- Joined

- Mar 17, 2005

- Location

- N. N. Raleigh, NC

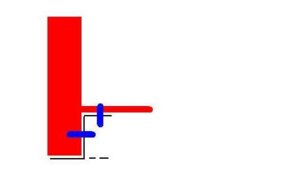

Ok, i got my camper jacks put on the camper. I made some plates ~8x10 that were welded into each corner with a socket that the jack plugs into.. The plates are welded around the edge and several plug welds.. The jacks are on ~16" stand offs. My plate and jack mount have little/no flex but the bottom framing of the camper is actually flexing this is causing the jacks to lean in and twist with the load....

This setup will suffice to allow me to get the trailer loaded up.. But not sturdy enough for long term use... So.... ideas ???

Only requirements is to lift it over the wheels and drive the trailer out... At this point I'm open to sugestions and crazy ideas... I really dont want to redo the camper sub frame.. Its not very heavy duty and has some fair amount of rust.. I'm sure i will need to be fully replace down the road.. NP as the rest is aluminum and in good shape..

Some I've thought about..

A ~fork type device that lifted the up from the side and pull it up and away from the trailer..

A device that lifted it up and back again pulling it above the wheels..

Pretty scary with this thing 3' in the air !!

This setup will suffice to allow me to get the trailer loaded up.. But not sturdy enough for long term use... So.... ideas ???

Only requirements is to lift it over the wheels and drive the trailer out... At this point I'm open to sugestions and crazy ideas... I really dont want to redo the camper sub frame.. Its not very heavy duty and has some fair amount of rust.. I'm sure i will need to be fully replace down the road.. NP as the rest is aluminum and in good shape..

Some I've thought about..

A ~fork type device that lifted the up from the side and pull it up and away from the trailer..

A device that lifted it up and back again pulling it above the wheels..

Pretty scary with this thing 3' in the air !!