lowes), could use 18 or 22 gauge depending on your hub (I had bead blasted this one clean). 16 Gauge is way to tight, had to really beat in and got all jammed up. Would have went if I had ground the hub surface really smooth. Shim all the way around evenly before drilling hubs! Spacer bolts go through shims.

The Caliper mount is out of 3/8" thick steel, you will need 5" X 10" pice to make this.

Drill some holes, Tap some others, some grinding/cutting/fitting and no welding.

Last edited:

![rammount4[1].jpg](https://img.nc4x4.net/xf/attachments/0/613-56ac79a0f03c6aab79d9ed556120cbcf.jpg)

I thought the 'good' axle setup was the ones with large ass u-joints ? or is the boot only needed for the other, bendix? joints?

I thought the 'good' axle setup was the ones with large ass u-joints ? or is the boot only needed for the other, bendix? joints?