NickMaul

Well-Known Member

- Joined

- Jul 4, 2009

- Location

- Norfolk, VA

After some coats of paint I take a sigh of relief when I slide the bumper on and bolt everything back together back to readiness condition. The winch and bumper is pretty hefty. Mind that I have not wound it back up with cable yet. Before cable I believe it is around 110#-125#. Just light enough for me to man handle and get it onto the body.

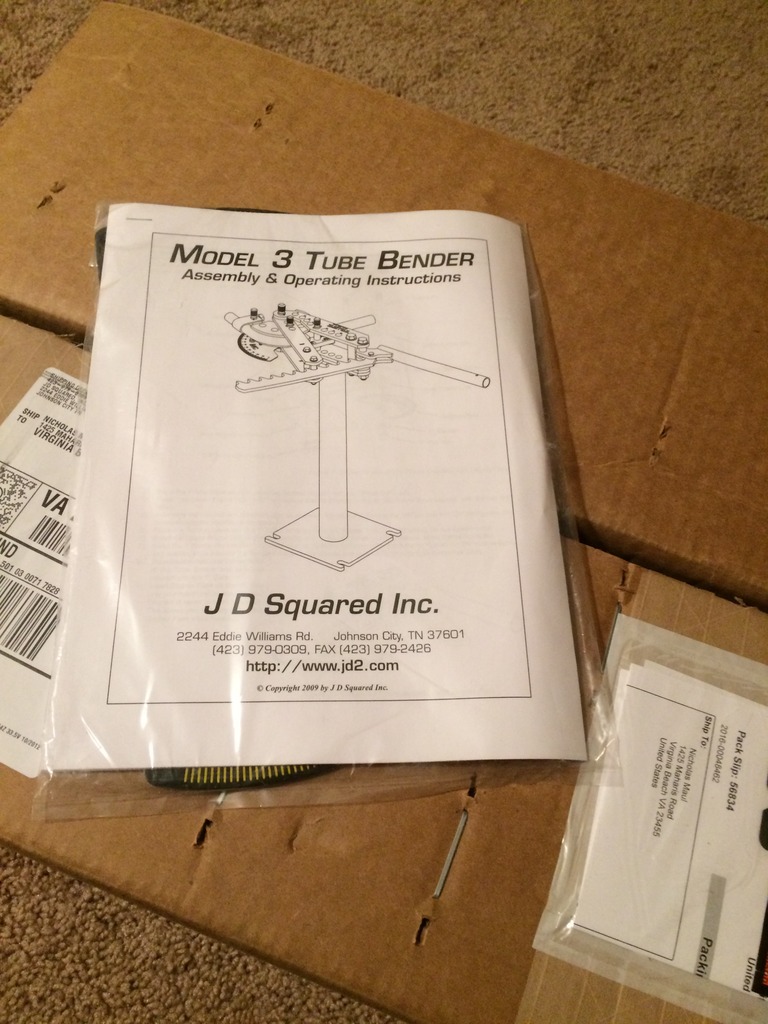

Really wish I had a tube bender by now. I don’t mind wheeling without some protection under the head lights but one bad kiss from a tree and I will be hunting in the junkyard for some new body parts

[/URL

[/URL

Really wish I had a tube bender by now. I don’t mind wheeling without some protection under the head lights but one bad kiss from a tree and I will be hunting in the junkyard for some new body parts

]

[URL=http://s978.photobucket.com/user/1tonoffun/media/jeep/F93EC8F6-089D-4FF8-8252-39B2749904B4_zpssdfztwtn.jpg.html]

]