Exploderpilot

Well-Known Member

- Joined

- Mar 24, 2005

- Location

- Winston Salem, NC

I dont own a TTB nor do i have any intention of owning a TTB suspension but I do want to know what makes the TTB so un-desirable.

I have head and seen the cut and turned Beams flex very well with extended radius arms but people still swap out these nice TTB setups for solid axles.

So my question is why dont more people cut and turn thier beams and run extended radius arms instead of dropping more money on a Solid axle swap and having to regear and lock teh front axle?

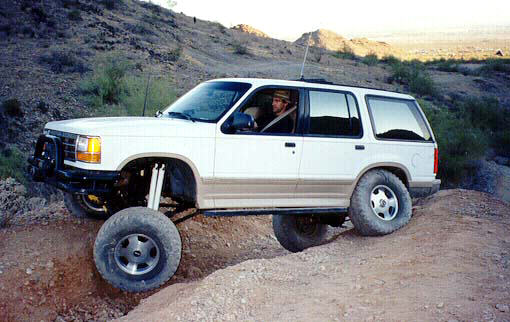

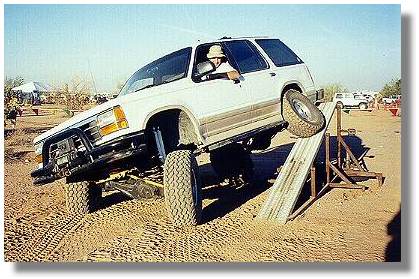

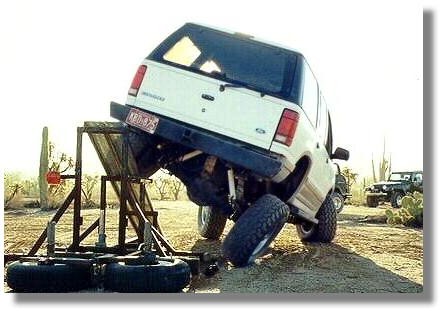

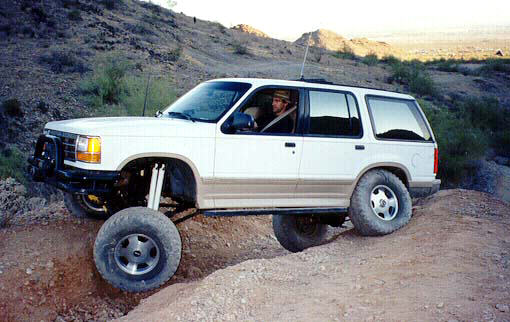

here is a nice TTB setup i found.

I have head and seen the cut and turned Beams flex very well with extended radius arms but people still swap out these nice TTB setups for solid axles.

So my question is why dont more people cut and turn thier beams and run extended radius arms instead of dropping more money on a Solid axle swap and having to regear and lock teh front axle?

here is a nice TTB setup i found.