We needed a replacement for my old Super Duty that we knocked a grand slam selling and I looked for several weeks. I need a reliable but not necessarily nice truck. Plane Jane is good and it doesn’t need anything but AC.

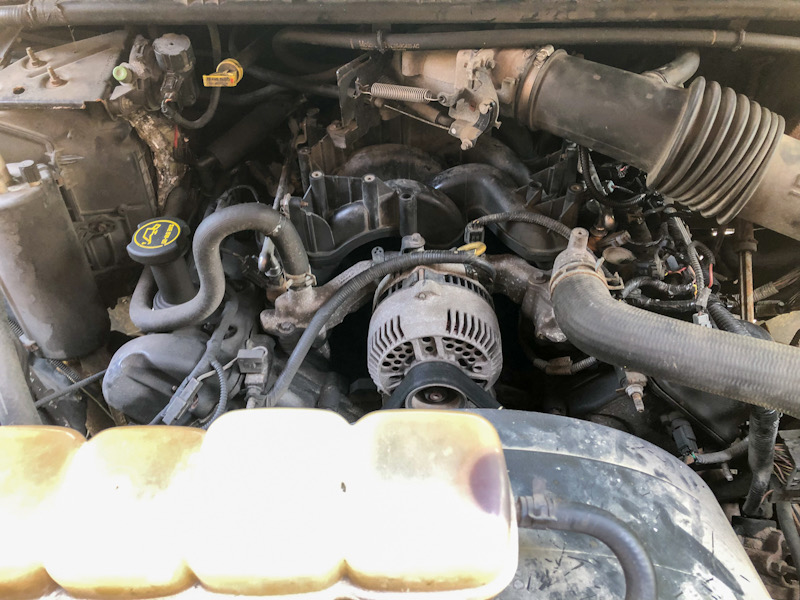

We found ‘Mater down in Mooresville for a great price. He’s a 2001 Super Duty 250XL with a good running 5.4 auto with 175k. He’s 4x4 with 4.10s and rear LS (10.5 TracLock is worthless) and some ghetto Dick Cepek wheels with decent 285 MTs.

My wife without hesitation said ‘Mater when I asked her to name him

He’s from PA so the bed has some iron worms but it’s not horrible. The cab and frame are solid.

Mater has stainless headers but they leak a bit. I already ordered and received a set of soft copper gaskets to fix that. He has a leak between the trans and case but not pouring. He needs front brakes.

The PO put in a rather nice bench from a late model F150 that is reminiscent of OBS seats and is comfortable.

I plan to start with cleaning up the inside and fixing the above mechanical issues and go from there. I envision ’Mater with DRW and a flat bed eventually but we’ll see how that progresses. Regardless the wheels have to go and a rear TruTrac will probably be added so it won’t be dangerous in the snow but have good traction

and a rear TruTrac will probably be added so it won’t be dangerous in the snow but have good traction

“It’s ’Mater like Tomater without the toe”

We found ‘Mater down in Mooresville for a great price. He’s a 2001 Super Duty 250XL with a good running 5.4 auto with 175k. He’s 4x4 with 4.10s and rear LS (10.5 TracLock is worthless) and some ghetto Dick Cepek wheels with decent 285 MTs.

My wife without hesitation said ‘Mater when I asked her to name him

He’s from PA so the bed has some iron worms but it’s not horrible. The cab and frame are solid.

Mater has stainless headers but they leak a bit. I already ordered and received a set of soft copper gaskets to fix that. He has a leak between the trans and case but not pouring. He needs front brakes.

The PO put in a rather nice bench from a late model F150 that is reminiscent of OBS seats and is comfortable.

I plan to start with cleaning up the inside and fixing the above mechanical issues and go from there. I envision ’Mater with DRW and a flat bed eventually but we’ll see how that progresses. Regardless the wheels have to go

“It’s ’Mater like Tomater without the toe”