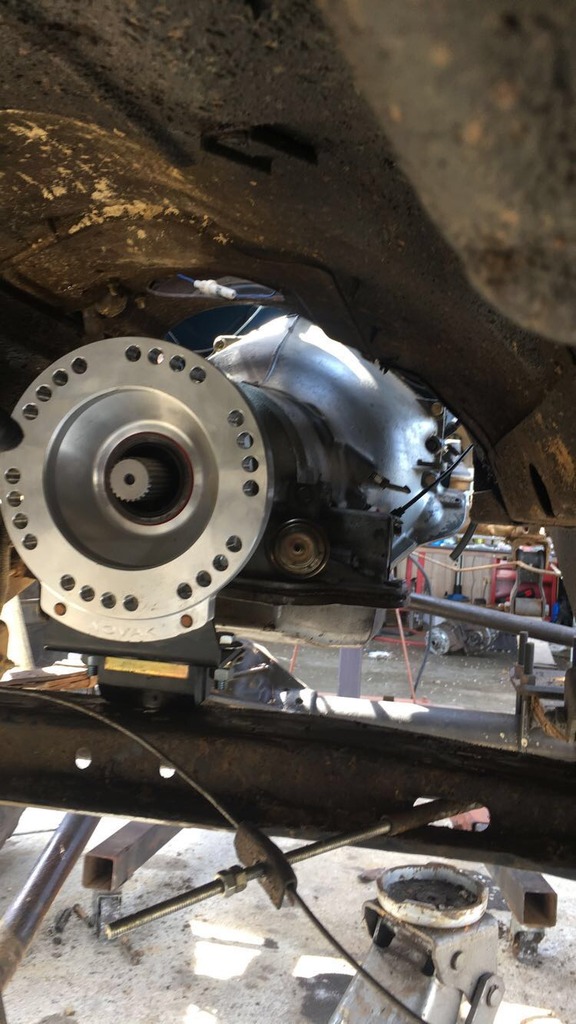

This build turned from shade tree to driveway really quick. The engine and transmission got mated and mounted. We found that the original cross member worked well bolted into a different location. The holes were already in a good spot as this truck came with quite a few engine and transmission options.

First the original motor mounts were removed. For some odd reason they were fastened in 2 ways, bolted through the frame and welded on top. We mounted the transmission to the engine, bolted the tq-converter to the flywheel and prepared to place it in the truck. Locktite was used adequately.

We placed the engine in to see where the motor mounts would be located and decided the best position for the cross-member.

There are 2 sets of holes in the frame. We moved the cross-member back to the second set of mounting holes and it put the engine mounts in the perfect spot. Hopefully this helps anyone looking to do a similar swap...

After getting the basic measurements we cut the cross-member to fit just inside of the frame. It is a tight fit.

And sat the motor into place!

Then burnt it in. After some prep to the surfaces obviously.

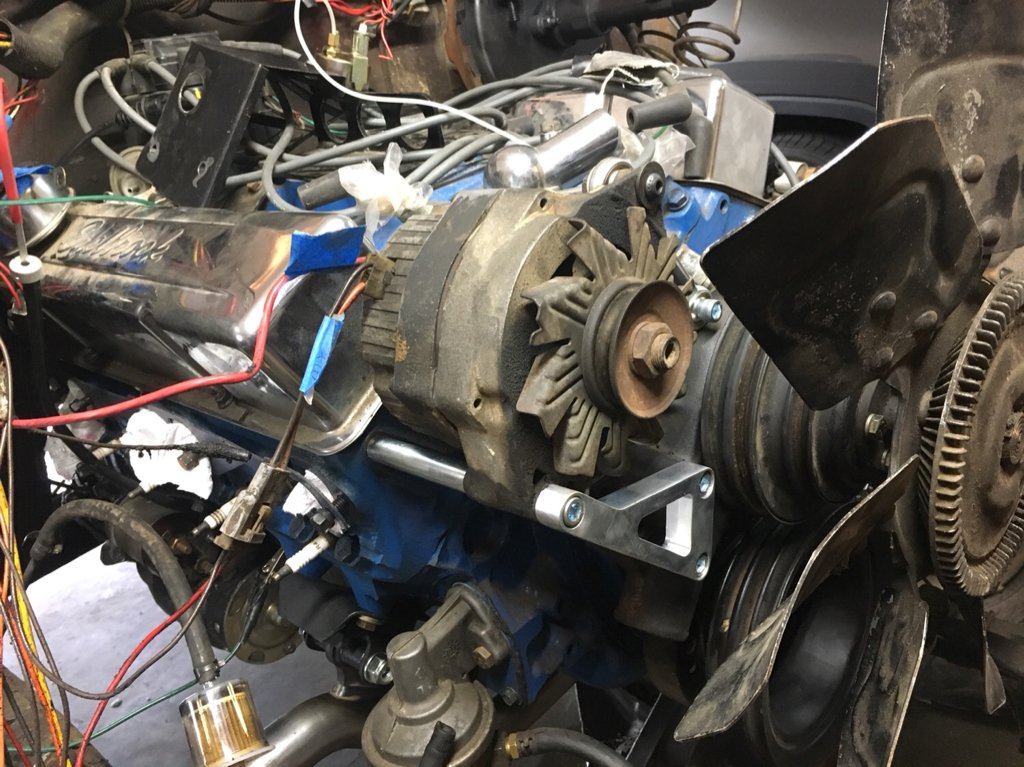

The motor is in and we made pretty decent time today. I started the day with the headers on the motor but they didn't agree with the driveshaft or the fire wall. The solution was shorty headers, and they are on the way. The exhaust plan is two into one and a turn down past the cab. The next step is accessorizing the motor with the alt, starter, PS pump, radiator, and a carb to make it run. Oh yeah, and the couple of wires and grounds and stuff.

I am considering gusseting the mounts on the bottom and sides where the tube meets the frame. not sure if it is necessary, but can't be too cautious. I will have safety chains/wires in place for if, I mean, when the rubber motor mounts break..

Anyone know of a Chevy radiator that fits in a FSJ with stock mounts?

Looking to have it done for the shakedown, first run of the year at URE!!